Bulk FIBC Bag Fillers

Choice Bagging manufactures a complete line of heavy-duty bulk bag fillers for manual and automatic bagging systems. Our bulk bag fillers deliver performance and reliability for many applications including dry powders, granulated products, and flaked materials. All bulk bag fillers also include dust-tight fill heads and controlled dust takeoff systems preventing contamination and leakage. Lastly, they’re constructed of continously welded, heavy-wall 4″ box tubing and have integrated scales.

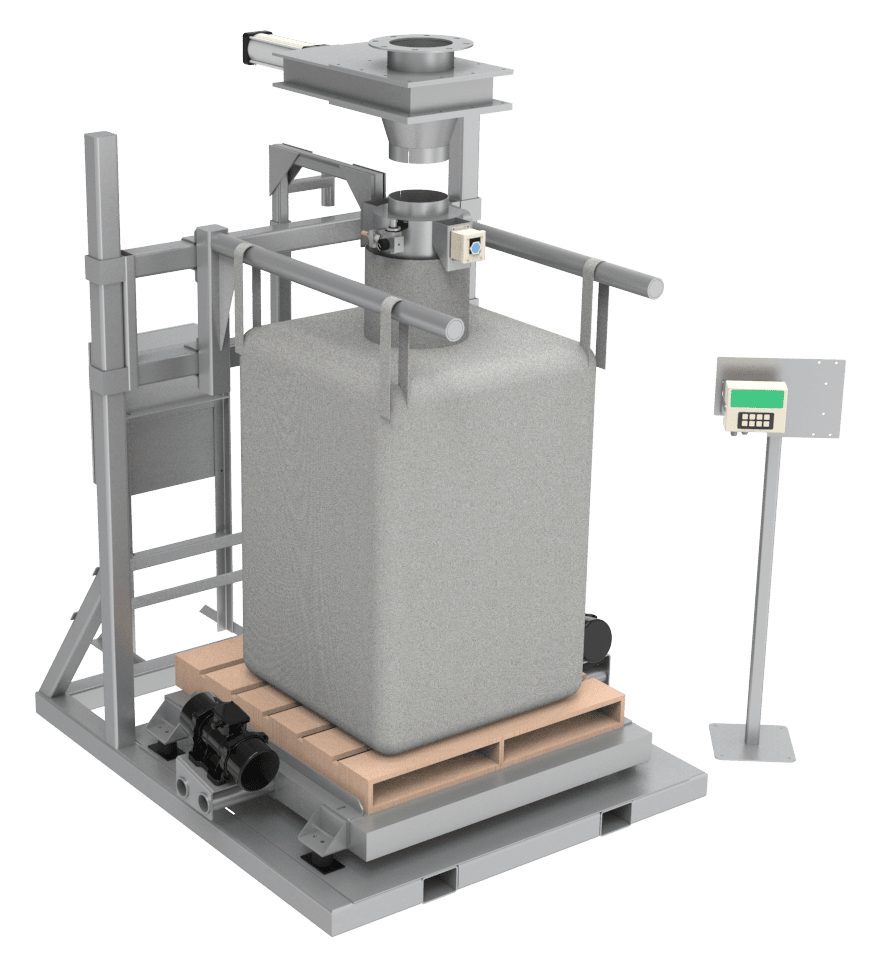

Heavy-Duty Bulk Bag Filling Machine

Model 5100

Ideal for applications with low to moderate production requirements. Configurable for a wide range of powders, flakes, and granules.

Examples of materials this machine bags: mortars, hydrated lime, gypsum, bentonite, barite, pigments, fertilizer, plastic pellets, plastic resins, calcium carbonate, starch, corn flour, oat flour, powdered sugar, hard grains.

Fills up to 10 bags per hour.

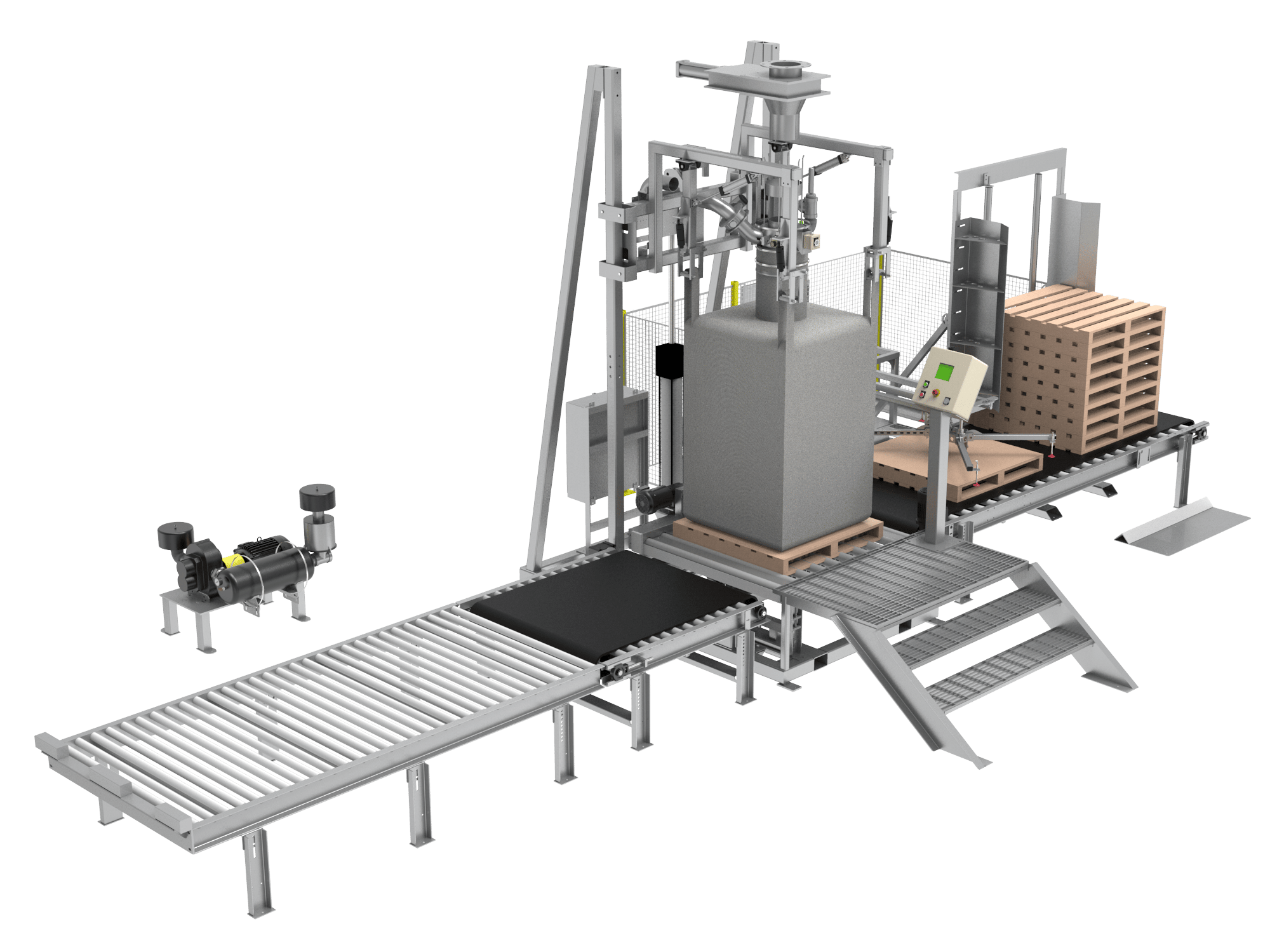

High-Speed Bulk Bag Filling Machine

Model 5200

Intended for packaging needs with moderate to high production output and oversized FIBC bags. This machine can be set up for many types of powders, flakes and granules.

Examples of materials this machine bags: mortars, hydrated lime, gypsum, bentonite, barite, pigments, fertilizer, plastic pellets, plastic resins, calcium carbonate, starch, corn flour, oat flour, powdered sugar, hard grains.

Fills up to 25 bags per hour.

What is a Bulk Bag Filler?

Primarily intended for agricultural and industrial uses, bulk bag fillers are a versatile, efficient, economical packaging solution. They can be operated manually or automatically and handle a wide range of dry powder, granulated, and flaked materials. This is why bulk bag fillers typically package fertilizer, food grains, seeds, flour, sugar, salt, and animal feed. However, they can also bag industrial minerals and chemicals.

What Types of Bulk Bag Fillers are there?

The two classes of bulk bag fillers are suspended “hanging” fillers and bottom supported “platform” fillers. Both can be built with either a gross or net weigh scale. Gross weigh scales simultaneously fill and weigh bags, while net scales pre-weigh and fill as a secondary step. Lastly, most bulk bag fillers are gravity fed by slide-gate or butterfly valve, or fed by rotary valve or auger.

Examples of Materials Packaged with Bulk Bag Fillers:

Building Materials

Cement, Concrete, Flyash, Mortars, Hydrated Lime, Plaster, Refractories, Sand, Gravel

Industrial Materials

Calcium Carbonate, Kaolin Clay, Talc, Alumina, Graphite, Barite, Bentonite, Gypsum, Coal

Industrial Chemicals

Plastic Pellets, Fertilizer, Pigments, Zinc Oxide, TIO2, Iron Oxide, Carbon Black

Food Products

Wheat Flour, Corn Flour, Oat Flour, Sugar, Salt, Spices, Cake Mixes, Cocoa Powder

Agricultural

Animal Feed, Corn, Soybeans, Seed, Feed, Fertilizer,

Wood Pellets

Capabilities of Bulk Bag Filler Systems

Choice Bagging bulk bag fillers can package 1,000 to 4,400 lb (454-2,000KG) bags. The materials they support include non-dusty powder, flaked, or granular products. They can also run at production speeds of up to 25 bags per hour.

Finding the Right Bulk Bag Filler

Choosing the proper bulk bag filler can be difficult because so many factors need to be considered. These include the bag type you’re using, the speed at which you need them filled, and your budget. All of these elements and more will influence your decision. However, the good news is that bulk baggers can be customized to meet almost any need you may have. Contact Choice Bagging today and let us simplify the process of finding the right machine for you!

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed