A high-performance bulk bag unloader is a powerful asset for any operation, but unlocking its full potential requires more than just installation. Improper handling can lead to significant risks-from operator injury and costly product spills to uncontrolled dust that compromises facility safety. This uncertainty can turn a valuable piece of equipment into a source of operational anxiety, preventing you from achieving the efficiency and reliability you invested in.

This guide provides the expert framework to operate your equipment with confidence and precision. We will walk you through a complete, step-by-step process designed to establish a safe, repeatable procedure for your team. You will learn essential pre-use safety checks, the correct method for loading and discharging bags to prevent waste, and the routine maintenance practices that ensure the longevity and peak performance of your machine. Master these steps to protect your operators, maximize material transfer, and maintain a clean, productive work environment.

Key Takeaways

-

Prioritize operational safety by implementing a comprehensive pre-use checklist and confirming all operators have received proper training.

-

Understand the correct, sequential operating procedure for your specific bulk bag unloader to ensure both operator safety and material flow efficiency.

-

Learn to identify and safely resolve common material handling issues, such as product bridging and dust containment, without interrupting production.

-

Master the proper shutdown and maintenance protocols to extend equipment life, prevent downtime, and maintain a safe working environment.

Table of Contents

-

Pre-Operation Safety Checklist: Your Foundation for Safe Unloading

-

The Operating Procedure: A Step-by-Step Guide to Discharging

-

Managing Common Challenges: Bridging, Dust, and Partial Batches

-

Choosing the Right Unloader for Maximum Safety and Efficiency

Pre-Operation Safety Checklist: Your Foundation for Safe Unloading

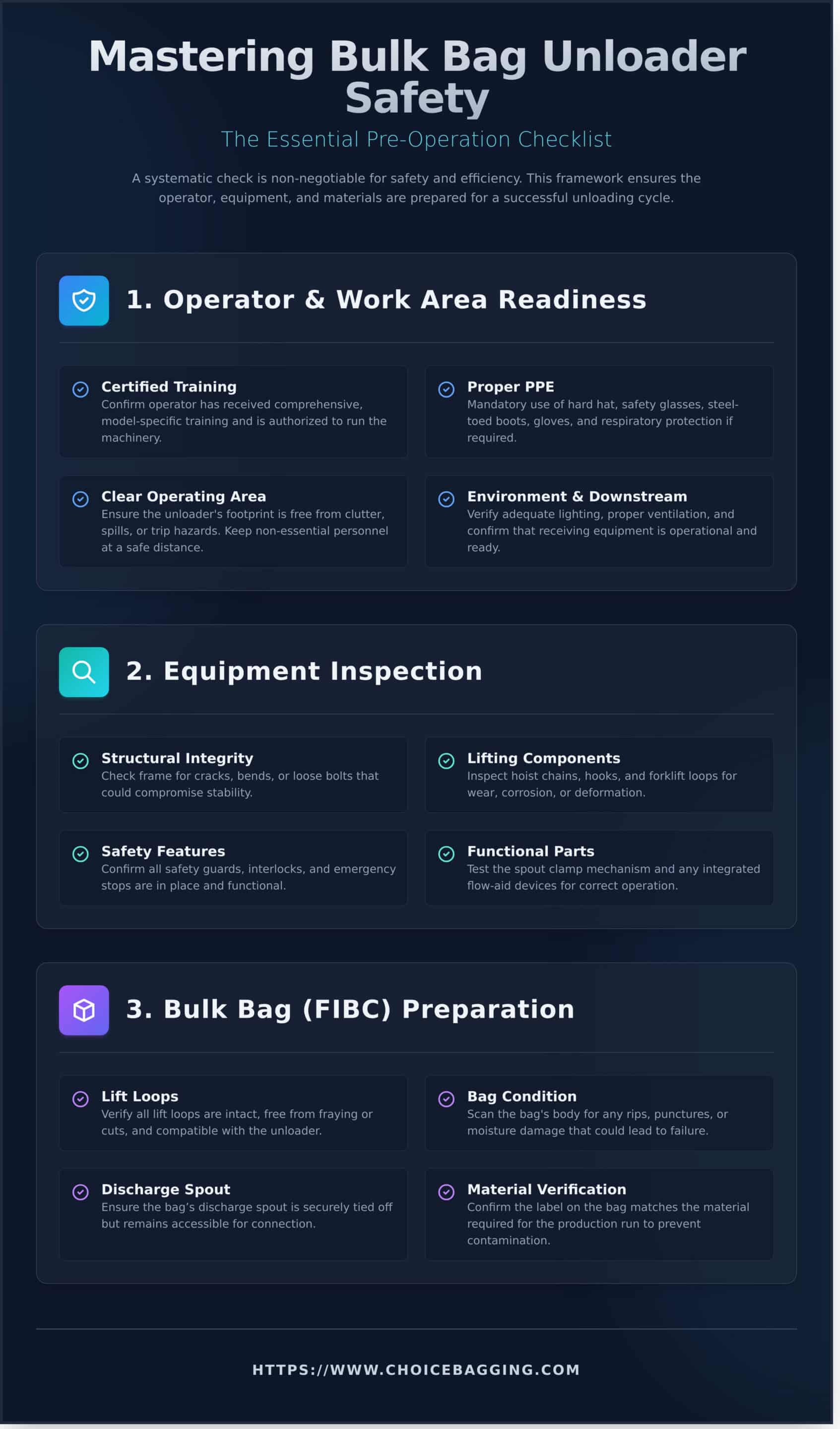

In any bulk material handling operation, safety is not just a priority-it is the foundation of efficiency and reliability. Before engaging any bulk bag unloader, a systematic pre-operation check is non-negotiable. This process ensures that the operator, equipment, and materials are prepared for a successful unloading cycle. The first step is confirming that the operator has received comprehensive, model-specific training and is fully authorized to run the machinery.

