Slow production lines, broken stitches, and costly product spills are more than just daily frustrations-they are direct threats to your operational efficiency and bottom line. Choosing the right bag stitching machine is the critical step toward eliminating these bottlenecks, but the path forward is often unclear. With options ranging from portable handheld stitchers to fully integrated industrial sewing heads, selecting the wrong equipment can lead to integration headaches and unexpected downtime, jeopardizing your production targets.

This comprehensive guide delivers the clarity you need to invest confidently. We will break down the critical differences between portable and automated systems, providing the expert knowledge to evaluate performance, reliability, and maintenance requirements. Our goal is to equip you to select the most efficient and dependable machine for your production line, ensuring you can increase throughput, reduce labor costs, and achieve a secure, professional seal on every single bag.

Key Takeaways

-

Distinguish between portable and industrial systems to confidently select a machine engineered for your specific production demands.

-

Identify the core mechanical components that define a high-performance, durable bag stitching machine built for continuous operation.

-

Select the optimal stitch and thread combination based on your bag material to guarantee maximum closure security and integrity.

-

Understand how proper system integration and maintenance are critical for maximizing production uptime and operational efficiency.

Table of Contents

-

What is a Bag Stitching Machine? Portable vs. Industrial Systems

-

Anatomy of an Industrial Bag Sewing Head: Built for Durability

-

Choosing the Right Stitch and Thread for Maximum Bag Security

What is a Bag Stitching Machine? Portable vs. Industrial Systems

A bag stitching machine is a specialized piece of equipment designed for one critical purpose: closing open-mouth bags with a durable, secure sewn seam. Functioning as a heavy-duty industrial sewing machine, it ensures that products-from agricultural feed to construction materials-are safely contained for transport and sale. The market offers two primary categories of these machines: handheld portable stitchers and fixed industrial sewing heads. Choosing the right system is a crucial decision that directly impacts production speed, operational reliability, and long-term labor costs.

To see a common portable model in action, watch this brief video demonstration:

Understanding the fundamental differences between these systems is key to selecting equipment that aligns with your operational goals. The following table provides a clear comparison of their core attributes.

| Feature | Portable Stitcher | Industrial Sewing Head |

|---|---|---|

| Speed | Low (Operator Dependent) | High & Consistent |

| Volume | Low to Moderate | High to Very High |

| Initial Cost | Low | High (System Investment) |

| Maintenance | Basic / Frequent Oiling | Scheduled / Robust PM |

Handheld Portable Stitchers: For Low-Volume Needs

Portable stitchers are the go-to solution for farms, small businesses, and field repairs where mobility is essential. These corded electric or battery-powered devices offer flexibility but come with limitations. Their speed is entirely dependent on the operator, which can lead to slower throughput and inconsistent stitch quality. While excellent for low-volume applications or as a backup, they are not engineered for the demands of a continuous production environment.

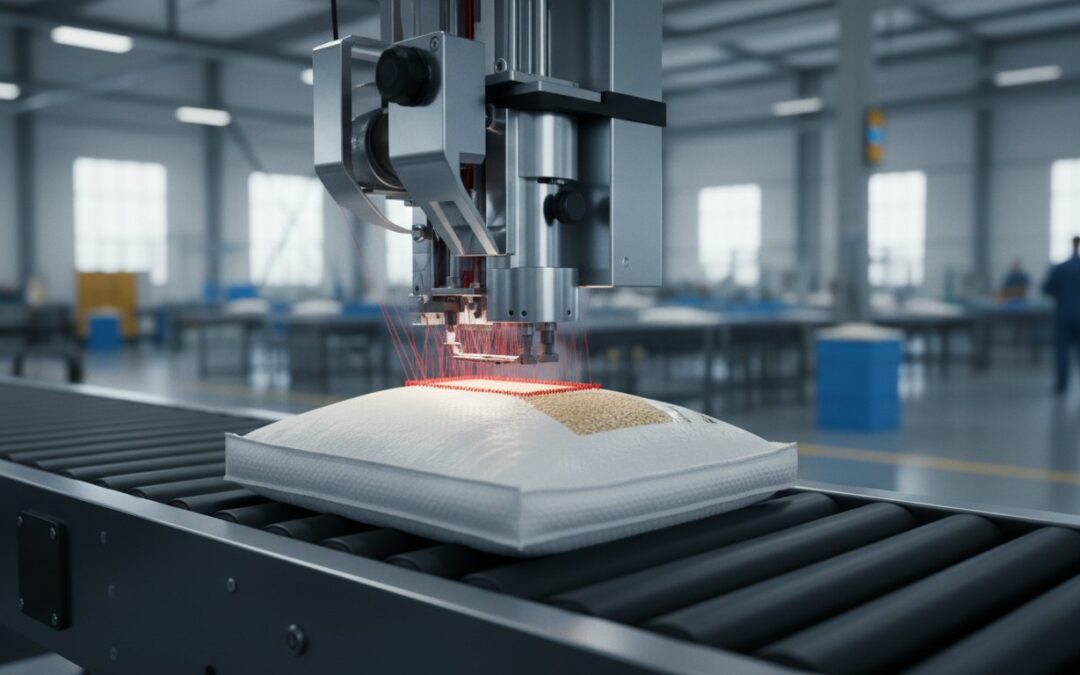

Fixed Automated Sewing Heads: The Industrial Standard

For high-volume bagging operations, a fixed automated sewing head is the industry standard for performance and reliability. These powerful machines are mounted on pedestals and integrated directly into a conveyor line, delivering high-speed, perfectly consistent seams with minimal operator intervention. This automation significantly reduces labor costs and eliminates production bottlenecks. A high-quality sewing head is the core component of dependable open mouth bagging systems, built to withstand the rigors of demanding industrial environments.

Anatomy of an Industrial Bag Sewing Head: Built for Durability

Unlike standard sewing machines, an industrial bag sewing head is engineered for one purpose: continuous, high-speed operation in demanding production environments. These machines are the workhorses of any packaging line, designed with robust components and high-quality materials to deliver unmatched reliability and performance. Understanding this construction is the first step in effective maintenance, as it highlights the importance of each part in preventing costly downtime. The robust design also contributes to a safer work environment, a principle supported by resources like OSHA ergonomic solutions for industrial sewing stations.

Many high-performance models feature self-lubricating systems, where a pressurized oil bath continuously coats critical moving parts. This essential feature drastically reduces wear and tear, extending the machine’s operational life and minimizing the need for manual lubrication.

The Drive System: Power and Precision

The heart of the bag stitching machine is its drive system, typically consisting of a powerful electric motor and a pulley mechanism. This system provides the necessary torque to sew through thick, multi-wall bags without hesitation. Crucially, variable speed control allows the sewing head to be precisely synchronized with the conveyor speed, ensuring consistent stitch quality and preventing bag damage. A clutch mechanism enables instantaneous starting and stopping, giving operators complete control over the sewing cycle.

Stitch Formation Components: Needle, Looper, and Feed Dogs

The perfect stitch is a result of three components working in flawless harmony. Each part is precision-machined for durability and consistent performance:

-

Needle: The needle’s primary job is to cleanly pierce the bag material, carrying the top thread through to the other side.

-

Looper: Working in tandem with the needle, the looper moves in a precise pattern to catch the needle thread and form a secure, single-thread chain stitch.

-

Feed Dogs: These toothed mechanisms grip the bag from below and pull it through the sewing head at a constant rate, ensuring every stitch is uniform in length.

Essential Features: Thread Cutters and Infeed Systems

To maximize efficiency, most industrial sewing heads incorporate automated features. Thread cutters, such as guillotine-style or rotary knife cutters, automatically sever the thread chain after a bag is closed, creating a clean finish and preparing the machine for the next bag. Paired with a dedicated infeed system that guides the bag top smoothly into the sewing area, these features are crucial for creating fully automated bag sewing machine systems that deliver high throughput with minimal operator intervention.

Choosing the Right Stitch and Thread for Maximum Bag Security

The performance of your bag stitching machine depends heavily on the quality and type of closure you select. The machine itself provides the power and precision, but the stitch type and thread are what guarantee product security from your facility to the end-user. The right choice is dictated by your product’s characteristics-such as particle size and weight-and the bag material you use.

A key factor in seam strength is Stitches Per Inch (SPI). A higher SPI creates a tighter, more secure closure, reducing the risk of product loss. A basic sewn closure might suffice for some applications, but a more secure, reinforced closure is essential for valuable, heavy, or fine-powdered products.

Stitch Types: Single-Thread vs. Two-Thread Closures

The two most common stitch types offer different levels of security:

-

Type 101 Single-Thread Chain Stitch: This is a simple, economical stitch that is easy for the end-user to open. It is best suited for lighter products and situations where high-level security is not the primary concern.

-

Type 401 Two-Thread Double-Locked Stitch: This stitch provides superior strength and integrity. It uses two threads that interlock, preventing the seam from unraveling if one thread breaks. It is the standard for heavier bags or products that undergo rough handling and shipping.

Adding Security: Sewn-Over-Tape (Tape-Over-Stitch)

For maximum product containment, especially for fine powders, a sewn-over-tape closure is the premium solution. This method involves folding a crepe paper tape over the top of the bag and stitching through both the tape and the bag material. This technique offers unmatched benefits, including preventing sifting, adding a moisture-resistant barrier, and significantly reinforcing the closure. It is ideal for high-value products like flour, spices, and fine minerals.

Selecting the Right Sewing Thread

The thread is the backbone of a reliable seam. Most industrial applications use polyester thread for its high tensile strength, resistance to abrasion, and low moisture absorption. Thread strength is measured in denier; a higher denier indicates a thicker, stronger thread suitable for heavy-duty bags. For bags stored outdoors, specifying a UV-resistant thread is critical to prevent degradation from sun exposure. A well-maintained bag stitching machine can handle various thread weights to match your specific operational needs.

Ensuring you have the right components for your application is key to operational efficiency. If you need expert guidance, contact our team to discuss your needs. We are more than a supplier; we are your partner in packaging.

Integration, Maintenance, and Maximizing Production Uptime

A high-performance bag stitching machine is a critical component, but its true value is realized when it operates flawlessly within your larger packaging line. Achieving maximum production uptime and consistent quality depends on proper system integration and a disciplined approach to preventative maintenance. By viewing the sewing head not as a standalone unit but as part of an interconnected system, you can proactively manage its performance and extend its operational life.

Seamless integration with bag fillers and conveyors is the foundation of an efficient and automated packaging process. This synergy ensures that each step, from filling to closing, is perfectly synchronized for optimal throughput and reliability.

Integrating with Conveyors and Bag Fillers

For smooth operation, the sewing head must be synchronized with the conveyor speed. This ensures each bag passes through the sewing area at the correct velocity for a strong, uniform stitch. V-trough or flat belt bag handling conveyors are engineered to present the bag to the sewing head consistently. To further enhance efficiency, photoelectric sensors can automate the start/stop sequence, activating the machine only when a bag is in position, reducing wear and operator error.

Essential Preventative Maintenance Checklist

A routine maintenance schedule is the most effective strategy for preventing unexpected downtime. Investing a few minutes each day can save hours in lost production. We recommend a tiered approach to keep your equipment in peak condition.

-

Daily Tasks: Clear away lint and dust from the needle area, loopers, and feed dogs. Visually inspect the thread path for obstructions and check for any loose components.

-

Weekly Tasks: For models that are not self-lubricating, apply oil to all specified moving parts according to the manufacturer’s manual to ensure smooth, low-friction operation.

-

Monthly/Quarterly Tasks: Carefully inspect high-wear parts like needles, loopers, and feed dogs. Replace any components that appear dull, bent, or damaged to maintain stitch quality.

Troubleshooting Common Issues

Even with diligent maintenance, minor operational issues can arise. Addressing them quickly is key to minimizing disruption. Here are solutions to the most common challenges:

-

Skipped Stitches: This is often caused by a bent or incorrectly installed needle, improper threading, or timing issues. Always start by installing a new, correct-size needle.

-

Broken Thread: Check the entire thread path for sharp edges or burrs that could be snagging the thread. Also, verify that the tension settings are correct and that you are using high-quality, fresh thread.

-

Uneven Stitching: Irregular stitches are typically related to incorrect presser foot pressure or worn feed dogs that are not gripping the bag material properly.

For more complex mechanical or electrical problems, attempting a repair without proper training can cause further damage. In these situations, rely on expert field service and professional support to diagnose and resolve the issue correctly. At Choice Bagging Equipment, we are not just a supplier; we are your partner in production. Contact us today for reliable equipment and support built to last.

Partner with the Experts for Unmatched Bag Closing Reliability

Selecting the right bag closing system is a critical decision for your operational efficiency. As we’ve explored, the performance of your line depends not just on choosing between portable and industrial systems, but on the durability of the sewing head, the security of the stitch, and a commitment to proper maintenance. A well-integrated and reliable bag stitching machine is the final, crucial step in protecting your product and ensuring consistent throughput.

Investing in the right equipment means investing in a partnership. Since 1978, Choice Bagging Equipment has been manufacturing reliable bagging equipment, all Made in the USA for unmatched quality and durability. We don’t just sell machines; we provide expert integration and long-term partner support to ensure your success. Let our experience guide you to the perfect solution for your needs.

Ready to enhance your production line’s performance and reliability? Consult our experts to find the right bag sewing system for your line. Invest confidently and secure your operations for years to come.

Frequently Asked Questions

What is the difference between a bag sewing machine and a bag stitching machine?

In the industrial bagging industry, the terms "bag sewing machine" and "bag stitching machine" are used interchangeably to describe the same equipment. Both refer to a heavy-duty machine engineered for closing filled bags with a secure sewn stitch. While "sewing" might imply creating a garment, "stitching" is a common term for the specific, durable closure required for industrial bags. Ultimately, both terms describe the same reliable and efficient closing technology used in high-volume production environments.

How fast can an industrial bag stitching machine close bags?

The speed of an industrial bag stitching machine is a key performance metric, typically measured in feet per minute (FPM). High-performance models can operate at speeds ranging from 35 to 55 FPM, which translates to closing approximately 7 to 10 standard-width bags per minute. The final throughput depends on factors like conveyor speed, bag size, and the efficiency of the operator or automated system feeding the bags into the machine.

Can you use a bag stitching machine on multi-wall paper and poly-woven bags?

Yes, a key advantage of an industrial bag stitching machine is its versatility and power. These machines are engineered specifically to handle robust materials like multi-wall paper bags and poly-woven (polypropylene) bags. The strong needle and durable thread create a secure, sift-proof closure that maintains its integrity even with heavy or abrasive products. This makes stitching a dependable solution for a wide range of agricultural, chemical, and food-grade applications.

What’s better for closing bags: sewing or heat sealing?

The optimal choice between sewing and heat sealing depends entirely on your specific application, bag material, and product requirements. Sewing provides a strong, breathable, and easily opened closure, which is ideal for agricultural products and multi-wall paper bags. Heat sealing creates an airtight and moisture-proof seal, which is critical for food products or fine powders in plastic bags. We often consult with our partners to determine the most reliable and efficient solution for their unique production line.

How often do you need to replace the needle on an industrial sewing head?

For optimal performance and to prevent damage to your equipment, we recommend replacing the needle after every 8 to 10 hours of continuous operation. A more practical measure for many facilities is to replace it at the start of each shift. Signs of a dull or damaged needle include skipped stitches, frayed thread, or visible tearing of the bag material. Proactive replacement is a simple maintenance step that ensures consistent, high-quality closures and protects your investment.

What is the typical cost of an automated industrial bag sewing system?

The cost of a complete automated industrial bag sewing system is a significant investment in long-term efficiency and reliability. A typical system, including the sewing head, pedestal, power infeed, and conveyor, can range from $15,000 to $30,000 or more. The final price depends on the level of automation, conveyor length, specific components required for your product, and the degree of system integration. We provide detailed consultations to engineer a system that meets both your performance needs and budget.

Recent Comments