In any industrial bagging operation, accuracy is profit. Even minor inconsistencies in bag weights lead to significant product giveaway, while slow filling cycles create production bottlenecks that directly impact your bottom line. The heart of a high-performance bagging line is its weighing system. Selecting the right industrial weigher is not just an equipment choice; it is a critical business decision that defines your operational efficiency and profitability.

This comprehensive guide is designed to provide the clarity you need to invest confidently. We will explore the different types of industrial weighing systems, from net weigh to gross weigh fillers, and explain how each technology functions. You will gain the expert knowledge needed to evaluate your specific product-whether it’s a fine powder, granular, or abrasive material-and select a durable, reliable solution engineered for your unique environment. Prepare to achieve consistent bag weights, increase throughput, and enhance your operation’s overall performance and profitability.

Key Takeaways

- An industrial weigher is more than a scale; it is a complete system engineered to control material flow and ensure precise, repeatable bag weights.

- The key to choosing the right weigher is understanding your product’s flow characteristics, as this dictates the ideal feeding technology for your application.

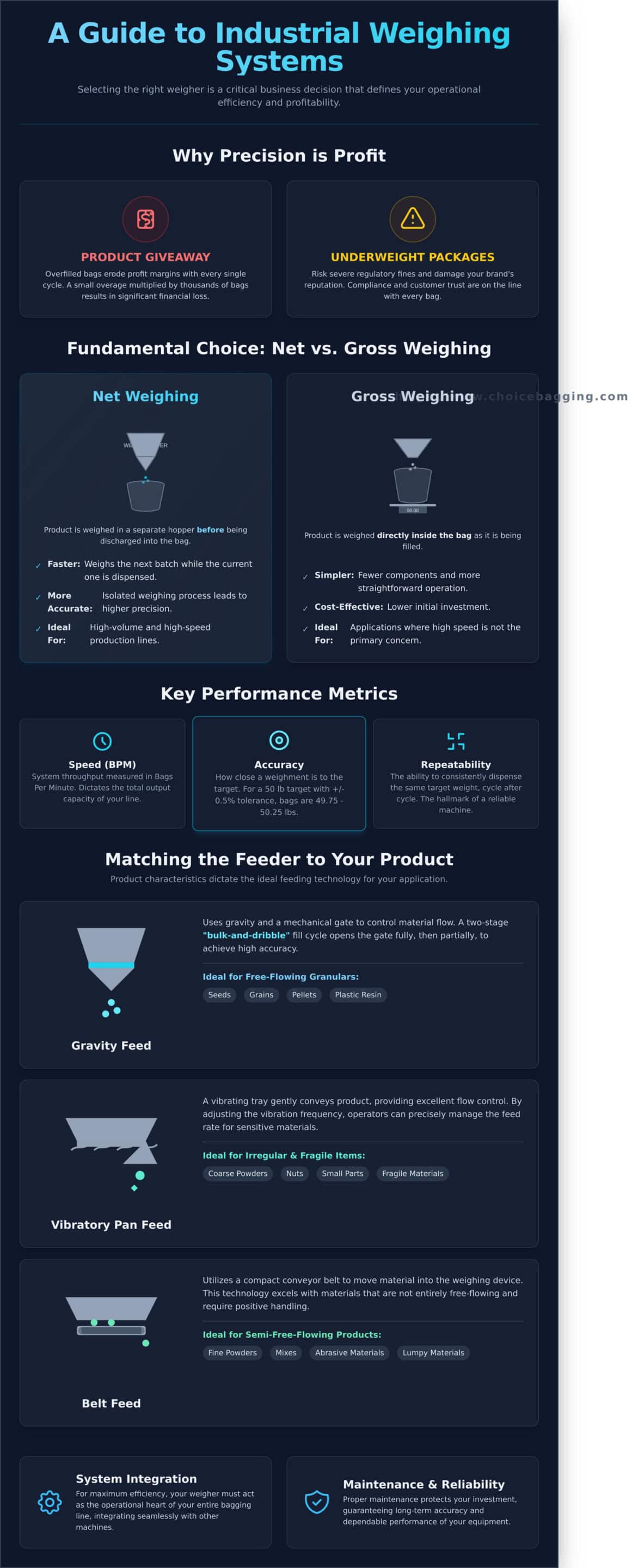

- For maximum efficiency, your weighing system must integrate seamlessly with other machines, acting as the operational heart of your entire bagging line.

- Proper maintenance is essential for protecting your investment and guaranteeing the long-term accuracy and reliability of your weighing equipment.

What is an Industrial Weigher and Why is it Critical for Bagging?

An industrial weigher is far more than a simple scale; it is an automated system engineered for the precise dispensing of bulk materials. While its core function is measurement, its true value lies in its ability to control product flow, accurately measure a target weight, and dispense it efficiently into a bag or container. This level of control is a modern evolution of foundational weighing scale technologies, adapted for high-throughput industrial environments.

To visualize how a weighing system integrates with a production line, watch this helpful video:

In automated bagging, precision is not a luxury-it is a direct driver of profitability. Every gram matters. Inaccuracy leads to two costly outcomes: product giveaway, where overfilled bags erode your profit margins with every cycle, and underweight packages, which risk severe regulatory fines and damage your brand’s reputation. For industries like agriculture, chemicals, and building materials, where thousands of bags are filled daily, a reliable weigher is a critical asset for protecting the bottom line.

Gross Weighing vs. Net Weighing: A Fundamental Choice

The two primary methods for weighing are gross and net. In gross weighing, the product is weighed directly inside the bag as it is being filled. This method is typically simpler and more cost-effective, suited for applications where speed is not the primary concern. In contrast, net weighing measures the product in a separate weigh hopper before discharging it into the bag. This allows the next batch to be weighed while the previous one is being dispensed, making it significantly faster and more accurate for high-volume operations.

Key Performance Metrics for Weighing Systems

When evaluating a weighing system, three metrics are paramount for ensuring performance and reliability:

- Accuracy: This measures how close a weighment is to the target weight, often expressed as a tolerance (e.g., +/- 0.5%). For a 50 lb target, this means every bag will be between 49.75 and 50.25 lbs.

- Speed: This is the system’s throughput, measured in Bags Per Minute (BPM) or weighments per minute. It dictates the overall output capacity of your bagging line.

- Repeatability: This is the system’s ability to consistently dispense the same target weight over and over. High repeatability is the hallmark of a dependable, high-performance machine.

Types of Weighing Technologies for Bulk Materials

When selecting equipment for a bagging line, it’s crucial to understand that industrial weighers for bulk materials operate differently from the multihead weighers common in snack food packaging. The primary distinction lies in the feeding mechanism-the method used to move product into the weigh hopper. The characteristics of your material, from flowability to particle size, directly determine the most reliable and efficient technology for your operation.

Every commercial weighing device must deliver repeatable accuracy, adhering to the stringent specifications outlined in standards like the NIST Handbook 44, and choosing the right feed style is the first step in achieving that goal.

Gravity Feed Weighers

This design uses gravity and a mechanical gate to control material flow. It is the ideal solution for free-flowing, granular products like seeds, grains, pellets, and plastic resin. To achieve high accuracy, the system employs a two-stage, bulk-and-dribble fill cycle. The gate opens fully for the bulk fill, then partially closes to “dribble” the remaining product, ensuring precise target weights with unmatched consistency.

Vibratory Pan Feed Weighers

A vibratory pan feeder uses a vibrating tray to gently convey product into the weigh hopper. This method provides excellent control and is perfect for irregular-shaped items or fragile materials that could be damaged by other systems. By adjusting the vibration frequency, operators can precisely manage the flow rate, making it suitable for products like coarse powders, nuts, and small parts that require careful handling.

Belt Feed Weighers

Belt feed weighers utilize a compact conveyor belt to move material into the weighing device. This technology excels with semi-free-flowing products or materials with inconsistent particle sizes, such as soil amendments, mulch, or certain animal feeds. Their robust design and ability to move larger volumes of product quickly make them a dependable choice for higher-speed bagging applications.

Auger / Screw Feed Weighers

Designed for challenging materials, an auger or screw feed weigher uses a rotating screw to volumetrically push product forward with precision. This is the definitive solution for fine powders and non-free-flowing materials like flour, cement, or fine chemical powders. The enclosed nature of the screw feeder also provides superior dust control, making it a critical component in systems like valve bag fillers.

Integrating a Weigher into a Complete Bagging Line

A high-performance weigher is the heart of any automated bagging line, but its precision is only as reliable as the system built around it. Achieving consistent, accurate weights requires seamless integration between every piece of equipment. Isolated performance is not enough; the entire line must function as a single, cohesive unit. This level of system-wide efficiency is managed through sophisticated control systems and PLCs (Programmable Logic Controllers), which ensure every component communicates and operates in perfect sync.

True system integration guarantees that the final filled bag meets stringent accuracy requirements. Achieving this level of precision requires a systems approach, adhering to the rigorous standards often developed through collaboration between government and industry bodies like the National Conference on Weights and Measures (NCWM).

Upstream Considerations: Consistent Material Supply

The performance of any weighing system begins before the product ever reaches it. A consistent and controlled material flow is critical for accuracy. This is typically achieved with a supply hopper or bin positioned directly above the weigher. This setup must carefully manage ‘head pressure’-the weight of the material in the hopper-as fluctuations can directly impact flow rate and weighing accuracy. For products that are prone to bridging or clumping, flow-aid devices are essential. These can include:

- Vibrators: To settle material and prevent voids.

- Air Pads: To fluidize fine powders for smoother flow.

Properly managing the infeed ensures the weigher receives a predictable stream of product, which is the foundation of repeatable accuracy.

Downstream Automation: From Filling to Palletizing

Once the precise weight is measured, the system must handle the product and bag with equal efficiency. The weigher discharges the product directly into a filling machine, such as a high-performance open mouth bagger, which securely holds the bag during the fill cycle. From there, automated bag handling conveyors take over, moving the filled bag to the next station. This seamless handoff prevents spills and maintains production speed. The line can be further automated by integrating bag sealers, checkweighers, and robotic palletizers, creating a fully automated process from bulk material to finished pallet.

How to Select the Right Weigher for Your Application

Selecting the right weigher for your bagging line is a critical decision that directly impacts your operational efficiency and profitability. The process begins not with the equipment, but with a thorough analysis of your product. This systematic approach ensures you invest in a solution built for performance and reliability, delivering accurate fills bag after bag.

Step 1: Analyze Your Material’s Characteristics

Before evaluating any equipment, you must have a complete profile of your material’s physical properties. These characteristics dictate how the product will behave during the weighing and filling process, making this the most important step in your decision.

- Flowability: Is your product free-flowing like plastic pellets, sluggish like brown sugar, or non-free-flowing like fibrous mulch?

- Bulk Density: This measurement of weight per unit of volume is essential for sizing the equipment correctly for your target weights.

- Other Factors: Consider properties like abrasiveness, corrosiveness, dust levels, and particle size, as they influence the required construction materials and overall system design.

Step 2: Match the Weigher Technology to Your Material

Once you have a clear material profile, you can confidently match it to the appropriate technology. Each type of weigher is engineered for optimal performance with specific product categories, ensuring both speed and accuracy.

- Gravity Weighers: The ideal choice for free-flowing, granular materials such as seeds, grains, and whole-bean coffee.

- Auger Weighers: Designed to handle fine, dusty, and non-free-flowing powders like flour, cement, or certain spices with precision.

- Belt Feed Weighers: Best suited for inconsistent or mixed-size products like aggregates, soil blends, or lumpy materials.

Step 3: Consider Production and Environmental Needs

Beyond the material itself, your operational goals and facility environment play a crucial role in the final system configuration. A holistic view ensures your equipment integrates seamlessly into your workflow.

- Speed Requirements: Define your target throughput in bags per minute (BPM) to ensure the system can meet present and future production demands.

- Facility Conditions: Assess the need for integrated dust collection to maintain a clean, safe workspace. For food-grade or corrosive applications, stainless steel construction is essential.

- Bagging Volume: For high-volume operations handling large quantities, dedicated bulk bag fillers may offer superior efficiency over traditional bagging lines.

Making the right choice involves careful consideration of these variables. As your partner in packaging, we believe in providing more than just equipment; we provide proven solutions. Consulting with an experienced equipment manufacturer is the most reliable way to ensure your investment delivers unmatched performance for years to come. Contact our experts to discuss your project today.

Weigher Maintenance and Performance Optimization

A high-performance weigher is an investment in your operational efficiency and profitability. To protect that investment and ensure decades of reliable service, a commitment to proper maintenance is essential. Proactive care is the key to maintaining long-term accuracy, minimizing unexpected downtime, and maximizing the return on your equipment.

The Importance of Regular Calibration

Calibration is the process of verifying and adjusting your equipment’s output against a known standard using certified test weights. Over time, factors like vibration, component wear, and changes in product density can cause accuracy to drift. We recommend a regular calibration schedule-typically quarterly, or more frequently for high-volume operations or abrasive materials-to guarantee every bag meets your precise weight targets and avoids costly product giveaway.

Common Troubleshooting for Inaccurate Weighments

When weighments become inconsistent, a few key areas should be inspected before assuming a major failure. Our technicians find that most issues stem from simple, correctable causes that can be resolved quickly on-site. Before calling for service, check the following:

- Material Buildup: Inspect for product residue on gates, weigh pans, or inside the hopper. Buildup can restrict flow or add unaccounted-for weight to the measurement.

- Inconsistent Product Supply: Ensure the upstream hopper is providing a steady, consistent flow of material. Starvation or surging can directly lead to inaccurate fills.

- Mechanical Inspection: Look for visible signs of damage to load cells, check for loose wiring, or identify any mechanical binding that could interfere with the weighing mechanism.

Sourcing Quality Parts and Expert Service

Maintaining peak performance requires using components designed for your specific equipment. Using genuine OEM parts guarantees the correct fit, material quality, and operational longevity, protecting your investment. For more complex issues, professional field service from trained technicians is the fastest way to diagnose problems and minimize costly downtime. When you partner with a trusted manufacturer, you secure more than just a machine; you gain access to the parts, expertise, and long-term support needed to keep your bagging line running at peak efficiency. Contact us to learn more about our comprehensive service and support programs.

Finding local, specialized support is also key to minimizing downtime. For instance, operators in Australia might work with a dedicated provider like Independent Scale Service to ensure their equipment meets regional standards and is serviced promptly.

Partner with the Experts for Unmatched Weighing Accuracy

Selecting the right industrial weigher is a critical decision that directly impacts your bagging line’s efficiency, accuracy, and profitability. As we have detailed, success hinges on matching the right technology to your material and ensuring seamless system integration for optimal performance. As a trusted manufacturer since 1978, we know that a precisely calibrated weigher doesn’t just fill bags-it protects your bottom line and your brand’s reputation.

Our commitment to reliability is built into every piece of our equipment, all proudly Made in the USA. We provide expert integration and dedicated field service support, acting as your long-term partner in productivity. Don’t leave this critical decision to chance. Unsure which weigher fits your operation? Consult the Bagger Professor for expert guidance. Invest confidently and let us help you build a more efficient and profitable bagging line today.

Frequently Asked Questions

What is the difference between an industrial weigher and a scale?

While both measure weight, their applications differ significantly. A scale typically provides a static measurement of an object placed upon it. An industrial weigher, however, is an automated system integrated into a production line. It is engineered to precisely dispense a target amount of product into a bag or container repeatedly and at high speed. This dynamic function is critical for ensuring consistent packaging, operational efficiency, and profitability in a bagging line.

How accurate are modern industrial weighers?

The accuracy of modern industrial weighers is exceptional, designed for minimal product giveaway and maximum consistency. Depending on the model and the product’s characteristics, our systems consistently achieve accuracies of +/- 0.5% to 0.1% of the target weight. For a 50 lb bag, this translates to an accuracy of just a few ounces. This level of precision is essential for maintaining quality control and protecting your bottom line from costly overfills.

What is the difference between a gross weigh and a net weigh bagger?

The key difference lies in when the product is weighed. In a gross weigh system, the product is weighed directly in the bag as it fills. This method is simpler and more cost-effective. A net weigh system weighs the product in a separate hopper before it is discharged into the bag. While the bag is being changed, the next batch is already being weighed, making net weighers significantly faster and more accurate for high-volume production lines.

How does my product’s bulk density affect weigher performance and speed?

A product’s bulk density directly impacts weigher performance and throughput. Lighter, less dense products require more volume to reach a target weight and may flow slower, potentially reducing bagging speed. Conversely, heavy, dense materials like sand or concrete mix flow quickly and occupy less space, allowing for faster fill rates. We engineer our systems to account for these variables, ensuring optimal performance and accuracy for your specific product.

Can a single industrial weigher be used for multiple different products?

Yes, a single industrial weigher can often handle multiple products, provided their flow characteristics are similar. Modern systems feature recipe storage, allowing for quick changeovers between pre-programmed product weights and flow rates. For applications involving dissimilar products or cross-contamination concerns, features like easy-to-clean contact surfaces are critical. We can help determine the most versatile and efficient weigher configuration for your operational needs.

What is a load cell and how does it work in a weigher?

A load cell is the core sensory component of a modern weigher. It is a highly precise transducer that converts the force of the product’s weight into a measurable electrical signal. This signal is sent to the weigher’s controller, which constantly monitors the reading. Once the signal indicates that the target weight has been reached in the weigh hopper or bag, the controller instantly closes the feed gate to ensure a precise and repeatable fill every time.

Recent Comments