The search for the right equipment can feel overwhelming. When you’re evaluating dozens of packaging machine suppliers, you’re not just buying a machine; you’re making a critical investment in your production line’s future. With countless technical specifications to compare and a complex market of manufacturers and distributors, how can you be certain you’re choosing a partner who will deliver on their promises of reliability and performance?

This guide is designed to cut through the noise and provide a clear, practical framework for your decision. We will outline the essential criteria for vetting potential suppliers, from technical capabilities and build quality to the long-term value of their after-sales support. You’ll learn how to move beyond a simple vendor transaction to find a true partner committed to your operational success, ensuring your new equipment delivers maximum efficiency and uptime for years to come.

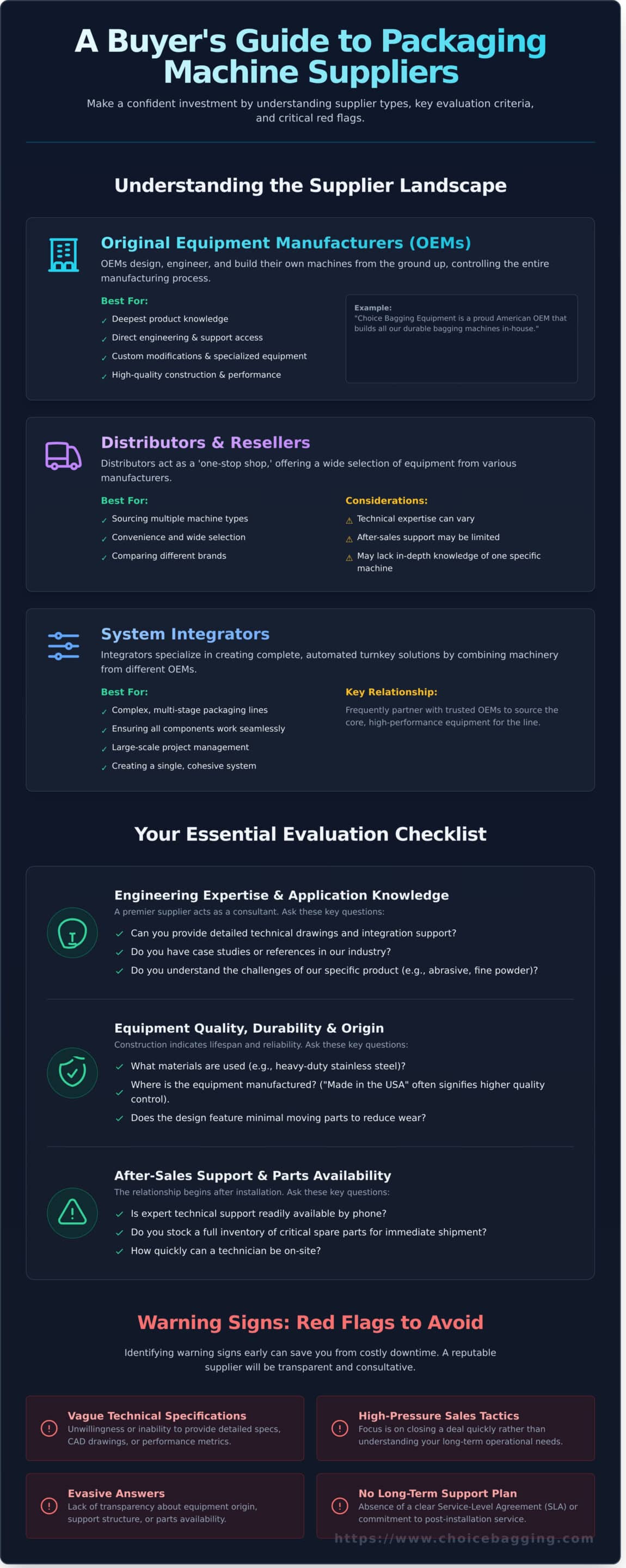

Understanding the Types of Packaging Machine Suppliers

Selecting the right partner from a field of diverse packaging machine suppliers is a critical business decision. The packaging industry is complex, and your choice of supplier directly impacts everything from initial cost and equipment reliability to long-term support and operational efficiency. Understanding the fundamental differences between the companies that manufacture, sell, or integrate equipment is the first step toward making a confident investment.

