Investing in your production line is a significant decision. The world of packaging machinery is vast, filled with complex terminology and a dizzying array of equipment options. Making the wrong choice can lead to costly inefficiencies and operational bottlenecks, turning a potential asset into a liability. The fear of a misplaced investment can be paralyzing, leaving you unsure how to move forward with confidence.

This comprehensive guide is engineered to eliminate that uncertainty. We provide the clarity and expert insight necessary to build a high-performance, reliable production line. We will walk you through every critical stage, from initial product filling and capping to final case packing and palletizing. You will gain a practical understanding of each machine’s function and learn how different components integrate into a cohesive, efficient system.

By the end of this guide, you will be equipped to identify your exact needs, evaluate equipment with an expert eye, and engage with manufacturers as an informed partner. Consider this your roadmap to making a confident, strategic investment that delivers a powerful return and drives long-term success for your business.

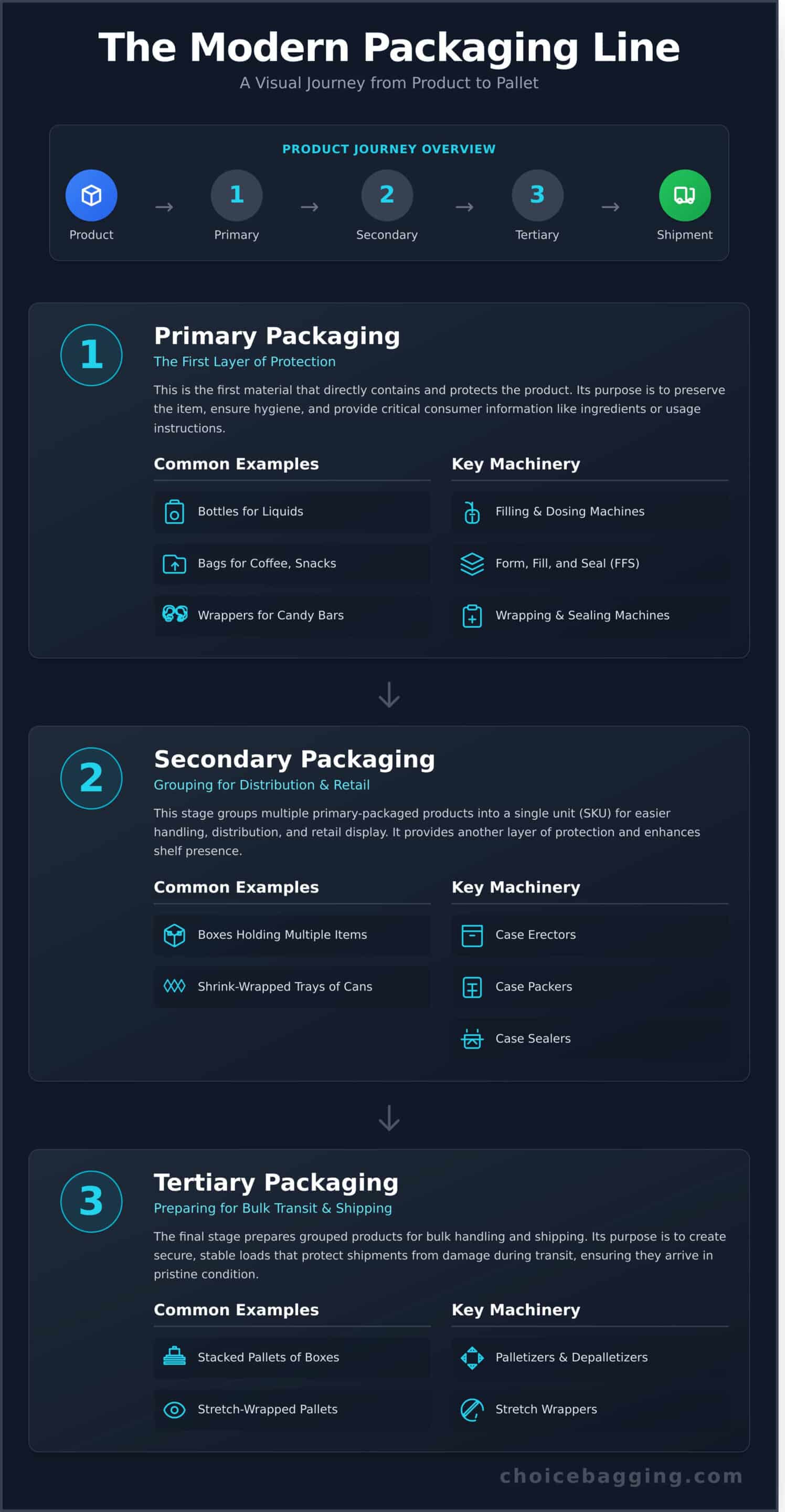

The Modern Packaging Line: Primary, Secondary, and Tertiary Stages

A modern packaging line is engineered for one primary goal: to move products from production to the end-user with maximum efficiency, safety, and brand consistency. This systematic process relies on high-performance packaging machinery to execute a series of standardized steps. To understand how automation enhances this journey, it’s essential to first grasp the three core stages of packaging. This structure, from the initial wrap to the final pallet, ensures every item is protected and prepared for distribution. For a broader Packaging machinery overview, this resource provides excellent foundational knowledge on the equipment that drives these processes.

Product Journey Through Packaging Stages

Product → Primary Packaging → Secondary Packaging → Tertiary Packaging → Shipment

Primary Packaging: The First Layer of Protection

Primary packaging is the first material that directly contains and protects the product. Its fundamental purpose is to preserve the item, ensure hygiene, and provide critical consumer information like ingredients or usage instructions. This stage is vital for both product integrity and compliance with industry regulations, serving as the first point of contact with the customer.

- Examples: Bags for coffee beans, bottles for liquids, and wrappers for candy bars.

Secondary Packaging: Grouping for Distribution

