Is your production line’s final stage a source of constant bottlenecks and frustration? Manual palletizing often leads to inconsistent stacks, workplace injuries, and high labor costs that directly impact your bottom line. This is where high-performance palletizing equipment transforms your operation, providing a reliable and efficient solution to these persistent challenges.

Making the move to automation requires a confident investment, and selecting the right system can feel complex. This comprehensive guide is designed to provide clarity and direction. We will walk you through the different types of automated palletizers, outline the key criteria for selecting the ideal system for your facility, and explore the tangible ROI you can expect. Our goal is to equip you with the knowledge to optimize your end-of-line process with unmatched performance and safety, ensuring you can invest with total confidence.

What is Palletizing Equipment and Why is it Essential?

In modern production and distribution environments, palletizing equipment refers to automated machinery engineered to stack goods or products onto a pallet in a predefined pattern. This technology stands in stark contrast to manual palletizing, a physically demanding process prone to inconsistency and human error. To understand the fundamentals of this machinery, it is helpful to explore what a palletizer is and its evolution from conventional to robotic systems. By automating the end of your production line, you replace a repetitive, high-risk task with a reliable, high-performance solution.

To see this principle in action, the following video demonstrates the core function of an automated system:

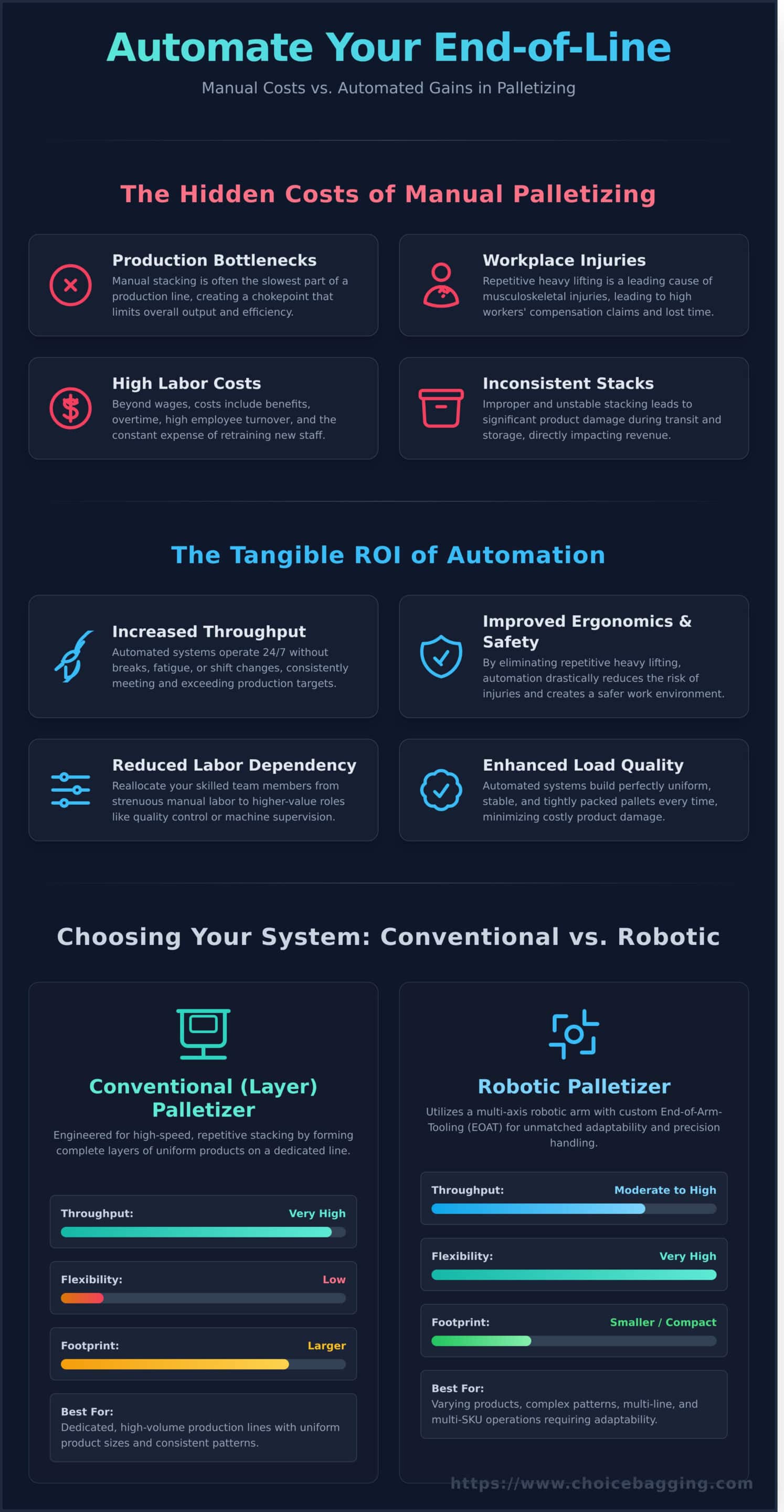

The primary drivers for adopting this technology are clear: speed, safety, and consistency. Manual stacking is often the slowest part of a production line, creating a bottleneck that limits overall output. Furthermore, the repetitive lifting of heavy items is a leading cause of musculoskeletal injuries in industrial settings. According to the U.S. Bureau of Labor Statistics, overexertion from motions like lifting is a primary source of workplace injuries. Automated systems directly address these critical business challenges with unmatched efficiency and reliability.

The True Cost of Manual Palletizing

Relying on manual labor for palletizing carries significant and often underestimated costs. Beyond the direct expenses of wages, benefits, and overtime for multiple workers, there are substantial indirect and operational costs. These include high workers’ compensation claims from injuries, increased employee turnover and retraining expenses, and financial losses from product damage due to improper stacking and subsequent shipping inefficiencies.

Key Benefits of Automated Palletizing

Investing in automated palletizing equipment delivers a powerful return by transforming your end-of-line operations. The advantages are tangible and directly impact your bottom line:

-

Increased Throughput: Robotic and conventional palletizers operate 24/7 without breaks, fatigue, or shift changes, consistently meeting or exceeding production targets.

-

Improved Ergonomics & Safety: By eliminating the need for repetitive heavy lifting, automation drastically reduces the risk of costly workplace injuries and creates a safer environment for your team.

-

Enhanced Load Quality: Automated systems build perfectly uniform, stable, and tightly packed pallets every time, minimizing product damage during transit and storage.

-

Reduced Labor Dependency: Automation allows you to reallocate skilled employees from strenuous manual labor to higher-value roles, such as quality control or machine supervision.

Types of Palletizing Equipment: Conventional vs. Robotic

Selecting the right automated palletizing equipment is a critical decision that directly impacts operational efficiency, throughput, and future scalability. The choice between conventional and robotic systems hinges on your specific application needs, including production speed, product variability, and available floorspace. Both technologies offer a significant upgrade over manual palletizing, which often struggles to meet production demands and adhere to established ergonomic guidelines for worker safety. For unique applications, hybrid systems can also be engineered to combine the high-speed layer forming of conventional machines with the precision of robotic handling.

| Feature | Conventional Palletizer | Robotic Palletizer |

|---|---|---|

| Throughput | Very High | Moderate to High |

| Flexibility | Low (Dedicated Lines) | Very High (Multi-Line, Multi-SKU) |

| Footprint | Larger | Smaller / More Compact |

| Best For | Uniform products, high-speed single lines | Varying products, complex patterns, multiple lines |

Conventional (Layer) Palletizers

Conventional palletizers, also known as layer palletizers, are engineered for one primary purpose: high-speed, repetitive stacking. These systems operate by receiving products from a conveyor, arranging them into a complete, pre-formed layer, and then placing that entire layer onto the pallet. This process is repeated with unmatched speed until the pallet is complete.

-

System Types: They are typically categorized as either high-level or low-level infeed, depending on the height at which products enter the machine. High-level systems offer the highest speeds, while low-level systems provide easier access for operators.

-

Pros & Cons: Their main advantage is superior throughput, making them ideal for dedicated, high-volume production lines with uniform product sizes. However, they require a larger footprint and offer minimal flexibility for pattern or product changes.

Robotic Palletizers

Robotic palletizers utilize a multi-axis robotic arm equipped with custom End-of-Arm-Tooling (EOAT) to pick and place products individually or in groups. This design provides a level of adaptability that conventional systems cannot match, making it a highly versatile piece of palletizing equipment.

-

System Operation: The robot’s EOAT is custom-designed for the specific product-be it bags, cases, pails, or cartons-ensuring secure and precise handling. The system can be easily programmed to build complex, interlocking patterns or switch between different product SKUs on the fly.

-

Pros & Cons: The primary benefits are superior flexibility and a smaller, more adaptable footprint. They are the ideal solution for multi-line operations, mixed-product pallets, and frequent changeovers. While their top speed may be lower than a dedicated conventional palletizer, their overall efficiency in complex applications is often far greater.

How to Choose the Right Palletizing System for Your Needs

Selecting the right palletizing equipment is a critical decision that directly impacts your operational efficiency and profitability. There is no one-size-fits-all solution; the ideal system is one that is precisely matched to your specific production environment. Viewing this process as an operational analysis rather than just a purchase ensures you invest confidently in a system built for long-term performance.

Before evaluating specific machines, a thorough internal assessment is essential. As your integration partner, we recommend asking the following key questions:

-

What is our current and projected production rate (cases, bags, or units per minute)?

-

What are the physical properties of the products we need to palletize (size, weight, stability)?

-

How many different SKUs and stacking patterns will the system need to handle per shift?

-

What is the available floor space for the equipment, including infeed, discharge, and safety guarding?

-

What are our growth projections for the next 5-10 years?

Answering these questions provides a clear framework for evaluating the critical factors that determine the best palletizing equipment for your line.

Factor 1: Production Speed and Throughput

Your required palletizing speed must match or exceed your line’s maximum output to prevent bottlenecks. Calculate your needs in cases or bags per minute. High-speed, dedicated lines often benefit from conventional palletizers built for raw speed. For operations with variable speeds or multiple product lines, robotic systems offer superior flexibility, adapting easily to changes in throughput without significant downtime.

Factor 2: Product Type and Pattern Complexity

The nature of your product is a primary consideration. Robotic palletizers equipped with custom End-of-Arm Tooling (EOAT) provide the versatility to handle bags, cases, pails, and mixed loads with precision. If your operation requires complex, interlocking stacking patterns for load stability, the programmability of a robotic arm is unmatched. Conventional systems excel with uniform case sizes and simple, repeatable patterns.

Factor 3: Facility Footprint and Layout

Available floor space is often a deciding factor. Robotic palletizing cells are typically more compact and can be configured to fit into tight spaces. However, it’s crucial to account for the entire work envelope, including infeed/discharge conveyors and safety systems. The complete cell must be designed to comply with federal machine guarding standards to ensure a safe and productive environment for your team.

Factor 4: Budget and Return on Investment (ROI)

Look beyond the initial purchase price to the total cost of ownership. A comprehensive ROI calculation should include labor savings, increased uptime, and reduced product damage. Also, factor in long-term costs such as maintenance requirements, spare parts availability, and energy consumption. A durable, reliable system with strong manufacturer support delivers a faster and more significant return on investment.

Integrating Palletizing Equipment into a Complete System

Investing in high-performance palletizing equipment is a critical step toward automation, but it is only one piece of a much larger puzzle. For maximum efficiency and reliability, the palletizer must be seamlessly integrated into a complete end-of-line packaging system. Each component, from product filling to the final wrapped pallet, must work in perfect harmony.

Effective integration ensures a smooth, continuous flow of product, minimizes bottlenecks, and prevents costly downtime. The key to this success is ensuring all upstream and downstream components can communicate and operate as a single, cohesive unit. Let’s trace the product’s journey to understand the necessary components.

Upstream Considerations: Getting Product to the Palletizer

Before a product can be palletized, it must be properly prepared and transported. This stage begins with equipment like case packers or bag fillers that ready the product for handling. From there, reliable bag handling conveyors are essential for creating a consistent and predictable flow. These systems manage product orientation, pacing, and accumulation, ensuring each item arrives at the palletizer in the correct position and at the right time for stacking.

The Palletizing Cell: Core Components

The palletizing cell is the heart of the operation where the load is built. While the robotic or conventional palletizer is the central component, it relies on several support systems to function automatically. These essential elements work together to prepare for and execute the stacking pattern:

-

Pallet & Slip Sheet Dispensers: Automatically position empty pallets and place tier sheets between layers for load stability.

-

The Palletizer: The primary machine that executes the pre-programmed stacking patterns with precision and speed.

-

Safety Features: A non-negotiable part of any cell, including safety fencing, light curtains, and area scanners to protect personnel during operation.

Downstream Systems: Securing the Load

Once a pallet is fully stacked, its journey is not over. Downstream systems take over to secure the load and prepare it for warehousing or shipment. Discharge conveyors move the completed pallet away from the cell and into the next stage, which typically involves automatic stretch wrappers. This equipment tightly wraps the pallet in film, providing critical stability and protection. Finally, the pallet may pass through an automated labeler or weigh station before being transported by forklift to its destination.

Ensuring every one of these components functions as part of a unified system is the key to unlocking true operational efficiency. At Choice Bagging Equipment, we don’t just sell machines; we design and integrate complete, reliable systems built to perform.

Finding the Right Partner for Palletizer Integration and Support

Selecting the right robotic palletizer is only half the equation. The success of your automation project-and its long-term return on investment-depends heavily on the partner you choose to design, integrate, and support it. A machine is only as effective as the expertise behind it. Look beyond specifications and focus on the provider’s experience, engineering capability, and commitment to your operational success.

As a US-based manufacturer with decades of experience, we understand that purchasing palletizing equipment is a significant capital investment. The right partner doesn’t just sell you a robot; they deliver a comprehensive, reliable solution engineered to perform for years to come. This partnership is the key to maximizing uptime, efficiency, and profitability.

Expert System Design and Engineering

A true integration partner analyzes your entire production line, from infeed to wrapping, to design a system that solves your specific challenges. We consider your facility layout, product types, and throughput goals to engineer a custom solution. Choice Bagging Equipment offers comprehensive robotic palletizing systems designed for unmatched reliability and seamless integration into your existing operations.

Installation, Commissioning, and Training

Proper implementation is critical for performance and safety. Our process ensures your system is set up for success from day one. This includes:

-

Professional Installation: Our technicians ensure all components are installed correctly and integrated with your upstream and downstream equipment.

-

Thorough Commissioning: We rigorously test and validate the system to confirm it meets all performance and safety standards before handover.

-

Operator Training: We empower your team with the knowledge to operate and maintain the equipment safely and efficiently.

Long-Term Reliability and Support

Your relationship with your provider shouldn’t end after installation. Ongoing support is essential for maintaining peak performance. We ensure your investment is protected with readily available spare parts and access to expert technicians for maintenance and troubleshooting. Our dedicated field service team is committed to ensuring your palletizing equipment keeps your line running with minimal downtime.

To invest confidently in a solution built for lasting performance, it’s time to work with a partner you can trust. Contact Choice Bagging Equipment today to discuss your automation goals.

Invest Confidently in Your Automated Future

Automating your end-of-line operations is a critical step toward achieving greater efficiency, improving worker safety, and increasing overall throughput. As we’ve explored, the key to a successful transition lies not just in understanding the capabilities of conventional and robotic systems, but in carefully selecting a solution tailored to your unique products, line speed, and facility layout. The right palletizing equipment is a powerful investment, but its ultimate performance and ROI depend on expert integration and reliable, long-term support from a partner you can trust.

As a trusted manufacturer of durable, American-made equipment since 1978, Choice Bagging Equipment is more than a supplier-we are your long-term partner in performance. Our team provides comprehensive consultation, expert integration, and dedicated field service support to ensure your system delivers from day one and for decades to come. Take the next step toward a more productive and profitable future. Contact our experts to design your automated palletizing solution.

Frequently Asked Questions About Palletizing Equipment

What is the typical ROI for palletizing equipment?

The return on investment for palletizing equipment is typically realized within 12 to 24 months, though this varies with application specifics. Key factors influencing ROI include reduced labor costs, increased throughput, and the elimination of injuries associated with manual stacking. Automation also improves load consistency, which minimizes product damage during transit. A thorough analysis of your operational costs and production goals will provide a precise projection for your facility.

How much floor space is required for a robotic palletizer?

The footprint for a robotic palletizer depends on the system’s complexity. A simple, single-line cell with appropriate safety guarding can fit within a 10’ x 12’ area. However, more advanced systems integrating multiple infeed conveyors, pallet dispensers, and stretch wrappers will require a larger dedicated space. We engineer each system to maximize performance and safety within the constraints of your plant layout, ensuring an efficient and practical fit.

Can palletizing equipment handle different product sizes on the same line?

Yes. Modern robotic systems are engineered for flexibility. With advanced vision systems and versatile End-of-Arm Tooling (EOAT), a single palletizer can reliably handle various product types, sizes, and weights. Pre-programmed stacking patterns allow for automatic and seamless changeovers between different SKUs. This capability delivers the high performance and efficiency required for today’s dynamic production environments with diverse product mixes.

What kind of maintenance does automated palletizing equipment require?

Our automated palletizing equipment is built for durability and requires minimal routine maintenance to ensure long-term reliability. Standard procedures include periodic inspections, lubrication of mechanical components, and checks on sensor alignments as outlined in the service manual. Following the manufacturer’s recommended preventative maintenance schedule is the most effective way to guarantee decades of consistent performance and maximize your operational uptime.

How do you ensure safety around robotic palletizing cells?

Operator safety is a non-negotiable priority in every system we design. Our robotic cells meet or exceed all current OSHA and RIA safety standards through a multi-layered approach. This includes robust physical guarding, safety-rated door interlocks, and advanced presence-sensing devices like light curtains or area scanners. These components work together to create a secure environment, immediately stopping all robotic motion if a safety zone is entered.

What is End-of-Arm Tooling (EOAT) and why is it important?

End-of-Arm Tooling (EOAT) is the custom gripper attached to the robot’s arm that makes direct contact with your product. Its design is critical to the system’s overall performance and reliability. Whether using vacuum cups for cases, clamps for bags, or a specialized fork tool, the EOAT must be engineered to handle your product securely and consistently without causing damage. The right EOAT is fundamental to achieving dependable, high-speed operation.

Recent Comments