Selecting the right packaging equipment is a critical decision where performance and reliability are paramount. Inaccurate weights lead to lost profits, slow machinery creates production bottlenecks, and the wrong system can compromise workplace safety. Making a significant capital investment in a new bag filling machine can feel daunting, especially when every detail impacts your operational efficiency and bottom line.

This is why we created The Ultimate Buyer’s Guide for 2026. We are here to provide the clarity you need to move forward with confidence. This guide breaks down everything you need to know-from matching machine types to your specific product, to identifying the features that guarantee consistent accuracy and durability. Our goal is to empower you to choose a high-quality solution that not only solves today’s challenges but also serves as a profitable, long-term asset for your business.

Key Takeaways

-

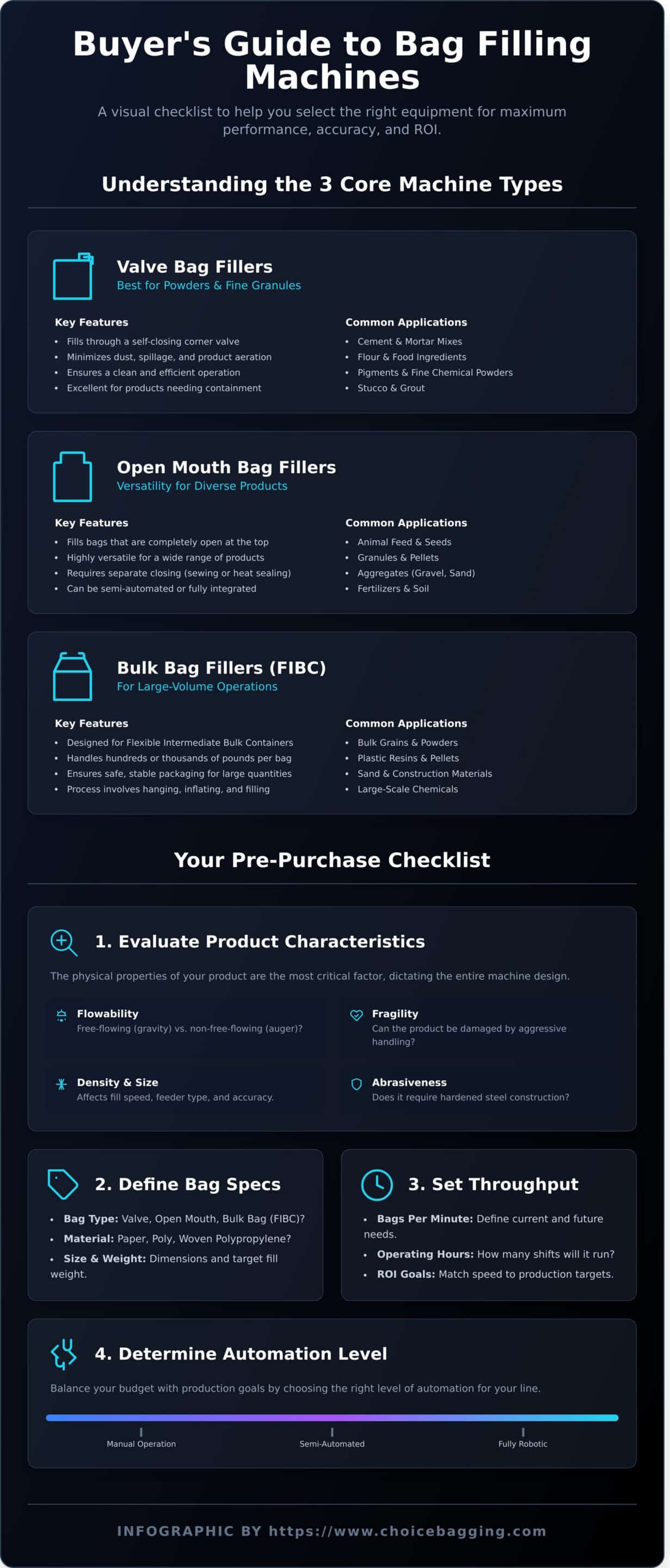

Understand the three main categories of industrial baggers to correctly match the equipment to your specific dry solid product.

-

Use our buyer’s checklist to evaluate critical factors like product characteristics, bag specifications, and required throughput for maximum ROI.

-

Determine the right level of automation for your operation, from semi-automated systems to fully robotic lines, to balance budget with production goals.

-

Learn how to prevent the most common operational issues to ensure your bag filling machine delivers consistent performance and reliability.

Table of Contents

-

Key Factors to Consider Before Choosing Your Bagging Equipment

-

Automation Levels: From Manual Operation to Fully Robotic Lines

Understanding the Core Types of Bag Filling Machines

Selecting the right bag filling machine is a critical decision that directly impacts your operational efficiency. The ideal system depends entirely on two key factors: the physical characteristics of your product and the style of bag you intend to fill. While there are many types of bag filling machines, industrial systems for dry solids generally fall into three primary categories. Each type utilizes a distinct filling mechanism, a choice that fundamentally affects filling speed, weight accuracy, and dust control within your facility.

To visualize how these systems operate, the following video provides a clear overview of an automated bagging process:

Valve Bag Fillers: For Powders and Fine Granules

Valve bag fillers are engineered for bags equipped with a self-closing opening, or valve, on the corner. This design is exceptionally effective for packaging fine powders and granules that are prone to creating dust. By filling through the small valve, product aeration and spillage are minimized, ensuring a clean and efficient operation. Common applications include cement, flour, pigments, and fine chemical powders. The primary sub-types include:

-

Air Packers: Use air pressure to fluidize and convey material into the bag.

-

Impeller Packers: Use a bladed impeller to propel material into the bag.

-

Auger Fillers: Use a screw-type auger for precise, volumetric filling.

These systems offer unmatched performance for specific product types. Explore our Valve Bag Fillers to find a reliable solution for your powder filling needs.

Open Mouth Bag Fillers: Versatility for Diverse Products

As the name suggests, open mouth bag fillers are designed for bags that are completely open at the top, such as pillow-style or gusseted bags. Their key advantage is versatility, making them suitable for a wide range of free-flowing products like granules, pellets, seeds, animal feed, and aggregates. After filling, these bags require a separate closing system, typically a high-speed sewing machine or a heat sealer. This type of bagging machine can be configured for manual placement or integrated into a fully automated line for maximum throughput. View our Open Mouth Bagging Machines for adaptable and high-performance options.

Bulk Bag Fillers (FIBC): For Large-Volume Operations

For high-volume applications, Bulk Bag Fillers provide the necessary scale and efficiency. These systems are built to handle Flexible Intermediate Bulk Containers (FIBCs), also known as super sacks or bulk bags, which can hold hundreds or even thousands of pounds of product. The process involves securely hanging the bag from integrated hooks, inflating it for proper shaping, and then filling it to a precise weight. Bulk bag fillers are the industry standard for materials like sand, grains, plastic resins, and bulk chemicals, ensuring safe and stable packaging for large quantities.

Key Factors to Consider Before Choosing Your Bagging Equipment

Selecting the right bag filling machine is a critical investment in your operational efficiency. To ensure the highest return, it’s essential to match the machine precisely to your application. This checklist is designed to help you define your requirements, not just for today, but for your future production goals. A thorough evaluation of these factors will ensure you invest in a solution built for long-term performance and reliability.

Product Characteristics: The Most Critical Factor

The physical properties of your product will dictate the core design of your bag filling machine. Mismatches here can lead to inaccurate fills, product damage, and operational downtime. Before proceeding, carefully define:

-

Flowability: Does your product flow freely like sand (gravity-fed), or does it require mechanical assistance, like flour (auger-fed)?

-

Density & Particle Size: These properties directly affect filling speed, the type of feeder needed, and the overall design of the product flow path.

-

Abrasiveness & Corrosiveness: Harsh materials may require specialized materials of construction, such as stainless steel, to ensure equipment longevity.

-

Fragility: Delicate products like seeds or some pelleted materials can be damaged by aggressive augers; a gentler filling method may be necessary.

Bag Specifications: Type, Size, and Material

Your choice of bag is the next key piece of the puzzle. The machine must be engineered to handle your specific bag type to ensure consistent and reliable sealing and handling. Key specifications include:

-

Bag Type: Are you using valve bags, open-mouth bags, or bulk bags (FIBCs)?

-

Bag Material: The material-whether paper, polyethylene (poly), or woven polypropylene-determines the required sealing or sewing technology.

-

Weight Requirements: Clearly define the target fill weight for each bag, as this is a fundamental parameter for machine selection and calibration.

Production Goals: Speed and Accuracy

Your operational targets for output and precision will determine the level of automation and the weighing technology required. While maximizing throughput is a common goal, it must be balanced with weighing accuracy and, most importantly, operator safety. Every high-performance bagging system must be engineered to meet or exceed established machine safety standards to protect your team and ensure compliance. Consider the following:

-

Required Throughput: How many bags per minute or hour do you need to fill to meet demand?

-

Weighing Accuracy: What level of precision is required (+/- %)? This will help determine if a gross weighing or more precise net weighing system is the right fit for your operation.

Defining these variables is the first step toward a successful equipment purchase. As your partner in this process, we encourage you to consult with our experts. We can help you navigate these factors to configure a solution that delivers unmatched performance for years to come.

Automation Levels: From Manual Operation to Fully Robotic Lines

Selecting the right level of automation for your bag filling machine is a critical decision that directly impacts your operational efficiency and return on investment. Automation is not an all-or-nothing proposition; it exists on a spectrum. The ideal solution depends on your specific production goals, labor availability, and budget. By integrating the appropriate level of automation, you can significantly reduce labor costs, improve fill accuracy, and ensure consistent, repeatable performance. Importantly, your bagging line can be designed for future growth, allowing you to upgrade with more automation as your throughput needs increase.

Manual and Semi-Automatic Systems

For operations with lower speed requirements, frequent product changeovers, or budget constraints, manual and semi-automatic systems offer a dependable and flexible solution. In a purely manual setup, an operator places each bag, initiates the fill cycle, and removes the filled bag. A semi-automatic bag filling machine enhances this process by adding features like automated weighing or pneumatic bag clamps, which improve accuracy and reduce operator fatigue. These systems are valued for their simplicity, reliability, and adaptability to various bag sizes and materials.

Fully Automatic Bagging Systems

When maximum throughput and minimal labor are the primary objectives, a fully automatic bagging system delivers unmatched performance. These integrated lines handle every step of the process without human intervention: from automatically placing empty bags onto the spout to filling, sealing, and conveying them downstream. As modern trends in automation in packaging continue to drive further innovation, these systems provide the highest levels of speed, consistency, and safety. The line culminates with automated stacking for shipment. Learn about Robotic Palletizing Systems that complete this powerful, end-to-end solution.

Determining the most cost-effective and productive automation level is key to a successful project. Our experienced team is here to partner with you, analyzing your needs to recommend a system built for lasting performance. Contact us today for a comprehensive consultation.

Common Bag Filling Problems and How to Solve Them

With decades of experience in the bagging industry, we’ve seen every potential issue arise. The good news is that most operational problems are preventable with the right equipment and proper maintenance. Understanding these common challenges is the first step in selecting a reliable bag filling machine that will deliver consistent performance. This knowledge helps you ask the right questions and invest confidently in a system built for durability and efficiency.

Challenge 1: Inaccurate Bag Weights

Giving away product with every bag directly impacts your bottom line. Inaccurate weights are often caused by inconsistent product flow, improper machine calibration, or excessive vibration from surrounding equipment. To ensure precision and protect your profits, we recommend focusing on these key areas:

-

Using the Correct Feeder: Match the feeder type (such as a screw, belt, or gravity feeder) to your product’s specific characteristics to ensure a consistent material feed.

-

Implementing Regular Calibration: A consistent schedule of calibration checks with certified weights guarantees your machine’s scale system remains accurate over time.

-

Ensuring a Solid Foundation: Your machine must be installed on a solid, vibration-free surface to protect sensitive load cells from interference.

For applications demanding the highest precision, net weigh fillers are engineered to provide superior accuracy over gross weigh systems.

Challenge 2: Excessive Dust and Product Spillage

A clean operation is a safe and profitable one. Dust and spillage are typically caused by a poor connection between the bag and the fill spout, an excessively high fill velocity, or a lack of dust control. A robust bag filling machine should offer proven solutions like inflatable spouts for a tight seal, dust-tight enclosures, and integrated dust collection ports. Systems like valve bag fillers are also inherently designed to minimize dust. Investing in these features protects your employees, reduces product waste, and maintains a safer work environment.

Challenge 3: Slow Production and Bottlenecks

Your bagging line should be an asset, not a bottleneck. Slowdowns often occur when a machine is not properly sized for the required throughput or when manual bag changeovers are inefficient. The solution lies in selecting a machine rated for your target speed from the start. For higher-speed operations, consider adding automated bag placers to maintain a consistent pace. Furthermore, proper operator training is critical to maximizing the efficiency of any system.

If you are experiencing persistent performance issues with your current setup, our expert field service team can help diagnose and resolve them.

Invest with Confidence: Your Partner in Packaging Performance

Selecting the right equipment is a critical decision that directly impacts your operational efficiency, product integrity, and bottom line. As this guide has detailed, a successful investment hinges on a clear understanding of machine types, a thorough evaluation of your production goals, and choosing the appropriate level of automation. Making an informed choice from the start is the key to seamless integration and avoiding costly, common bagging problems.

You don’t have to navigate this complex decision alone. Since 1978, Choice Bagging Equipment has built a reputation as more than just a manufacturer-we are your dedicated partner in performance. We engineer and build every reliable, high-performance bag filling machine here in the USA, ensuring you receive durable equipment backed by an expert support team committed to your long-term success.

Ready to move forward with clarity and confidence? Take the guesswork out of your investment and let our expertise guide you. Find the perfect machine for your needs with our Bagger Professor tool. Invest in a partnership that delivers reliability and performance for decades to come.

Frequently Asked Questions

How much does an industrial bag filling machine cost?

The cost of an industrial bag filling machine is determined by your specific operational requirements, including filler type, speed, and level of automation. A simple, manually operated system will have a different investment level than a fully automated line. We partner with you to engineer a high-performance solution that provides maximum value and a strong return on investment. Contact us for a detailed quote tailored to your exact needs.

What is the difference between a gross weigh and a net weigh filler?

A gross weigh filler weighs the product directly as it enters the bag, making it a compact and cost-effective solution. In contrast, a net weigh filler pre-weighs the product in a separate weigh hopper before discharging it into the bag. This two-step process generally delivers higher accuracy and faster fill rates, making it ideal for high-volume production lines where precision and performance are critical components of your operation.

What kind of maintenance does a bagging machine require?

Our bagging machines are engineered for durability and unmatched reliability, featuring minimal moving parts to reduce wear. Routine maintenance typically involves simple procedures like regular cleaning to prevent product buildup, lubrication of key components, and inspection of wear parts. This straightforward preventative care ensures decades of consistent, high-efficiency performance from your equipment, protecting your investment and minimizing operational downtime.

How do I know if I need an auger, impeller, or gravity filler?

The correct filler technology depends entirely on your product’s flow characteristics. Auger fillers provide precise control for non-free-flowing powders like flour. Impeller fillers are designed for aeratable powders such as cement and stucco. For free-flowing, granular materials like seeds, grains, or plastic pellets, a gravity filler offers a simple, reliable, and efficient solution. Our experts will help you identify the optimal technology for your specific application.

Can one machine handle different products and bag sizes?

Yes, a single bag filling machine can be engineered for exceptional versatility. By incorporating features like adjustable bag supports and quick-change spouts, our systems can efficiently handle a range of bag sizes and types. For different products, some models may require specific change parts to ensure optimal accuracy and performance. We design our equipment to be adaptable, providing a flexible and durable solution that grows with your business needs.

What is the typical lead time for a new bag filling machine?

Lead times vary based on the complexity of the machine and our current production schedule. Standard, pre-engineered models often have shorter lead times than fully customized or integrated systems. From the moment you place an order, we provide clear communication and a projected timeline. Our commitment is to manage the process with efficiency and deliver your high-quality, American-made equipment as promptly as possible.

Recent Comments