Secondary packaging groups multiple primary-packaged products into a single stock-keeping unit (SKU). This stage simplifies handling for distributors and retailers while offering another layer of protection. It also serves as a key marketing tool, providing the “shelf presence” that attracts customers in a retail environment. Efficient secondary packaging is critical for streamlined inventory management.

- Examples: Cardboard boxes holding multiple cereal bags or shrink-wrapped trays of canned goods.

Tertiary Packaging: Preparing for Transit

The final stage, tertiary packaging, prepares grouped products for bulk handling and shipping. Its purpose is to protect shipments from damage during transit and storage, ensuring they arrive at their destination in pristine condition. This is where robust end-of-line packaging machinery, like palletizers and stretch wrappers, demonstrates its value by creating stable, secure loads for logistics.

- Examples: Multiple boxes stacked on a pallet and secured with stretch wrap or strapping.

Key Machinery in Primary Packaging

Primary packaging is the critical first layer that directly contains and protects your product. The selection of the right packaging machinery at this stage is dictated by the product’s physical form—whether it is a liquid, solid, powder, or granule. The primary goals are always precision, operational speed, and uncompromising product integrity. Consequently, equipment must be built for performance and reliability, often utilizing materials like food-grade stainless steel to meet stringent safety and regulatory standards.

Filling and Dosing Machines

At the core of primary packaging is the accurate dispensing of your product. Filling and dosing machines are engineered for precision to minimize waste and ensure consistency. The technology varies by application:

- Auger Fillers are ideal for powders and fine granules, using a rotating screw to dispense a precise volume.

- Piston Fillers handle liquids and pastes, from water-thin to viscous, with exceptional accuracy.

- Weighers (like multi-head weighers) are used for solids, measuring by weight to fill bags with products like snacks or hardware.

Specialized equipment like Valve and Open Mouth bag fillers fall into this category, designed for high-performance dosing of bulk materials into pre-made bags.

Form, Fill, and Seal (FFS) Machines

For maximum efficiency, Form, Fill, and Seal (FFS) machines automate three steps into one seamless process. These systems create, fill, and seal a package from a continuous roll of film. The efficiency of FFS systems is a key driver in their widespread adoption, a trend reflected in a recent packaging machinery industry report that projects significant market growth. The two primary types are:

- Vertical FFS (VFFS): For products that can be dropped by gravity, such as coffee, sugar, and liquids, into a tube of film that is sealed to form a bag.