To visualize the key components and operation, watch this overview of a bulk bag unloader system in action:

Beyond training, proper Personal Protective Equipment (PPE) is mandatory. This typically includes a hard hat, safety glasses, steel-toed boots, and gloves. Depending on the material being handled, respiratory protection may also be required to prevent dust inhalation. A clear, unobstructed operating area is equally critical. Ensure all personnel not involved in the unloading process are a safe distance away and that the unloader’s footprint is free from tools, clutter, or spills.

Equipment Inspection

A machine in optimal condition is a safe machine. Before every use, perform a quick but thorough inspection of the unloader itself. This simple habit prevents equipment failure and protects your team.

-

Structural Integrity: Carefully check the frame for any signs of stress, such as cracks, bends, or loose bolts that could compromise stability.

-

Lifting Components: Inspect hoist chains, hooks, and forklift loops for wear, corrosion, or deformation. A compromised lift point is a significant safety hazard.

-

Safety Features: Confirm that all safety guards, light curtains, and emergency stops are in place and fully functional. Never operate a machine with disabled interlocks.

-

Functional Parts: Test the spout clamp mechanism and any integrated flow-aid devices to ensure they are working correctly.

Bulk Bag (FIBC) Preparation

A secure unloading process begins with a properly prepared bag. Before lifting, a thorough inspection of the Flexible Intermediate Bulk Container (FIBC) is essential to prevent material spills and equipment damage.

-

Lift Loops: Verify all lift loops are intact, free from fraying or cuts, and are compatible with the unloader’s lifting frame.

-

Bag Condition: Scan the bag’s body for any rips, punctures, or signs of moisture damage that could lead to failure during the lift or discharge.

-

Discharge Spout: Ensure the bag’s discharge spout is securely tied off but remains accessible for connection to the unloader’s receiving hopper.

-

Material Verification: Confirm the label on the bag matches the material required for the production run to prevent process contamination.

Work Area Assessment

The immediate environment around the bulk bag unloader must be secure and ready to support the operation. A quick assessment of the work area prevents common accidents and ensures a smooth material transfer.

-

Floor Conditions: The floor must be clean, dry, and completely free of debris, cords, or other trip hazards.

-

Utilities & Environment: Confirm there is adequate lighting for clear visibility and proper ventilation to manage any dust generated during discharge.

-

Downstream Readiness: Ensure that the receiving equipment, such as screw conveyors or pneumatic transfer systems, is operational and ready to accept material.

The Operating Procedure: A Step-by-Step Guide to Discharging

A successful discharge process prioritizes both operator safety and operational efficiency. Following a proven, systematic procedure ensures that material is handled correctly, minimizing product loss, preventing dust contamination, and protecting personnel. This guide outlines the three essential phases of operating a high-performance bulk bag unloader, from lifting the bag into place to achieving a complete and controlled material discharge.

Step 1: Lifting and Positioning the Bag

Properly lifting and centering the bulk bag is the foundation of a safe unloading cycle. All lifting must be performed smoothly and deliberately, adhering to established FIBC safe handling guidelines to prevent equipment damage or injury. The primary goal is to securely position the bag directly over the unloader’s receiving hopper without swinging or shock-loading the frame.

-

For Hoist and Trolley Systems: Ensure the lifting frame hooks are securely attached to all of the bag’s lift loops. Never lift a bag by fewer than the total number of loops provided.

-

For Forklift Systems: Guide the forklift tines so they are fully engaged through the bag loops. The forks should be spaced correctly to provide stable, level support.

Lift the bag slowly until it is clear of all obstructions, then carefully maneuver it until it is centered above the unloader.

Step 2: Securing the Discharge Spout

Creating a sealed, dust-tight connection is critical for maintaining a clean work environment and preventing product waste. Once the bag is suspended over the hopper, lower it just enough for an operator to safely access the discharge spout. Untie the spout and guide it down through the access tube and iris valve or spout clamp system. Secure the clamp mechanism tightly around the spout. This connection ensures your material flows cleanly into your process or onto downstream equipment like bag handling conveyors, completely isolating the product from the plant environment.

Step 3: Initiating and Monitoring Material Flow

With the spout secured, you can safely begin the discharge. Lower the bag completely until its full weight is resting on the unloader’s support dish or massage paddles. This action seats the bag properly and prepares it for emptying. To begin, open the iris valve or release the spout clamp. Material will begin to flow into the hopper. It is crucial for an operator to observe the initial flow, confirming it is consistent and unobstructed. If material flow becomes sluggish or bridges, engage the integrated flow-promotion devices, such as bag massagers or vibrators, as needed. While our bulk bag unloader systems are engineered for unmatched reliability, an operator should never leave the machine unattended during the discharge cycle.

Managing Common Challenges: Bridging, Dust, and Partial Batches

Even the most efficient bulk material processes encounter operational challenges. A high-performance bulk bag unloader is engineered to solve these issues before they cause downtime or safety hazards. An experienced equipment partner anticipates these common problems-material bridging, fugitive dust, and the need for partial bag discharging-and integrates reliable solutions directly into the system design for seamless operation.

Resolving Material Bridging and Compaction

Material bridging occurs when compacted or hygroscopic product forms a solid, self-supporting arch over the bag spout, completely stopping material flow. To resolve this safely and efficiently, well-designed unloaders feature pneumatic bag agitators. These devices gently massage the lower portion of the bag, breaking the bridge and restoring flow without compromising the bag’s integrity. Under no circumstances should operators strike the bag or frame with hammers. This dangerous practice can damage equipment and violates the core principles of safe handling found in OSHA’s material handling regulations.

Advanced Dust Control Techniques

Controlling fugitive dust is critical for maintaining a safe, clean, and compliant facility. Our bulk bag unloader systems provide a sealed and contained environment to manage dust at the point of origin. For maximum effectiveness, operators should follow these best practices:

-

Ensure the bag spout access chamber is sealed and the spout clamp is fully engaged before untying the bag spout.

-

Connect the integrated dust collection port to your facility’s dust collector to create negative pressure within the sealed system.

-

Verify all seals and connections are secure to prevent any dust from escaping during the discharge cycle.

Handling Partial Bag Discharges

Not every application requires a full bulk bag of material. For processes requiring partial batches, the ability to safely stop and restart material flow is essential. The procedure is straightforward and designed for reliability. First, close the integrated iris valve or flow control valve completely to stop the discharge. Once the flow has ceased, the operator can safely retie the bag spout. The bag, now containing the remaining material, can be removed from the unloader without spills and stored for later use, maximizing material usage and minimizing waste.

Post-Operation: Shutdown, Cleaning, and Maintenance

A high-performance bulk bag unloader is engineered for durability, but its long-term reliability and safety depend on consistent post-operation procedures. Following a structured shutdown, cleaning, and maintenance protocol protects your investment, ensures operator safety, and maintains peak operational efficiency for decades to come. This commitment to care is fundamental to maximizing your return on investment.

Safe Shutdown and Bag Removal

Once the discharging process is complete, the first step is to confirm the bag is entirely empty using flow indicators or a visual check. Before detaching, raise the bag support dish slightly to create slack, allowing operators to safely retie the bag spout to contain residual dust. Finally, use the hoist to lift the empty bag clear of the unloader frame and transport it to the designated recycling or disposal area according to your facility’s protocols.

Cleaning and Inspection

After every use, a routine cleaning and inspection are essential. Wipe down all accessible surfaces to remove product dust and prevent cross-contamination. For food-grade or pharmaceutical applications, adhere strictly to your established Clean-in-Place (CIP) or other sanitary protocols. A quick visual inspection of the spout clamp mechanism, access door seals, and frame welds can identify potential issues before they become problems. If you notice signs of wear or damage that require professional attention, our expert field service team is available to provide on-site support and ensure your equipment remains in prime condition.

Routine Maintenance Schedule

A preventative maintenance schedule is the cornerstone of equipment longevity. We recommend a tiered approach to keep your system running flawlessly:

-

Weekly: Inspect all pneumatic lines for leaks or damage and verify that electrical connections are secure.

-

Monthly: Lubricate all moving components, such as hoist chains or actuator pivot points, as detailed in your equipment’s user manual.

-

Annually: Schedule a comprehensive inspection of the structural frame, welds, and hoist system. This ensures the foundational integrity of your bulk bag unloader.

By integrating these simple yet critical steps into your operational workflow, you transform routine tasks into a powerful strategy for maximizing uptime. This commitment to maintenance underpins the reliability you expect from a high-quality system. For guidance on creating a custom maintenance plan for your specific application, contact our team of experts today.

Choosing the Right Unloader for Maximum Safety and Efficiency

Selecting the right bulk bag unloader is a critical investment in your plant’s productivity and, most importantly, its safety. The design of your equipment directly dictates how securely and efficiently your team can handle materials. A well-chosen system minimizes risk, reduces downtime, and protects your product from contamination, ensuring a reliable return on your investment.

Forklift-Loaded vs. Hoist-and-Trolley Systems

The primary consideration is how you will lift and position the bulk bags. Forklift-loaded models offer speed and convenience in facilities where lift trucks are readily available and in constant use. Conversely, integrated hoist-and-trolley systems are the superior choice for areas with limited forklift access, low headroom, or where a dedicated, fixed unloading station optimizes workflow. A thorough analysis of your existing equipment and process flow is essential to making the right choice.

Key Features for a Safer, More Productive Operation

Beyond the loading mechanism, specific engineering features are non-negotiable for ensuring a safe and efficient process. Look for a system that includes:

-

Dust-Tight Spout Clamping: A secure, sealed connection is vital to prevent airborne dust, protecting operator respiratory health and eliminating product waste.

-

Flow-Promotion Devices: Integrated agitator paddles or vibration systems break up compacted materials, ensuring consistent flow and preventing the need for unsafe manual intervention like hammering on the bag.

-

Robust Frame Design: The frame must be engineered to exceed the stability requirements for a full, heavy bag, guaranteeing structural integrity and operator safety under maximum load.

Integrating with Your Production Line

A high-performance unloader must function as a seamless part of your larger process. Ensure its discharge rate is calibrated to match the capacity of your downstream conveyors, mixers, or bagging machines to prevent bottlenecks. It is also crucial to plan for how bags will be supplied to the station and how empty bags will be removed and compacted. Our bulk bag unloaders are engineered for seamless integration and unmatched reliability.

Making an informed decision requires a partner who understands these complexities. By carefully evaluating your operational needs against these key design and safety features, you can invest confidently in a solution built for long-term performance. For expert guidance in selecting the right system for your application, contact our team for a consultation .

Elevate Your Operations with Safe and Reliable Bulk Bag Discharging

Mastering the operation of your equipment is about more than just efficiency; it’s a commitment to safety and operational excellence. By consistently following pre-operation checklists, adhering to a systematic discharging procedure, and performing regular maintenance, you protect your team and your investment. These disciplined practices are the bedrock of a productive and secure workflow, ensuring every discharge is both successful and safe.

Ultimately, the reliability of your entire process begins with the quality of your machinery. A well-engineered bulk bag unloader is designed to minimize common challenges and make safe operation intuitive, forming the foundation of a dependable system that empowers your team to work with confidence.

Choosing the right partner is as critical as choosing the right equipment. Since 1978, Choice Bagging Equipment has built a legacy of trust and performance with systems proudly Made in the USA. We back our durable machinery with expert engineering support and dedicated field service. Invest confidently in a solution built to last. View our American-made bulk bag unloaders and invest in reliability.

Frequently Asked Questions About Bulk Bag Unloaders

What types of materials are best suited for a bulk bag unloader?

Bulk bag unloaders are engineered for high-performance handling of a wide range of dry, free-flowing materials. This includes fine powders like cement or flour, granular products such as sand and plastic pellets, and even larger materials like seeds or small aggregates. The key to reliable performance is matching the unloader’s features, such as flow-promotion devices, to the specific characteristics of your material to ensure consistent and efficient discharge every time.

How much training does an operator need to safely use this equipment?

Our systems are designed with easy-to-use controls to minimize the learning curve. Basic operator training typically covers standard operating procedures, bag loading, and safety protocols, which can often be completed in just a few hours. We provide comprehensive documentation and support to ensure your team is competent and confident. Proper training is a critical investment in both operator safety and the long-term reliability of your equipment, ensuring dependable performance for years to come.

What are the most critical safety features to look for when buying an unloader?

When investing in an unloader, prioritize features that guarantee operator safety and operational integrity. Look for a robust support frame, safety interlock gates that prevent access during operation, and clearly marked emergency stop buttons. An enclosed system with a dust-tight bag spout interface is also crucial for protecting workers from hazardous materials and preventing dust explosions. These are not optional add-ons; they are fundamental components of a durable and safe machine.

Can a bulk bag unloader handle both powders and granular materials?

Absolutely. A well-designed bulk bag unloader can be configured to efficiently handle both fine powders and coarse granular materials. The key is customization. For powders, features like bag massagers and vibration are used to promote flow and prevent bridging, while granular materials require a focus on controlled discharge. By selecting the right components for your specific application, a single system can offer the versatility and performance needed to manage diverse material types reliably.

How often should I perform a full safety inspection on my bulk bag unloader?

We recommend a complete safety inspection be conducted by a qualified technician at least annually, in line with your facility’s preventative maintenance schedule. In addition, operators should perform daily pre-use checks on critical components like safety interlocks, hoist mechanisms, and control systems. This consistent attention to detail is essential for ensuring the long-term durability and safe performance of your equipment and protecting your most valuable asset: your personnel.

What is the best way to control dust when unloading fine powders?

The most effective method for dust control is a completely enclosed system. This begins with a dust-tight spout-clamping mechanism that creates a secure seal between the bag and the unloader. For maximum containment, integrate this with a dust collection port that connects to your facility’s central dust collector. This combination not only protects your operators from exposure but also prevents product loss and maintains a clean, compliant, and efficient work environment.

Recent Comments