Bulk Bag Unloaders & Discharger Systems

CBE offers high-quality bulk bag unloaders (also called bulk bag dischargers) for emptying powders, granules, pellets, and flaked materials from bags. Moreover, we can create turn-key systems to unload bulk bag contents into equipment for repacking or other processing. Safety is also a priority in the design of these machines. Thus, our unloaders offer secure handling and improved control while lifting and positioning bags into their support framework.

Our bulk bag unloaders come in forklift as well as hoist and trolley style configurations. They are intentionally overbuilt because of the heavy loads they must support. In addition, the machines have integrated conditioning devices to help compacted materials flow more smoothly. Lastly, they come with sealed untie boxes for safe and clean access when untying and feeding product into the filler below.

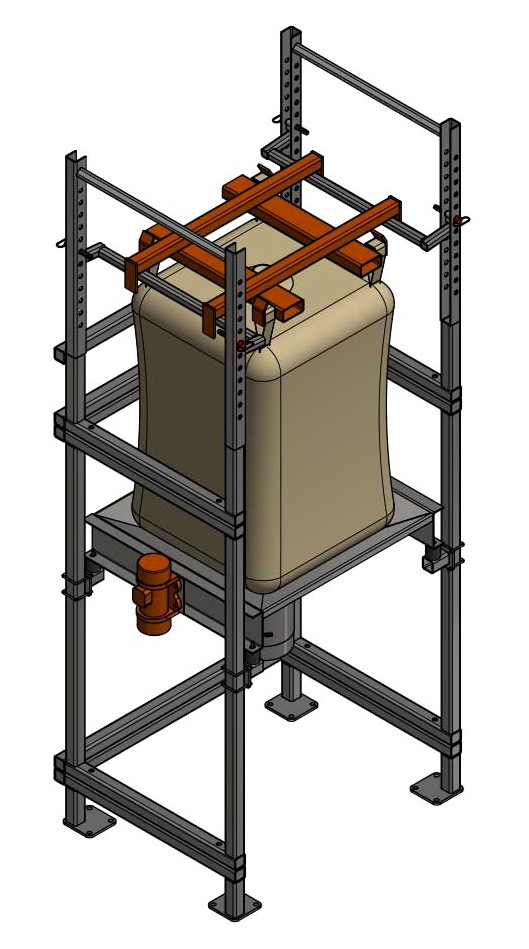

Model 4100 Heavy Duty Bulk Bag Unloaders are designed to be forklift loaded. They can handle bag sizes up to 48″ (122 cm) long, 48″ (122 cm) wide, and 54″ (137 cm) tall. These specifications do not include bag straps and assume 10″ (25 cm) long bag strap loops. Control Air 80 PSI is also required @ 1 cfm per bag fill cycle for this equipment (the base unit requires no compressed air).

Proper Applications: Free flowing & semi-free flowing powders

Weight Range: 550-3,000 lb. (250-1,350kg) bulk bags

Dimensions: 180″ tall x 68″ wide x 68″ deep (60″ between legs)

Electrical: 115 Volt, 1 phase, 60 cycle (hoist – 220/440 volt / 3 phase, 60 cycle) (base unit requires no electrical power)

Dust Collection Pickup: Minimum 400 cfm (base unit not supplied w/ dust collection take-off connection)