- Horizontal FFS (HFFS): For solid, single-item products like candy bars or medical devices that are placed onto a flat film and then wrapped.

Wrapping and Sealing Machines

Once a product is filled, it must be securely sealed. This final primary step is essential for shelf life, safety, and presentation. This category of packaging machinery includes a wide range of solutions, from flow wrappers that tightly wrap individual items to simple heat sealers that provide a durable closure for bags and pouches. For retail, specialized equipment like blister packaging and clamshell sealers offer both product protection and high visibility. A reliable, high-integrity seal is non-negotiable, as it prevents contamination and provides tamper evidence.

Essential Secondary and Tertiary Packaging Machinery

Once your product is in its primary package, the focus of automation shifts from the individual item to the case and pallet. This is the core of end-of-line automation, where secondary and tertiary packaging machinery takes over to prepare goods for bulk handling, storage, and shipping. Implementing automation here dramatically reduces strenuous manual labor, minimizes errors, and drives significant improvements in shipping efficiency and throughput.

Case Erectors, Packers, and Sealers

This sequence of equipment forms the foundation for preparing products for shipment. Each machine performs a critical, high-repetition task with unmatched speed and consistency.

- Case Erectors automatically pull flat cardboard blanks, form them into boxes, and seal the bottom flaps, presenting a perfectly constructed case for filling.

- Case Packers then place your products into the erected cases. This can be done with gentle robotic arms for delicate items or high-speed drop packers for more durable goods.

- Case Sealers complete the process by applying tape or glue to securely seal the top flaps, ensuring the case is ready for palletizing.

Labeling and Coding Equipment

In modern logistics, data is as important as the product itself. Labeling and coding equipment ensures every case is tracked and compliant. Print-and-apply labelers affix shipping labels with barcodes and logistical information, while high-speed inkjet or laser coders print essential data like lot numbers, batch codes, and expiration dates directly onto the case. This machinery is essential for maintaining supply chain visibility, ensuring traceability, and meeting regulatory requirements.

Palletizing and Stretch Wrapping Machines

The final step in end-of-line automation is preparing cases for stable and secure transit. Robotic palletizers are a cornerstone of modern systems, engineered to stack cases onto a pallet in a precise, predetermined pattern that maximizes stability and load density. This automation enhances worker safety by eliminating the need for manual heavy lifting. Once the pallet is built, a stretch wrapper tightly binds the load with film, protecting it from shifting, moisture, and damage during shipment.

Integrating this level of sophisticated packaging machinery requires expert consultation to ensure seamless performance. To discuss how to build a reliable and efficient end-of-line system, contact the engineering team at choicebagging.com.

How to Select the Right Packaging Machinery

Choosing the right end-of-line equipment is a significant capital investment that demands careful, systematic planning. The decision you make directly impacts production speed, operational costs, and your ability to scale for future growth. A common mistake is focusing solely on the initial purchase price. Instead, a successful selection process evaluates the total cost of ownership, which includes factors like maintenance requirements, parts availability, potential downtime, and the quality of long-term support. Investing in the right packaging machinery from the start ensures reliability and a stronger return on investment for years to come.

Analyzing Your Product and Production Needs

The foundation of a smart equipment choice is a deep understanding of your specific application. Before evaluating any machines, document your operational requirements with precision. This clarity prevents costly mismatches between the equipment’s capabilities and your daily demands.

- Product Characteristics: Consider the size, weight, form (solid, liquid, powder), and fragility of your product. Abrasive materials may require more durable stainless steel components, while fragile items need gentle handling systems.

- Required Throughput: Define your target production rate in units per minute or hour. Be sure to account for both current needs and projected future increases in volume.

- Future Scalability: Will you be introducing new product lines or package sizes? Select machinery that offers the flexibility to adapt to your evolving business needs.

