Industrial Bag Handling Conveyor Systems

Our bag conveyor systems perform many actions supporting the bagging process including tipping, flipping, turning, straightening, and flattening. They can also checkweigh, print, label, and transport filled bags. In short, everything needed from bag filling to palletizing. Additionally, we provide world-class conveyors for bag transfer, incline, closing, v-through, and reject. Lastly, we offer bag kickers and weighers.

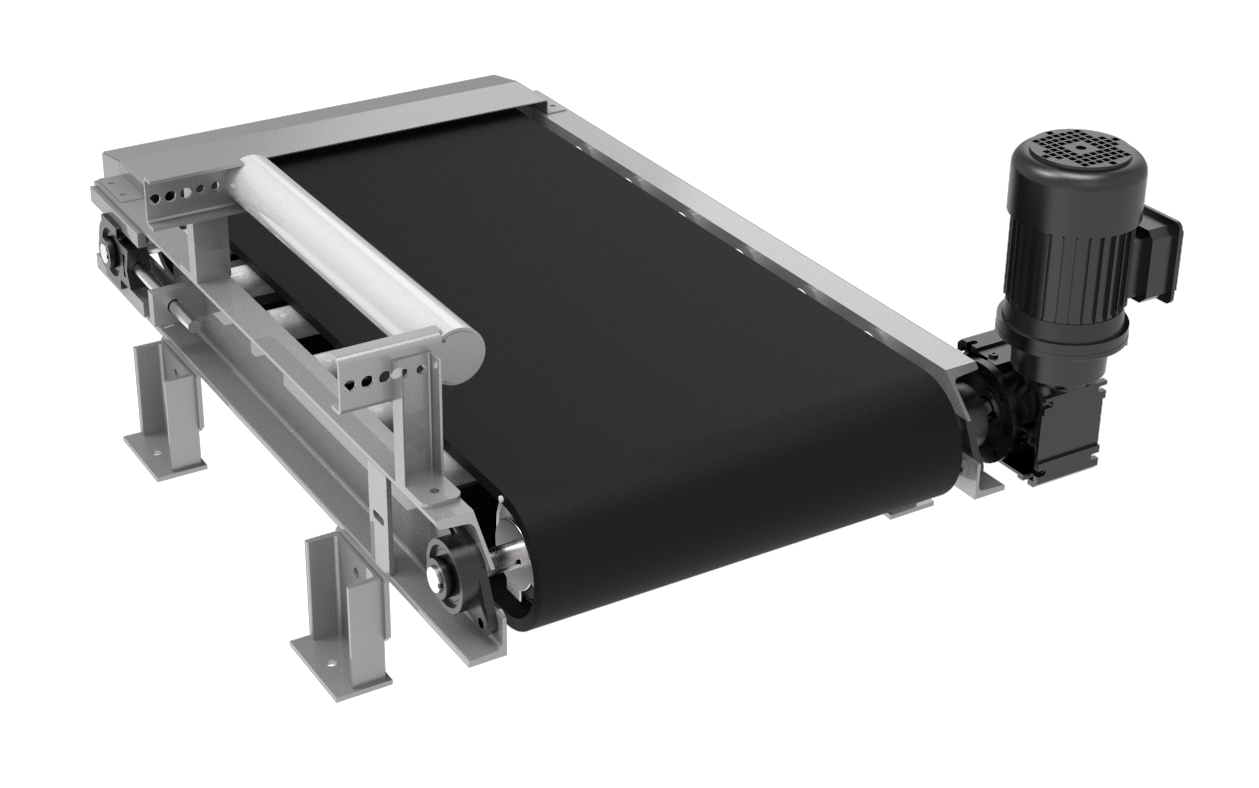

302 Series Bag Transfer Conveyors turn bags 90 degrees between conveyors as needed. They have 24” wide belts and come in lengths up to 16’.

(220/440V / 3 Ph / 60 Cycle Electrical Standard)

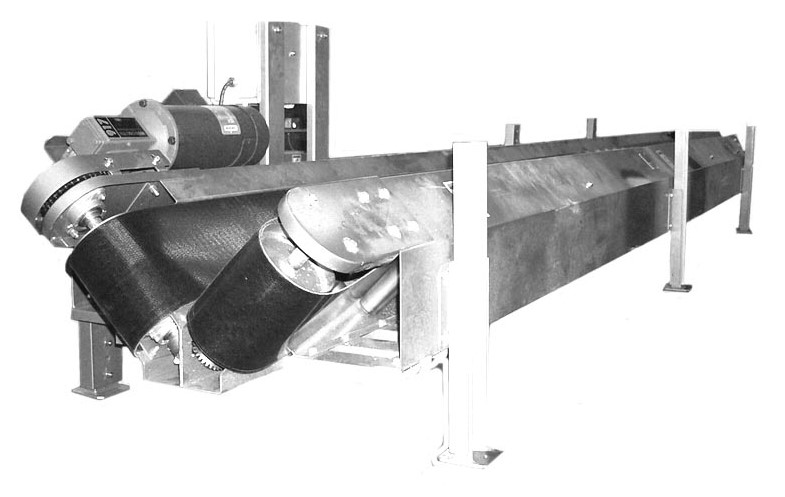

Our 303 Series Bag Incline & Transport Conveyor changes bag elevation and moves them as needed through bagging systems. It comes with a 24” wide belt in frame lengths up to 16’.

(220/440V / 3 Ph / 60 Cycle Electrical Standard.)

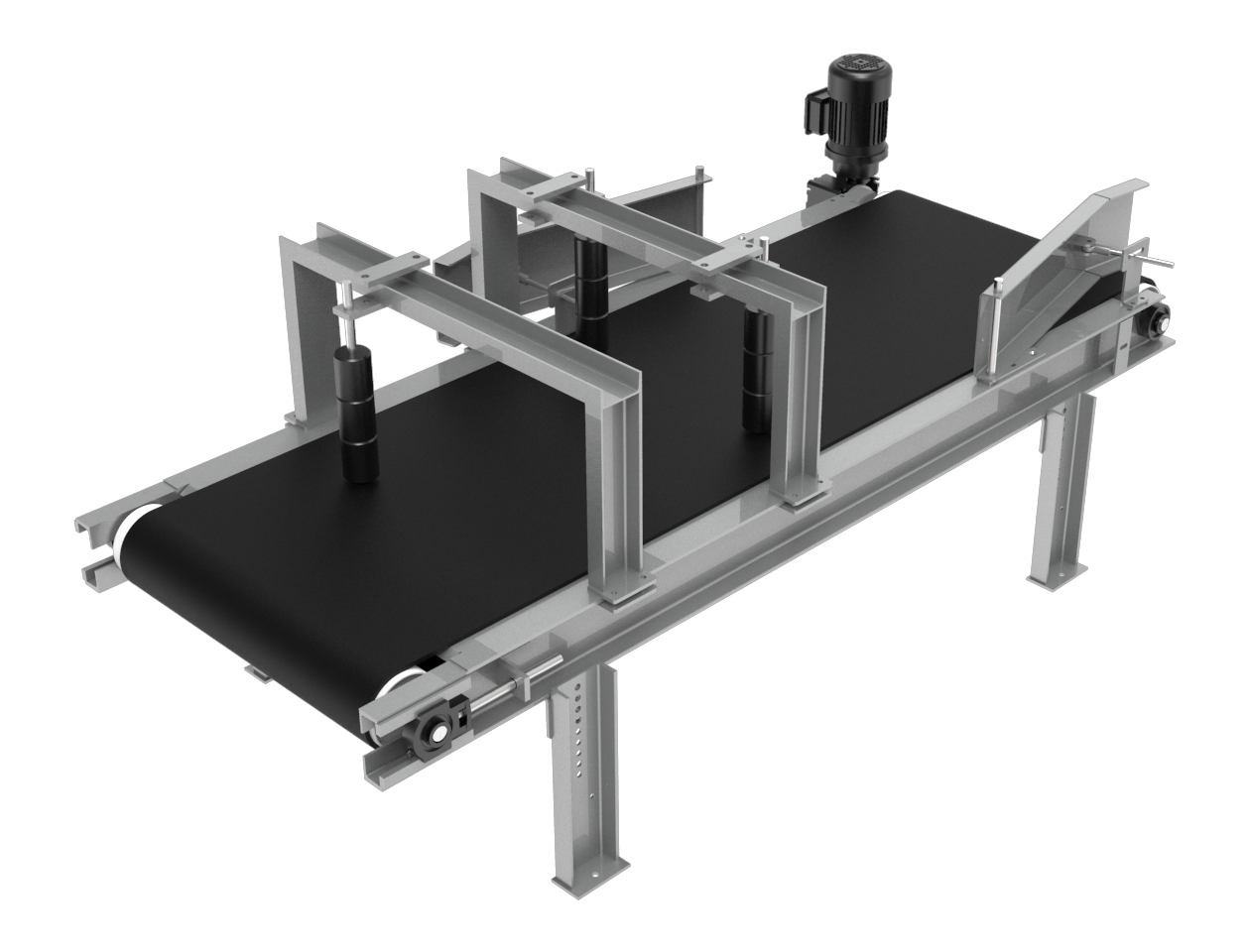

304 Series Incline Bag Flattener Conveyors remove excess air from bags improving appearance and stability. Bag thickness and shaping is easy to manage. The 304 has a 24” wide belt and comes in frame lengths up to 16’.

(220/440V / 3 Ph / 60 Cycle Electrical Standard)

305 Series Bag Turner Conveyors lay down open mouth bags as they are fed upright from a bag closing conveyor. The 305 Series comes with a 24” wide belt in frame lengths of 6’ and 8’.

(220/440V / 3 Ph / 60 Cycle Electrical Standard)

The 306 Series Bag Kicker Conveyor facilitates the 90 degree turn and transfer of filled, closed open mouth bags downstream for palletizing. 306 series conveyors mount to our 307 series closing model.

(115V / 1 Ph / 60 Cycle Electrical Standard; 80 PSI @ 1 CFM per Cycle)

The 307 Series Bag Closing Conveyor receives and presents open mouth bags to various closing systems. It comes with a 12” wide belt in frame lengths of 8’, 10’, 12’, and 14’.

(220/440V / 3 Ph / 60 Cycle Electrical Standard)

Our 308 Series Conveyor has a two-belt system to carry bags upright to a closing head. The stabilizing back rail and belt height are both adjustable and the conveyor comes in lengths up to 12 feet.

(220/440V / 3 Ph / 60 Cycle Electrical Standard)

310 Series Bag Discharge Conveyors receive and index filled valve bags to a bag palletizing system. They’re available in 30” & 36” belt widths in frame lengths of 8’, 10’ & 12’.

(220/440V / 3 Ph / 60 Cycle Electrical Standard)

The 314 Powered Curve Belt Conveyor is a motorized, 90-degree turn belt designed to integrate with bagging systems. It can alter the direction of a conveying line without changing the orientation of the bags.

(220/440V / 3 Ph / 60 Cycle Electrical Standard)

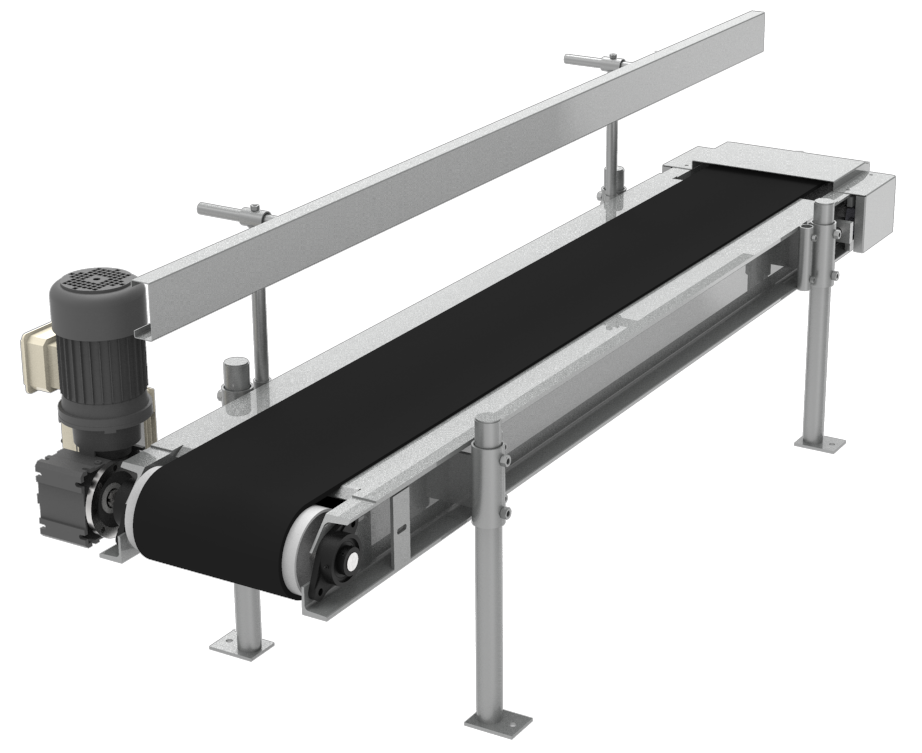

Model 315 is a conveyorized in-line printing system for labeling bags with lot and date codes, and other information. The system includes a 10′ by 24″ heavy duty slip top belt conveyor, bag straightening guides, and high resolution inkjet printer.

316 Series Gravity Roller Accumulation Conveyors collect filled bags for safe and ergonomic palletizing. They’re available in 24” frame widths with frame lengths of 3’ to 10’.

The 318 Bag Reject Conveyor system has a guide belt and air-operated pusher. It releases rejected bags onto a roller conveyor.