To visualize the type of equipment these suppliers provide, see this automatic packing machine in action:

Original Equipment Manufacturers (OEMs)

An Original Equipment Manufacturer (OEM) designs, engineers, and builds its own machines from the ground up. This provides you with the deepest product knowledge and direct access to engineering support. When an operation requires custom modifications or specialized equipment, an OEM is the most dependable partner. They control the entire manufacturing process, ensuring high-quality construction and performance. For example, Choice Bagging Equipment is a proud American OEM that builds all our durable bagging machines in-house.

Distributors and Resellers

Distributors act as a ‘one-stop shop,’ offering a wide selection of equipment from various manufacturers. This model can be convenient if you need to source multiple types of machines from different brands. However, their level of technical expertise and after-sale support can vary significantly. Because they represent many product lines, they may not possess the in-depth knowledge of a single piece of packaging machinery that an OEM can provide.

System Integrators

System integrators specialize in creating complete, automated turnkey solutions. They excel at combining machinery from different OEMs into a single, cohesive packaging line. If your project is complex and involves multiple stages—such as filling, sealing, and palletizing—an integrator has the project management expertise to ensure all components work together seamlessly. They frequently partner with trusted OEMs to source the core, high-performance equipment for the line.

Each of these supplier models serves a distinct purpose. Your business needs—whether for a single, reliable machine or a fully integrated, complex line—will determine which type of partner is the right fit. By identifying the right category of packaging machine suppliers from the start, you can streamline your search and focus on partners who have the specific expertise and capabilities to ensure your project’s success.

Key Criteria for Evaluating Any Packaging Machine Supplier

Selecting the right partner from a list of packaging machine suppliers goes far beyond comparing initial price quotes. A thorough evaluation is a critical investment in your operational future, preventing costly downtime and production bottlenecks down the line. To compare potential suppliers fairly, use a consistent checklist focused on long-term value and capability. Asking the right questions reveals a supplier’s true expertise, equipment quality, and commitment to support—the essential factors that separate a mere equipment vendor from a true production partner.

Engineering Expertise and Application Knowledge

A premier supplier acts as a consultant, not just a salesperson. They must demonstrate a deep understanding of your specific product’s challenges, whether it’s handling abrasive materials, managing fine powders, or ensuring accurate weights. Inquire if they can provide detailed technical drawings and integration support to ensure the machine fits seamlessly into your existing line. Ask for case studies or references within your industry, and look for suppliers recognized by leading organizations like PMMI, The Association for Packaging and Processing Technologies, which signifies a commitment to industry best practices.

Equipment Quality, Durability, and Origin

The physical construction of the equipment is a direct indicator of its lifespan and reliability. Ask about the materials used, such as heavy-duty stainless steel, and look for intelligent designs that feature minimal moving parts to reduce wear and maintenance needs. It is also important to ask where the equipment is manufactured; a “Made in the USA” label often signifies higher quality control and robust engineering. Durable machines like our valve bag fillers are built with these principles in mind, designed to deliver consistent performance for decades.

After-Sales Support and Parts Availability

Your relationship with a supplier truly begins after the installation is complete. A strong partner will offer a comprehensive Service-Level Agreement (SLA) that clearly outlines their commitment. Key questions to ask include:

- Is expert technical support readily available by phone?

- Do they stock a full inventory of critical spare parts for immediate shipment?

- How quickly can a technician be on-site?

Dependable field service is non-negotiable for minimizing production stoppages and protecting your investment.

Red Flags to Watch For When Sourcing Equipment

A new packaging machine is a significant capital investment that directly impacts your operational efficiency and profitability. Identifying warning signs early in the selection process can save your company from costly downtime and a frustrating partnership. A reputable supplier will be transparent, consultative, and focused on your long-term success. Conversely, high-pressure sales tactics and evasive answers often hide underlying issues with the equipment or the company’s ability to support it. Always trust your gut; if something feels off, it warrants a deeper investigation.

Vague Technical Specifications

A competent manufacturer knows their equipment inside and out. If a potential supplier is unwilling or unable to provide detailed technical specifications, CAD drawings, or clear performance metrics, consider it a major red flag. They should be able to confidently answer questions about cycles per minute, fill accuracy, and changeover times. Most importantly, they must be able to explain precisely how their machine will handle your specific product and integrate into your existing production line. Ambiguity here suggests a lack of expertise or a product that may not be right for you.

Lack of a Clear Support Structure

The relationship with your supplier shouldn’t end once the machine is installed. Post-sale support is critical to maintaining uptime and maximizing the equipment’s lifespan. Be wary if a supplier cannot provide a clear and direct line for technical assistance. Key warning signs include:

- An unclear process for who to call for maintenance or troubleshooting.

- Support that is outsourced to a third-party call center with no direct knowledge of the machinery.

- No readily available inventory of common wear parts, leading to extended and costly downtime while you wait for shipments.

Focus on Price Over Performance

While budget is always a factor, a supplier whose primary selling point is being the “cheapest” option is cause for concern. The lowest upfront cost rarely translates to the best long-term value. Quality packaging machine suppliers will engage in a dialogue about your production goals, desired efficiency, and overall return on investment. They will discuss the Total Cost of Ownership (TCO), which factors in reliability, maintenance, and the cost of potential downtime. A supplier who avoids this conversation is selling a piece of metal, not a performance solution.

The Difference Between a Supplier and a True Partner

Selecting the right equipment is only one part of the equation for operational excellence. The company you choose to work with is equally critical. While many companies can sell you a machine, the best packaging machine suppliers operate as true partners, investing in your success long after the initial sale is complete. A transaction ends when the invoice is paid; a partnership is just beginning.

A partner acts as an extension of your team. Their engineers and support staff work to understand your specific challenges, production goals, and long-term vision. This collaborative approach ensures the equipment you invest in not only meets today’s demands but is also positioned to support your future growth. The focus shifts from a simple sale to achieving optimal, sustained performance for your entire operation.

Commitment to Your Long-Term Success

A partner demonstrates their commitment through tangible, ongoing support designed to maximize your return on investment. They look beyond the immediate installation and help you build a foundation for future efficiency. This includes:

- Strategic Growth Planning: Helping you anticipate and plan for future production increases, ensuring your packaging line can scale with your business.

- Equipment Upgrade Paths: Offering equipment buyback or trade-in programs that provide a clear, cost-effective path to upgrading technology as your needs evolve.

- Comprehensive Training: Providing in-depth training for your operators and maintenance staff to ensure high performance, safety, and operational self-sufficiency.

Proactive Integration and Automation Support

A true partner understands that a new machine does not operate in a vacuum. They take a holistic view of your production line, providing expert guidance on seamless integration. Their goal is to improve your entire process, not just sell a single piece of equipment. This support often involves advising on upstream and downstream automation opportunities, from simple conveyors to advanced robotic palletizing systems. By optimizing the flow of your entire line, they help eliminate bottlenecks and unlock new levels of efficiency.

When you evaluate packaging machine suppliers, look for one that is ready to build a lasting relationship. Choosing a partner committed to your success is the first step toward a more reliable and profitable operation. Discover the difference a true partnership can make.

Why a US-Based Manufacturer is Your Most Reliable Choice

After comparing technical specifications and features, the final decision often comes down to the supplier themselves. When evaluating potential packaging machine suppliers, choosing an Original Equipment Manufacturer (OEM) located in the United States provides a strategic advantage that directly impacts your operational efficiency and long-term return on investment. It’s a choice that ensures a direct line to expertise, superior quality control, and a partnership built for decades of reliable performance.

Unmatched Quality and Reliability

Domestic manufacturing guarantees your equipment is built under some of the world’s most stringent quality control standards. From the grade of steel used in the frame to the precision of the electronic components, every element is meticulously managed from start to finish. The ‘Made in the USA’ mark is a trusted symbol of superior craftsmanship. This commitment to quality means you invest in a machine built with robust components engineered for maximum uptime and a longer operational lifespan, minimizing costly downtime and maintenance.

Direct Access to Engineering and Service

Working with a US-based OEM eliminates the frustrating layers of communication found with overseas suppliers or third-party distributors. When you need support, you have a direct line to the very engineers and technicians who designed and assembled your machine. This seamless communication removes language barriers and time zone delays, ensuring your needs are understood and addressed promptly. This direct access provides critical advantages:

- Faster Troubleshooting: Resolve operational issues in hours, not days.

- Efficient Customization: Discuss modifications and unique requirements directly with the engineering team.

- Reliable Parts Availability: Get domestically sourced replacement parts shipped quickly to keep your line running.

Experience and Stability You Can Trust

A manufacturer’s history is a powerful indicator of its product reliability and financial stability. A long-established American company has weathered economic shifts and technological changes by consistently delivering value. At Choice Bagging Equipment, we have been a trusted partner and manufacturer since 1978, building durable, high-performance systems that stand the test of time. When you choose an experienced domestic supplier, you invest with confidence. Ready to build a more reliable packaging line? Contact our experts to discuss your project needs.

Secure Your Production with a Trusted Partner

Selecting the right equipment is a critical decision impacting your long-term operational efficiency. As this guide has shown, evaluating potential vendors requires looking beyond technical specifications and price tags. The best packaging machine suppliers distinguish themselves by acting as true partners—they are committed to your success, offer transparent communication, and provide the unmatched reliability that comes with US-based manufacturing.

At Choice Bagging Equipment, we embody this partnership approach. As a trusted manufacturer since 1978, we build performance and durability into every piece of equipment we sell. Our commitment is proven by our dedicated engineering and field service support, ensuring your machinery operates at peak efficiency for decades to come.

Invest in a solution that is proudly made in the USA, guaranteeing superior quality control and responsive service. Your equipment is the core of your production line. Speak with a Choice Bagging expert to find your reliable packaging solution. Invest confidently and build a foundation for lasting operational success.

Frequently Asked Questions About Packaging Machine Suppliers

What’s the difference between a packaging machine supplier and a manufacturer?

A manufacturer designs, engineers, and builds the equipment in-house, offering direct access to deep technical expertise and custom solutions. They control the entire process, ensuring quality and performance. In contrast, a supplier or distributor often represents multiple brands. While they provide options, they may lack the specialized engineering knowledge for complex integrations or in-depth troubleshooting. For unmatched reliability, partnering directly with a manufacturer is the superior choice for your long-term operational success.

How important is ‘Made in the USA’ for industrial machinery?

For industrial packaging machinery, ‘Made in the USA’ is a powerful indicator of quality, durability, and support. It signifies adherence to stringent manufacturing standards, higher-quality materials, and superior craftsmanship, resulting in equipment built to last for decades. Furthermore, it ensures faster access to domestic technical support and a reliable supply chain for spare parts. This commitment minimizes costly downtime and protects your investment in operational efficiency and performance over the long term.

What information should I have ready before I contact a supplier?

To ensure a productive consultation, prepare key details about your operation. This includes your product’s characteristics (e.g., density, flowability), desired bag or container type and size, and your target production rate in bags per minute. Also, have information on your facility’s available space, power supply, and any existing upstream or downstream equipment. This data allows an expert to recommend a precise, high-performance solution tailored to your specific needs from the very first conversation.

How do I calculate the Total Cost of Ownership (TCO) for a packaging machine?

Total Cost of Ownership (TCO) extends far beyond the initial purchase price. A true calculation must include the upfront cost plus installation, operator training, scheduled maintenance, and the cost of spare parts over the machine’s lifespan. Critically, you must also factor in the potential cost of downtime. Investing in a highly reliable, durable machine with minimal moving parts significantly lowers your long-term TCO by maximizing uptime and operational performance for years to come.

What kind of after-sales support and training should I expect from a top-tier supplier?

A top-tier partner provides comprehensive support that guarantees performance from day one. This should include on-site installation and commissioning by factory-trained technicians, as well as thorough operator training to ensure safe and efficient use. Expect clear, detailed documentation and manuals. Most importantly, look for responsive, accessible technical support and a commitment to stocking critical spare parts to ensure your operation maintains maximum uptime and productivity for the life of the equipment.

Can a supplier help me automate my entire packaging line?

Yes, but the most competent packaging machine suppliers are more than just vendors; they are integration partners. A true expert can design and implement a complete, seamless automated line. This includes integrating the bagger or filler with conveyors, checkweighers, sealers, and robotic palletizers. By managing the entire project, they ensure all components work in unison to maximize your throughput, reduce labor costs, and deliver a reliable, end-to-end packaging solution built for peak efficiency.

Recent Comments