Evaluating Automation and Integration Requirements

Effective automation seamlessly fits into your existing facility and workflow. Assess your operational environment to ensure the new equipment enhances, rather than complicates, your production line. Key technical considerations include the desired level of automation—from manual and semi-automatic to fully automatic systems—and how the new machine will integrate with upstream and downstream equipment. You must also verify practical site requirements, including available floor space, power supply, and compressed air capacity.

Choosing a Machinery Partner, Not Just a Supplier

The manufacturer you choose is as important as the machine itself. Look for a partner with proven experience and a reputation for building durable, high-performance equipment. A reliable manufacturer stands behind their products with comprehensive support, operator training, and readily available replacement parts to minimize downtime. They should act as an extension of your team, offering expert consultation to ensure you get a solution truly engineered for your success. True partners are invested in your long-term efficiency and growth.

Ready to find a reliable solution? Consult our experts to design your ideal packaging line.

Your Partner in Production Line Integration

Designing an efficient production line begins with a clear understanding of the primary, secondary, and tertiary stages of packaging. As we’ve covered, selecting the right packaging machinery is a critical decision that impacts everything from product safety to operational throughput. It requires a strategic approach that considers not just individual machine capabilities, but how each component integrates to form a seamless, high-performance system.

Making that investment confidently is easier with an experienced partner. Since 1978, Choice Bagging Equipment has been a trusted manufacturer of reliable, USA-made equipment. We are more than just a supplier; we are your partner in production line integration, dedicated to ensuring your success. Let our expertise guide you to the perfect configuration for your specific needs.

Ready to build a more efficient and reliable production line? Speak with a Choice Bagging expert to configure your equipment. We look forward to helping you achieve your production goals.

Frequently Asked Questions About Packaging Machinery

What is the difference between a bagging machine and a VFFS machine?

The primary difference is the source of the bag. A standard bagging machine fills and seals pre-made bags that are fed into the system. In contrast, a Vertical Form Fill Seal (VFFS) machine creates the bag from a continuous roll of flat film, forms it into a tube, fills it with product, and then seals it. VFFS systems are typically used for higher-speed, high-volume applications, while baggers offer flexibility for various pre-made bag types.

How do I calculate the ROI on investing in new packaging machinery?

A reliable ROI calculation compares your total investment cost against the net financial gain. The basic formula is (Gain from Investment – Cost of Investment) / Cost of Investment. Gains include measurable increases in throughput, reductions in labor costs, and minimized material waste. Your total cost should include the machine price, installation, training, and planned maintenance. This analysis will clarify how quickly your new packaging machinery will deliver a positive financial return.

What are the most important safety features to look for on packaging machines?

Operator safety and equipment reliability are paramount. Key features include highly visible emergency stop (E-stop) buttons, safety interlocks on all access doors that halt the machine when opened, and light curtains that create a protective field around hazardous areas. Comprehensive physical guarding around all moving parts is also non-negotiable. These systems are essential for ensuring a safe work environment and meeting regulatory compliance standards for your facility.

How much floor space is typically required for a complete packaging line?

Floor space requirements depend entirely on the line’s complexity. A single, standalone machine might only need 100-200 square feet. However, a complete automated line—including conveyors, a bagger or case packer, a checkweigher, and a palletizer—can easily require 1,000 square feet or more. A professional layout consultation is the best way to determine the precise footprint needed to optimize material flow, operator access, and overall efficiency for your specific operation.

Can packaging machinery handle sustainable or eco-friendly materials?

Yes, modern packaging equipment is engineered to work with a growing range of sustainable materials. Many machines can effectively run recyclable mono-material films, compostable plastics, and paper-based bags. Because these materials have unique properties, it is critical to consult with your equipment manufacturer to confirm compatibility. Running material trials ensures your machine is calibrated for optimal performance, seal integrity, and reliable throughput without sacrificing quality.

What is the typical lead time when ordering new packaging equipment?

Lead times vary based on machine customization and current production schedules. A standard, in-stock machine can often be delivered in 4 to 8 weeks. For custom-engineered solutions or fully integrated packaging lines, lead times typically range from 16 to 24 weeks or more. This allows for detailed engineering, component sourcing, assembly, and rigorous factory acceptance testing to ensure your equipment meets performance specifications upon arrival.

Recent Comments