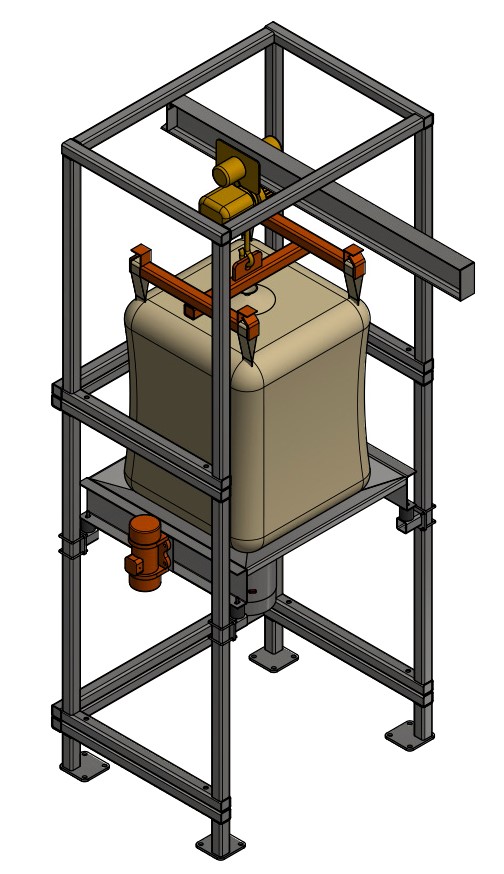

Model 4200 Heavy Duty Bulk Bag Unloaders are designed to be hoist or trolley loaded. They can handle bag sizes up to 48″ (122 cm) long, 48″ (122 cm) wide, and 54″ (137 cm) tall. These specifications do not include bag straps and assume 10″ (25 cm) long bag strap loops. Control Air 80 PSI is also required @ 1 cfm per bag fill cycle for this equipment (the base unit requires no compressed air).

Proper Applications: Free flowing & semi-free flowing powders

Weight Range: 550-3,000 lb. (250-1,350kg) bulk bags

Dimensions: 180″ tall x 68″ wide x 68″ deep (60″ between legs)

Electrical: 115 Volt, 1 phase, 60 cycle (hoist – 220/440 volt / 3 phase, 60 cycle) (base unit requires no electrical power)

Dust Collection Pickup: Minimum 400 cfm (base unit not supplied w/ dust collection take-off connection)

Bulk Bag Unloading System Types

Choice Bagging Equipment, Ltd. offers two types of heavy-duty bulk bag unloading systems, designed to discharge and condition 1,000-4,400 lbs bulk bags, with free flowing powders, granular or pelleted materials, into downstream processes or bag filling equipment.

All CBE bulk bag unloaders are designed to handle the following bags:

Bag Styles Handled: Spout Bottom and Block Bottom Bulk Bags

Maximum Bag Size: 44” X 44” X 72”

Maximum Weight Load: 4,000 Lb. (1,818 KG)

Hoist Style Bulk Bag Unloaders:

To use a hoist-style bulk bag unloader, an operator will lower the hoist mounted bag lift rack over a bulk bag setting at floor level. They will then secure the bag lift straps using the pendant controls and will then lift the bag up into the support structure of the unloader. From the operator’s platform, an operator will untie the discharge spout of the bag inside of the untie box and allow product to flow out.

Common Features of a Bulk Bag Discharger

A bulk bag discharger is highly versatile, great for use in almost any manufacturing or production environment. Choice Bagging equipment accommodates most commonly used bulk bag types, typical bag contents and the material that these systems work with. CBE bulk bag dischargers eliminate dangerous situations like disconnections, dead spots, or complex manual operation.

Benefits of using a Bulk Bag Unloader

Bulk bag unloaders are proven to help companies reduce waste and save money, and come in a variety of designs or configurations, to meet the needs of any enterprise. A few of the primary benefits of using a bulk bag unloader include:

Decreased strain on resources

as less manpower is needed to receive and disburse material into processing lines.

Highly customizable designs

including full and half-frame configurations, hoist and trolley systems, bag dump station, sifters and lump breakers, discharge valves or conveying system integration, just to name a few.

Improved productivity

as machinery is used to do all heavy lifting and moving, with easy-to-use controls for operators.

Reduced dust and product loss

due to the dust-free discharge and sealing process

Improved sanitation

of your end product, as filters protect the product stream from foreign materials.

Increased durability

due to CBE’s strong, durable and long lasting design

Which Bulk Bag Unloader is Best For Your Needs?

Choice Bagging Equipment representatives are your expert guides to which bulk bag unloader will meet your business needs. Contact us today to reach a trained Choice Bagging Equipment specialist!

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed