Navigating the world of industrial packaging can feel overwhelming. With technical terms like ‘impeller,’ ‘auger,’ and ‘gravity feed’ clouding the landscape, selecting the right bagging machine for your specific product can be a daunting task. You know automation is key to efficiency, but concerns about cost, ROI, and integration into your existing production line can lead to paralysis.

This critical decision shouldn’t be a source of uncertainty. It should be a strategic investment that unlocks greater productivity and profitability for your business. A well-chosen system ensures performance, reliability, and a seamless fit with your operational goals.

In this comprehensive manufacturer’s guide, we will demystify the selection process. Drawing on our experience since 1978, we will break down the primary categories of industrial baggers, help you identify the ideal technology for your materials, and provide the clear insights you need to invest confidently. Our goal is to empower you to create a more efficient and profitable packaging process, backed by the durability and support of a trusted, US-based partner.

Key Takeaways

-

Identify the three primary types of baggers to match the right technology to your specific product and bag requirements.

-

Follow a proven four-factor framework to analyze your operational goals, ensuring you select a system that delivers long-term performance.

-

Maximize your efficiency by learning how to integrate your bagging machine seamlessly with a complete packaging line.

-

Understand the critical difference between bagging and Form-Fill-Seal systems to confidently invest in equipment built for reliability.

Table of Contents

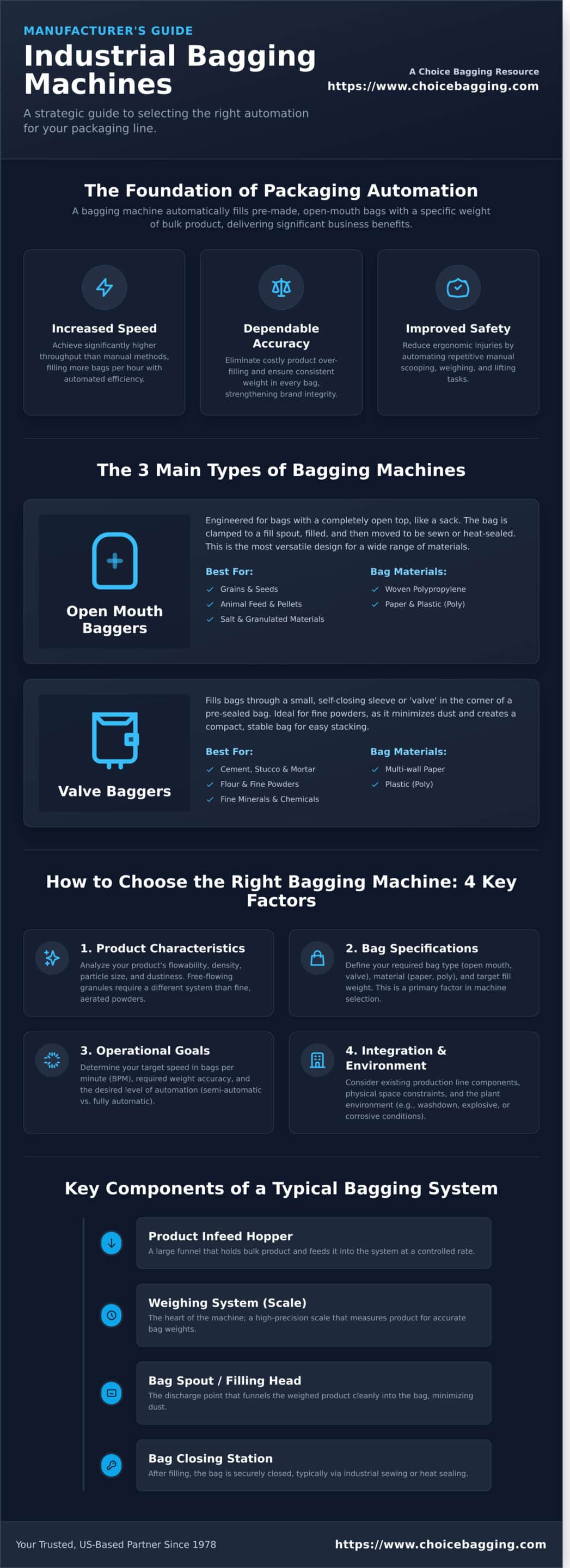

What is a Bagging Machine? The Foundation of Packaging Automation

A bagging machine is a specialized piece of equipment engineered to fill pre-made, open-mouth bags with a specific weight or volume of bulk product. This core function distinguishes it from Form-Fill-Seal (FFS) systems, which create, fill, and seal the bag from a continuous roll of film. As a crucial category of industrial Packaging machinery, these systems are designed to package products with unmatched reliability and efficiency.

To see a modern bagging system in operation, view the following demonstration:

The fundamental business benefits of integrating a bagging system are increased speed, accuracy, and consistency. Automation allows for significantly higher throughput than manual methods, filling more bags per hour with dependable precision. This accuracy eliminates costly product over-filling and ensures customers receive exactly what they paid for, while consistency in bag weight and appearance strengthens brand integrity.

Furthermore, automating the bagging process directly reduces labor costs and improves workplace safety. By replacing repetitive manual scooping, weighing, and lifting, these machines minimize the risk of ergonomic injuries for employees, creating a safer and more efficient operational environment.

From Manual Labor to Automated Efficiency

The evolution from manual bagging highlights the tangible value of automation. Manual scooping and weighing are slow, prone to inconsistency, and physically demanding. Semi-automatic systems offer a practical entry point, requiring an operator to place the bag on the spout while the machine manages the weighing and filling. For high-volume operations demanding maximum throughput and performance, fully automatic systems provide a complete, hands-off solution from bag placement to closing.

Key Components of a Typical Bagging System

While designs vary, most systems are built around four core components working in unison to ensure reliable performance:

-

Product Infeed Hopper: This large funnel holds the bulk product, feeding it into the system via a controlled flow gate to regulate material flow.

-

Weighing System (Scale): The heart of the machine, a high-precision scale measures the product to ensure every bag meets the target weight with minimal deviation.

-

Bag Spout or Filling Head: This is the discharge point where the weighed product is funneled cleanly into the waiting bag, designed to minimize dust and product loss.

-

Bag Closing Station: After filling, the bag moves to a station for secure closing, typically through industrial sewing or heat sealing.

The 3 Main Types of Bagging Machines: A Breakdown

Selecting the right bagging equipment is a critical engineering decision that directly impacts operational efficiency, product integrity, and profitability. The choice hinges on two primary factors: the product you are packaging and the type of bag you intend to use. Not every bagging machine is built for every application. To put it simply, think of the difference between an open-top sack for animal feed and a sealed cement bag with a small valve in the corner-each requires a fundamentally different filling technology.

Matching the machine to the specific application is essential for achieving optimal performance, accuracy, and reliability. With the global Bagging Machines Market projected for significant growth, making an informed equipment choice is more crucial than ever for maintaining a competitive edge. Understanding the three primary categories is the first step in engineering a successful packaging line.

Open Mouth Bagging Machines

As the name suggests, these machines are engineered for bags with a completely open top, similar to a pillowcase or a large sack. They are the ideal solution for packaging free-flowing, granular products. The bag is clamped to a fill spout, filled with a precise weight of material, and then typically transferred to be sealed by sewing or heat sealing. This versatile design is perfect for a wide range of materials.

- **Best for:** Grains, seeds, animal feed, pellets, salt, and other granulated materials.

- **Bag Materials:** Woven polypropylene, paper, and plastic (poly).

- See our range of reliable [Open Mouth Bagging Machines](https://www.choicebagging.com/open-mouth-bagging-machines/) for various applications.

Valve Bag Fillers

Valve bag fillers are designed for bags that feature a small, self-closing opening, or "valve," in the corner. Product is injected through this valve, and the internal pressure of the material automatically seals the opening once filled. This enclosed system is a superior choice for fine powders, as it drastically minimizes dust during the filling process. The result is a clean, safe work environment and a compact, squarely-stacked pallet.

- **Best for:** Cement, stucco, flour, fine minerals, pigments, and other powders.

- **Key Benefit:** Provides a clean, dust-free filling process and a solid, stable package.

- Explore our durable [Valve Bag Fillers](https://www.choicebagging.com/valve-bag-fillers/) built for demanding environments.

Bulk Bag (FIBC) Fillers

When operations require packaging materials on a massive scale, Bulk Bag Fillers are the definitive solution. These heavy-duty systems are engineered to fill Flexible Intermediate Bulk Containers (FIBCs), also known as super sacks or totes. They provide a stable, efficient method for handling enormous volumes, with integrated features for densifying material and ensuring accurate, repeatable weights for large-scale transport and storage.

- **Best for:** High-volume handling of sand, gravel, fertilizers, plastic resins, and bulk powders.

- **Capacity:** Designed for weights from 500 to 4000+ pounds.

- Learn about our heavy-duty [Bulk Bag Fillers](https://www.choicebagging.com/bulk-bag-fillers/) for high-volume needs.

How to Choose the Right Bagging Machine: 4 Key Factors

Selecting the right bagging machine is a critical capital investment that directly impacts your operational efficiency and profitability. A methodical analysis of your application prevents costly purchasing errors and ensures your equipment delivers reliable performance for years to come. To navigate this process with confidence, we recommend framing your requirements around four key pillars: your Product, your Bag, your Performance goals, and your desired level of Automation.

Consulting with an experienced equipment partner is the most effective way to ensure all variables are accounted for, leading to a solution engineered for your specific needs.

Factor 1: Your Product’s Characteristics

The physical properties of your product are the primary determinant of the filling technology required. An incorrect match between product and filler leads to inaccurate weights, product damage, and slow production rates. You must precisely define:

-

Flowability: Is your product free-flowing like seeds or pellets, sluggish like brown sugar, or a fine powder like flour? This dictates whether you need a gravity, auger, or vibratory feeder.

-

Bulk Density: The weight of your product per cubic foot (lbs/ft³) determines the size of the feeder, spout, and bag.

-

Other Properties: Consider if the material is abrasive, corrosive, fragile, or dusty. These characteristics influence the machine’s materials of construction (e.g., stainless steel) and the need for dust collection systems.

Factor 2: Your Bag Specifications

Your choice of packaging directly influences the design of the bag handling, filling, and closing components. The machine must be built to accommodate your specific bag, so have clear answers to the following:

-

Bag Type: Are you using open mouth bags, valve bags, or bulk bags (FIBCs)? Each type requires a completely different style of bagging machine.

-

Bag Material: Common materials include multi-wall paper, plastic (polyethylene), and woven polypropylene. This choice affects how the bag is sealed, whether by sewing, heat sealing, or gluing.

-

Bag Size & Weight: Define your target fill weight and the corresponding bag dimensions (length, width, and gusset).

Factor 3: Your Performance Requirements

Finally, you must clearly define your operational targets to ensure your equipment can meet demand. As market analysis from sources like Global Market Insights shows, the growing need for efficient packaging solutions makes this step more critical than ever. The targets you set will determine the overall scale and complexity of the investment.

-

Speed: How many bags per minute (BPM) or per hour must the system produce to meet your production goals?

-

Accuracy: What is the acceptable weight variance per bag (e.g., +/- 2 ounces)? Higher accuracy requirements often necessitate more sophisticated weighing technology.

-

Operating Environment: Will the machine operate in a clean room, a dusty plant, or a corrosive environment? This dictates the necessary NEMA rating for electronics and the machine’s overall construction.

Building a Complete Packaging Line: Beyond the Bagger

A high-performance bagging machine is the heart of any packaging operation, but its true efficiency is unlocked only when it is part of a seamlessly integrated system. Achieving maximum throughput, accuracy, and reliability requires a holistic approach that considers the entire production flow-from bulk material storage to the final stacked pallet. Viewing the process as a complete line, rather than a series of disconnected steps, is critical for long-term success. This is where working with a partner who understands the full engineering process provides undeniable value.

Upstream: Feeding the Machine

The packaging process begins long before your product reaches the bagger. Proper material handling is foundational. Bulk storage systems like silos or hoppers hold your product, while a network of conveyors reliably transports it to the packaging station. Crucially, feeders are used to regulate the product stream, ensuring a consistent and controlled flow into the bagging machine. This precise material delivery is essential for maintaining weighment accuracy and consistent cycle times.

Downstream: Closing, Conveying, and Palletizing

Once a bag is filled, the downstream process takes over to prepare it for shipment. This critical phase includes:

-

Bag Closing: Depending on the bag type and product, bags are securely sealed using industrial sewing machines or heat sealers for a durable, reliable closure.

-

Conveying: Filled bags are moved away from the operator station quickly and safely using specialized Bag Handling Conveyors, which are designed to keep the line moving without interruption.

-

Palletizing: The final step is stacking bags onto a pallet. For ultimate efficiency and labor savings, automated systems handle this repetitive task with precision. Automate your end-of-line with our Robotic Palletizing Systems to create consistent, stable, and perfectly stacked pallets every time.

Every component in a packaging line-from the infeed conveyor to the robotic palletizer-must work in unison. A bottleneck at any stage can compromise the performance of the entire system. By designing a complete, integrated solution, you ensure that your investment delivers the durability, efficiency, and return you expect. For guidance on designing a system built for performance, partner with an expert who understands every component.

Why Partner with Choice Bagging Equipment Since 1978

Selecting the right equipment for your production line is a critical decision that impacts your efficiency and profitability for years to come. At Choice Bagging Equipment, we understand that you are not just buying a machine; you are investing in a long-term solution. Since 1978, we have built our reputation on being more than a vendor-we are your dedicated partner, committed to delivering unmatched reliability and performance that you can depend on.

American-Made Quality and Durability

Our commitment to quality starts with our engineering and manufacturing process, based entirely in the USA. Every bagging machine we build is constructed from heavy-gauge steel and designed with minimal moving parts, ensuring decades of service with lower maintenance requirements. When you partner with us, you gain direct access to our engineering team and a comprehensive, US-based parts inventory, eliminating long waits and complex supply chains.

Unmatched Expertise and Support

With over 40 years of hands-on experience, we have solved some of the industry’s most complex bagging challenges. Our expertise extends beyond the factory floor. We provide expert Field Service for professional installation, operator training, and responsive repairs to keep your line running at peak performance. For those starting their search, our proprietary ‘Bagger Professor’ tool helps you quickly identify the ideal machine for your specific application.

Flexible Solutions for Every Budget

We believe high-performance equipment should be accessible. That’s why we provide a range of options to fit your financial and operational needs. Our inventory includes new, used, and fully refurbished equipment, all held to our rigorous quality standards.

-

Our Bagging Equipment Rental Program is the perfect solution for seasonal demands or short-term projects.

-

We offer a buyback program to help you seamlessly upgrade your existing systems as your business grows.

Invest confidently in a partner dedicated to your success. Explore our solutions and contact us today to discuss your project.

Make the Right Choice for Your Packaging Line

Choosing the right packaging equipment is a critical investment in your operational efficiency. As this guide has shown, a successful selection depends on understanding the different machine types available and carefully evaluating your specific product, speed requirements, and long-term goals. Remember, an effective packaging line is more than a single machine; it’s a fully integrated system designed for peak performance.

This is where partnering with a seasoned expert makes all the difference. As a trusted manufacturer since 1978, we provide more than just a bagging machine-we deliver a complete, high-performance solution. Our reliable equipment is proudly Made in the USA, engineered for decades of durability, and backed by expert integration and field support to ensure your success.

Ready to enhance your production with a system built for reliability? Contact our experts today for a personalized equipment consultation. We are committed to helping you build a more productive and profitable future.

Frequently Asked Questions About Bagging Machines

How much does an industrial bagging machine cost?

The investment for an industrial bagging machine varies based on several key factors, including the level of automation, required production speed, construction materials, and any custom engineering. A semi-automated system will differ in price from a fully integrated, high-speed line. We provide detailed consultations to engineer a solution that meets your specific performance requirements and budget, ensuring a high-value investment built for long-term reliability and efficiency.

What is the typical lead time for a new bagging machine?

Our standard lead times for new equipment typically range from 12 to 18 weeks after design approval. This period allows for meticulous engineering, high-quality fabrication of all components, assembly, and rigorous factory acceptance testing. We are committed to a transparent process and will provide a more precise timeline for your specific project, ensuring your new system is delivered ready for seamless integration and immediate performance.

What kind of maintenance does a bagging machine require?

Our machines are engineered for durability with minimal moving parts to reduce maintenance needs. A proactive preventative maintenance schedule is key to ensuring decades of reliable operation. This typically includes daily visual inspections, weekly lubrication of key components, and periodic checks of wear parts like belts and seals. Each machine is delivered with a comprehensive manual that clearly outlines all required maintenance procedures to maximize uptime and protect your investment.

Can one machine handle different products and bag sizes?

Yes, versatility is a core principle in our engineering. A single bagging machine can be designed to handle a range of product types and accommodate various bag sizes and weights. This flexibility is achieved through features like adjustable settings for fill volume, quick-change tooling for different bag dimensions, and user-friendly controls. We partner with you to understand your complete operational needs and configure a machine that maximizes your production efficiency.

How much floor space is needed to install a bagging system?

The required footprint depends entirely on the system’s configuration. A standalone bagger may only require 50-100 square feet, while a fully automated system with infeed conveyors, bag conditioning, and palletizing equipment can occupy 400 square feet or more. During our consultation process, we analyze your facility’s layout and provide detailed drawings to ensure the entire bagging system is integrated efficiently and safely into your available space.

Do you offer training for our operators?

Absolutely. We consider comprehensive operator training a critical component of every successful installation. Our factory-certified technicians provide thorough on-site training for your team, covering safe machine operation, product changeover procedures, routine maintenance tasks, and basic troubleshooting. We are your partner in performance, and our goal is to empower your staff to operate the equipment confidently and efficiently from day one.

Recent Comments