In the competitive landscape of manufacturing, efficiency is critical. At Choice Bagging, we understand that improving bagging speed and accuracy can significantly enhance overall productivity and reduce costs. In this text, we’ll explore key strategies and innovations that can help streamline your bagging processes, ensuring fast and precise packaging for a variety of materials. Whether you’re dealing with dry powders, bulk solids, or other specialty products, optimizing your bagging systems is essential for success.

Understanding Bagging Systems

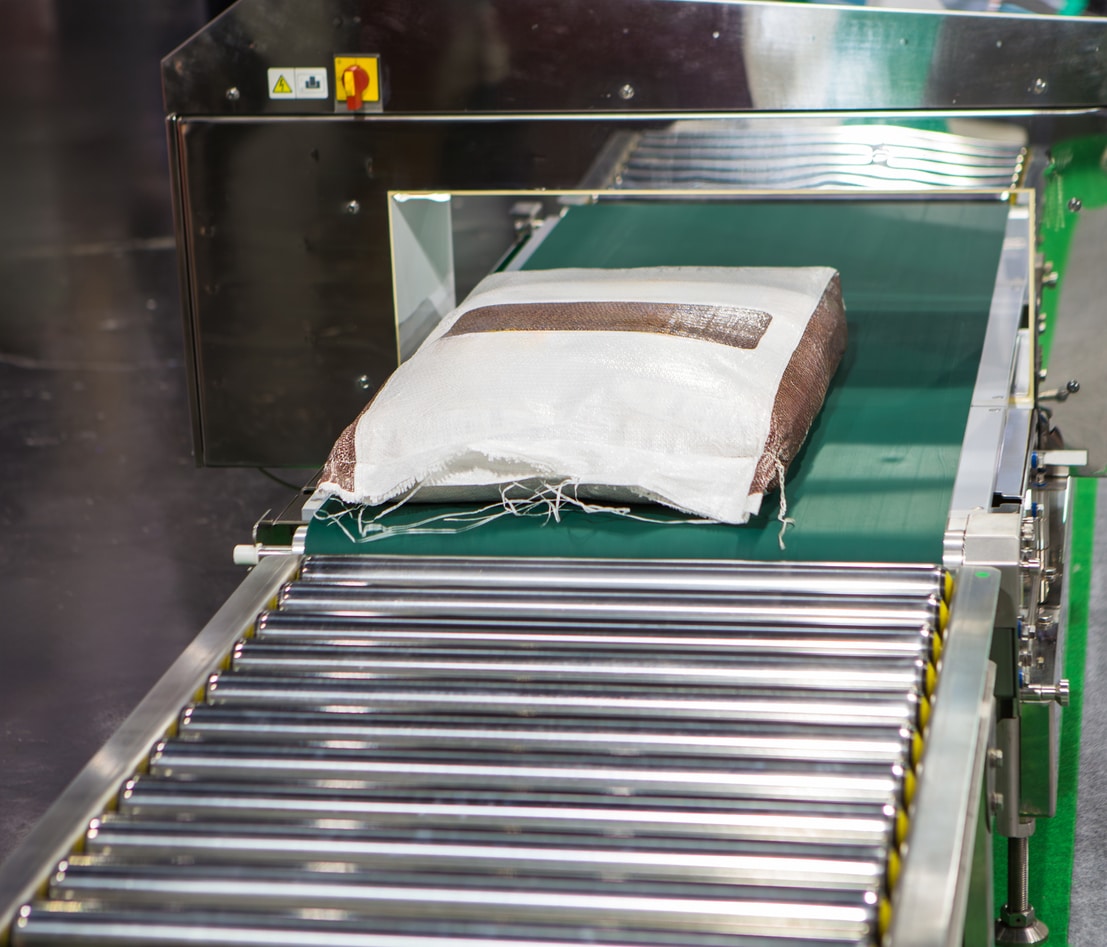

Bagging systems are vital to the packaging industry. They come in different forms: from manual to semi-automatic and fully automatic lines. These systems handle the entire packaging process, opening, filling, weighing, sealing, and often labeling bags, all in one seamless flow.

Modern bagging machinery includes Vertical Form-Fill-Seal (VFFS) systems, bulk bag fillers, and integrated poly-bagging systems. Each of these machines can significantly enhance the productivity of your packaging operations by focusing on diverse material types, such as flake, granule, or caked solids. Understanding the nuances of these systems is the first step in improving speed and accuracy.

The Importance of Speed and Accuracy in Bagging

In our fast-paced manufacturing environment, speed and accuracy are paramount. Higher throughput, measured in bags per minute, directly correlates with increased production capacity and lower labor costs. But, speed should not come at the expense of accuracy.

Aiming for precision is essential: deviations can lead to costly issues such as overfilling, underfilling, and compliance problems. For bulk materials, maintaining a filling accuracy within ±1 lb is crucial. By prioritizing both speed and accuracy, manufacturers can maximize their operational efficiency and minimize waste.

Optimizing Bagging Speed

To enhance bagging speed, we recommend adopting the following strategies:

- Use Fully Automatic Systems: Fully automated or continuous-motion bagging systems support high-volume production. These advanced machines help a seamless flow of operations.

- Match Machine Capacity to Demand: Assess your throughput needs. High-end systems can achieve remarkable speeds, up to 60 units per minute or 1,200 packages per hour. Setting realistic goals based on demand helps in achieving efficiency without overburdening your systems.

- Integrate Ancillary Equipment: Implementing conveyors, checkweighers, and palletizers can optimize the entire workflow, eliminating downtime.

- Reduce Changeover Times: Invest in modular tooling and recipe-based controls that minimize the time needed for equipment adjustments between different products.

Key Factors Affecting Bagging Accuracy

To ensure accurate bagging, several critical factors must be considered:

- Precision Weighing Systems: Employing net-weigh or multihead weighing technologies before filling ensures the highest degree of accuracy for each bag.

- Regular Calibration: Utilizing calibrated load cells and precision dosing systems helps prevent underfilling or overfilling.

- Appropriate Bag Sizing: Selecting the correct bag size and material stabilizes the target for filling, aiding the filling process.

Routine Maintenance: Regular upkeep of your machinery is essential to prevent variances and drifts in weight, ensuring consistent performance.

Technological Innovations in Bagging

Embracing modern technologies can drastically improve bagging processes. Here are some innovations to consider:

- AI and Machine Learning Integration: Systems utilizing AI for poly-bagging can adapt to variable weights and sizes, significantly reducing manual errors by up to 40%.

- Real-Time Analytics: Implementing monitoring systems provides valuable insights, spotting anomalies and enabling predictive maintenance to avoid costly downtimes.

- Enhanced Automation: High-speed automated equipment ensures tighter weight control while maintaining high throughput rates, which is beneficial as your production scales.

A useful parallel can be drawn between manufacturing bagging and the ‘bagging technique’ in machine learning. In data science, ensemble learning methods like bootstrap aggregating (bagging) use multiple models—often decision trees or random forests—to improve prediction accuracy and overall model performance. In the bagging technique, base learners or weak learners are trained independently on different random subsets (bootstrap samples) drawn from the original dataset or training set. The final prediction is an aggregate of the individual models, which helps reduce variance and improve predictive performance, especially on new data.

For example, a bagging classifier or random forests algorithm implemented in scikit learn trains several decision trees on different random subsets of the original data. These algorithms are key advantages in machine learning, as they can reduce variance, handle high variance or high bias models, and boost predictive performance for both classification and regression tasks. Deep learning models can also benefit from similar methods. Algorithms like bagging and random forests use individual data points from the original data to create random subsets, and a single model such as a single decision tree may have limitations compared to an ensemble approach. Choosing the right methods and implementation has a direct impact on business outcomes, just as selecting the right bagging machine is critical in manufacturing. Ensemble learning methods are useful tools for improving model performance and ensuring robust predictions.

How to Choose the Right Bagging Machine

Selecting the right bagging machine is a critical decision that directly impacts your production line’s efficiency, output, and labor costs. Start by evaluating the specific characteristics of the product you need to package—whether it’s fine powders, granules, or larger items like pet food, each requires a machine with tailored features such as precise weighing, dosing systems, or higher capacity. Next, consider your production requirements: determine the desired speed and output to ensure the machine can keep pace with your business goals without creating bottlenecks.

It’s also important to assess how well the bagging machine will integrate with your existing production line. Compatibility with upstream and downstream equipment, as well as the level of automation, can make a significant difference in streamlining operations and reducing manual intervention. Don’t overlook factors like maintenance costs, energy efficiency, and the quality of manufacturer support and after-sales service, as these can influence long-term operational costs and machine reliability. By carefully weighing these considerations, you can invest in a bagging machine that not only meets your current needs but also supports future growth, delivering efficient, high-quality output while keeping labor costs in check.

Integrating Bagging Machines into the Production Line

Seamless integration of a bagging machine into your production line is essential for maximizing efficiency and minimizing labor costs. Begin by analyzing your current production layout to identify the most effective placement for the bagging machine, ensuring a smooth flow of materials and products. Positioning the machine strategically can help reduce manual handling and eliminate repetitive tasks, allowing your team to focus on higher-value activities.

Connect the bagging machine with other key equipment—such as conveyors, fillers, and sealers—to create a unified, automated workflow. This integration not only boosts overall machine performance but also enhances product quality by reducing the risk of errors and inconsistencies. Additionally, invest in comprehensive training for your staff so they are proficient in operating and maintaining the new equipment. With a well-integrated bagging machine, your production line will benefit from increased productivity, lower labor costs, and consistently high-quality output.

Key Considerations for Bagging Machine Maintenance

Maintaining your bagging machine is vital for ensuring consistent accuracy, optimal performance, and long-term reliability. Establish a routine maintenance schedule that includes daily, weekly, and monthly inspections of critical components such as weighing systems, conveyor belts, and seals. Keeping the machine clean and free from dust and debris is essential, as even minor buildup can impact the accuracy and efficiency of the bagging process.

Consider implementing a predictive maintenance program that leverages data and sensors to monitor machine health and detect potential issues before they lead to downtime. This proactive approach not only extends the lifespan of your equipment but also helps maintain the highest quality standards by ensuring each bag is filled to the precise weight. Make sure your team is well-trained in maintenance procedures and has access to the necessary tools and spare parts. By prioritizing regular and predictive maintenance, you can minimize unexpected repairs, reduce operational costs, and guarantee reliable, high-performance bagging that meets the demands of your business.

Training and Workforce Management

Our workforce plays a pivotal role in achieving high bagging speed and accuracy. Consider the following approaches:

- Thorough Training Programs: It’s vital to train operators in machine setup, basic troubleshooting, and quality inspections. Well-trained staff helps maintain uptime and accuracy.

- Supervision of Automated Lines: One skilled operator can effectively manage multiple automated systems, which allows for a redistribution of labor towards higher-value tasks.

To sum up, we believe that improving bagging speed and accuracy involves a multifaceted approach. By integrating high-precision automated machinery, optimizing your line, employing data-driven monitoring, and empowering our workforce through training, we can achieve notable enhancements in our bagging operations. With this comprehensive strategy, we not only maximize efficiency but also maintain the quality of our products.

Frequently Asked Questions

What strategies can improve bagging speed?

To enhance bagging speed, consider adopting fully automatic systems, integrating ancillary equipment, reducing changeover times, and matching machine capacity to production demand.

Why is accuracy important in bagging processes?

Accuracy in bagging prevents costly issues like overfilling and underfilling, ensures compliance, and is crucial for maintaining product quality, particularly with bulk materials.

How can technology enhance bagging accuracy?

Technological innovations like AI integration and precision weighing systems can significantly improve bagging accuracy by reducing manual errors and ensuring precise filling.

What is the role of training in improving bagging speed and accuracy?

Training operators on machine setup and quality inspections is vital; knowledgeable staff can optimize operations and minimize errors, thereby enhancing speed and accuracy.

How do fully automatic bagging systems increase efficiency?

Fully automatic bagging systems streamline the entire packaging process, handling tasks from filling to sealing at high speed, which boosts overall production capacity.

What factors affect bagging system performance?

Bagging system performance is influenced by precision weighing, calibration of equipment, appropriate bag sizing, and routine maintenance, all crucial for maintaining efficiency and accuracy.

Recent Comments