(220/440V / 1 Ph / 60 Cycle Electrical Standard; 80 PSI @ 1 CFM per Cycle)

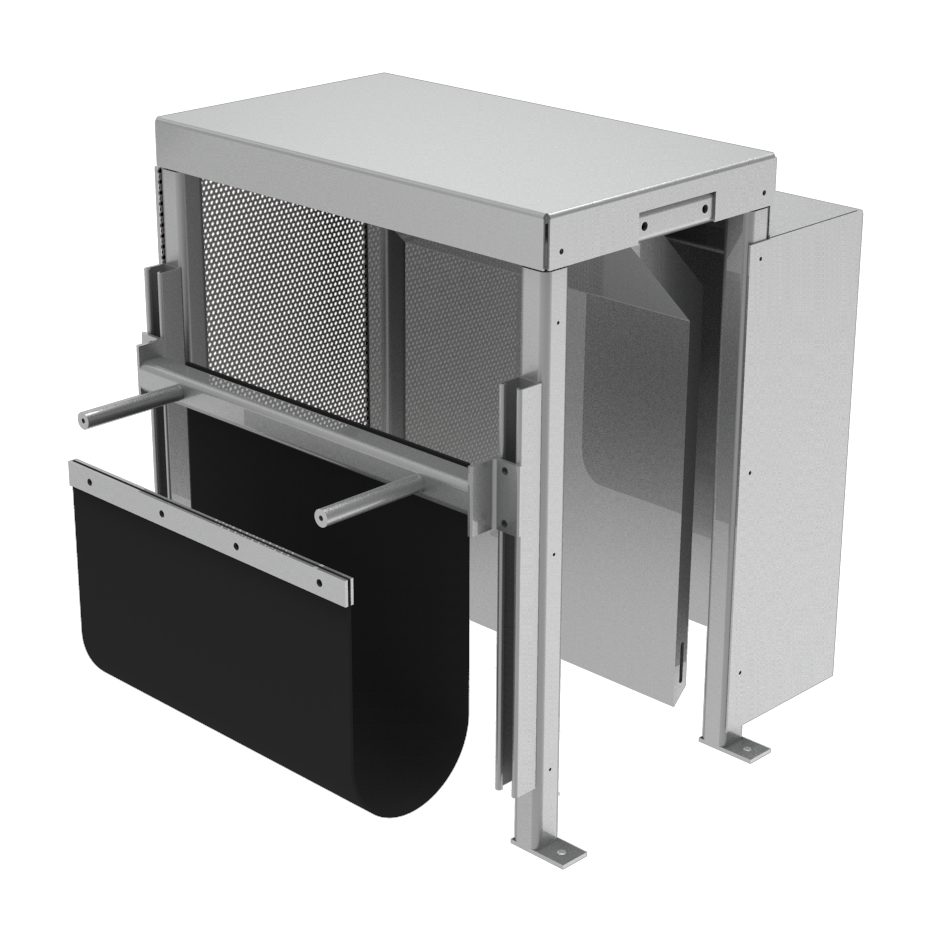

CBE metal detectors support packaging lines by identifying ferrous or nonferrous (including stainless steel) contaminates. These machines fit into our larger conveying systems which also include pacing, check weight, and bag reject equipment.

Our heavy-duty, in-line bag checkweigher with controller verifys the weight compliance of filled bags. It does so in motion as they move from the filling to palletizing station.

REQUEST A QUOTE!

What is an Industrial Bag Handling Conveyor System?

An industrial bag conveyor system is machinery which moves packages, products, supplies, parts, and equipment for production, shipping, or relocation. The type of bag handling system deployed in a production environment depends on a number of variables. These include bag weight and dimensions and what it will take to move the product or material.

Why Use Automated Bag Conveyors?

Automated bag conveyors are considered the industry standard to increase productivity and convenience in a bagging production line. They load and unload bags, move them between different heights, and send them anywhere all with full speed control. This level of flexibility greatly reduces the risk of breakage or handling problems. All CBE bag handling conveyors are built with rugged, powder-coated, 6” structural c-channel steel frames. They are designed and constructed for the most demanding industrial environments.

We Support Unique Industry Needs for Bag

Conveyor Systems

From mining to agriculture and beyond, different types of industries require uniquely configured bag conveyor systems. To meet these needs, we work closely with customers to fully understand their production environments and the materials they produce and ship. This allows us to design conveyor systems that fit them perfectly.

Mining

Automotive

Agriculture

Food & Drink

Warehousing

Logistics

Questions About Bag Handling Conveyors?

Every business has unique requirements for bag handling conveyor systems. We can help determine the best design and equipment for your specific needs. Please contact a Choice Bagging professional today for more information and to get answers to your questions.

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed