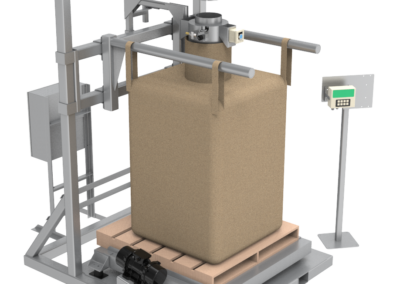

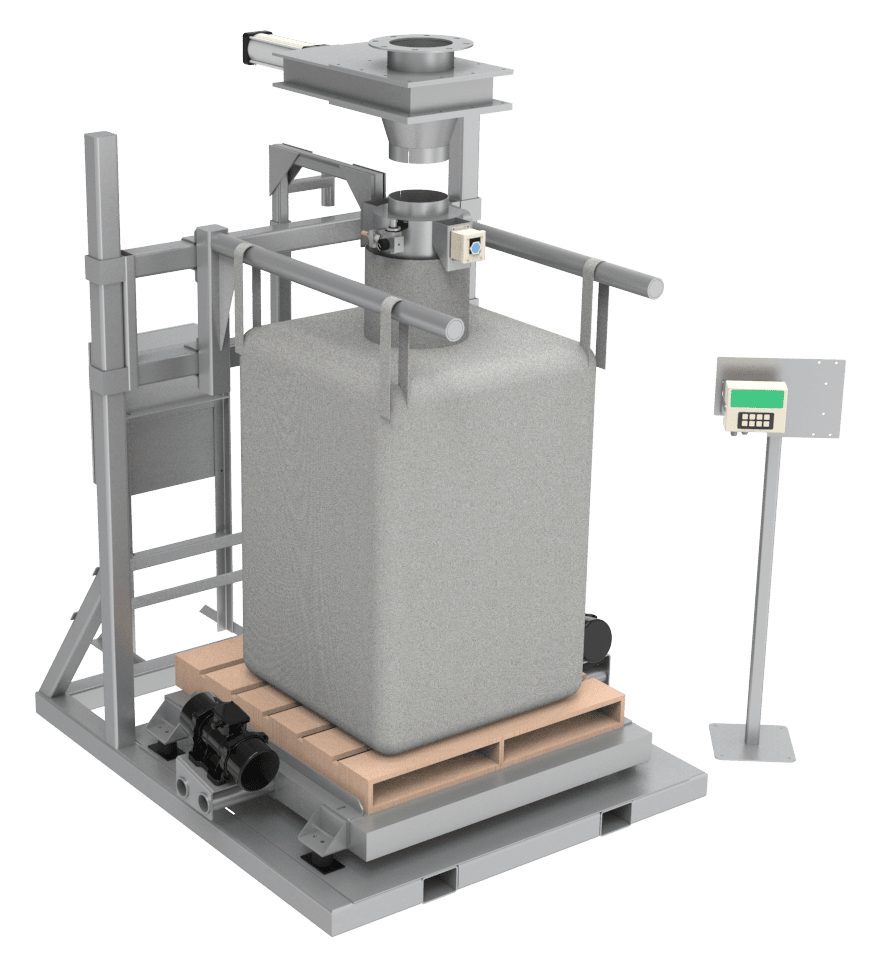

Heavy-Duty Bulk Bag Filler

Model 5100

The Model 5100 Bulk Bag Filler is configurable for many types of powders, flakes and granules. It is best suited for low to moderate output requirements. The use of slide gates, augers, or rotary air locks for feeding greatly increases its material handling range. A digital scale fills bags accurately with tight tolerances. The continuously welded, heavy wall, tubular support framework provides durability and reliability. An inflatable bag seal cuff securely holds the bag neck for dust-free filling. The 5100 also offers options to increase efficiency including a pre-fill inflator that stretches bags to full capacity and a densifier integrated into the scale to settle material during filling.

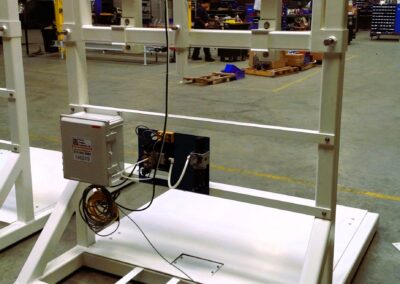

Click Images for Larger Views

Click to View Video

Model 5100 Bag Lift & Bag Inflator Demonstration

Examples of Materials Bagged with this Machine

Mortars, hydrated lime, gypsum, bentonite, barite, pigments, fertilizer, plastic pellets, plastic resins, calcium carbonate, starch, corn flour, oat flour, powdered sugar, hard grains

Granules

Powders with fine granules

Flakes

Specifications:

Bag filling weight range: 1,000-4,400 lbs. (454-2,000 kg)

Production rate: Up to 10 bags per hour (material and bag size dependent)

Material density range: 35-150 lbs. (15.9-68 kg) per cubic foot

Operating modes: Semi-automatic (operator assisted)

Maximum recommended bag size: 65” overall height

Bag types: Spout type poly woven bags and super sacks

NOTE: This filler is capable of bagging both flowing and non-free-flowing materials. Additional specialized product feeding devices may be required. The standard design can handle dry, free-flowing, and low humidity materials.

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed