If the acronym ‘VFFS’ seems more like a complex code than a packaging solution, you are not alone. For many businesses looking to scale their operations, understanding the core technology behind automated bagging is the first critical step toward greater efficiency and reliability. A vertical form fill seal machine is a cornerstone of modern packaging, but deciphering its process and determining if it’s the right fit for your product line requires clear, expert guidance. Making the wrong choice can lead to costly downtime and inefficiency, while the right system can transform your production capabilities.

In this complete guide, we will demystify the entire process. We will break down exactly how a VFFS machine operates, from the initial film roll to the final sealed bag. You will gain a clear understanding of its key components, learn the difference between intermittent and continuous motion, and confidently identify whether this high-performance technology is the ideal solution for your specific products and production goals. Consider this your definitive resource for making an informed investment in your company’s future.

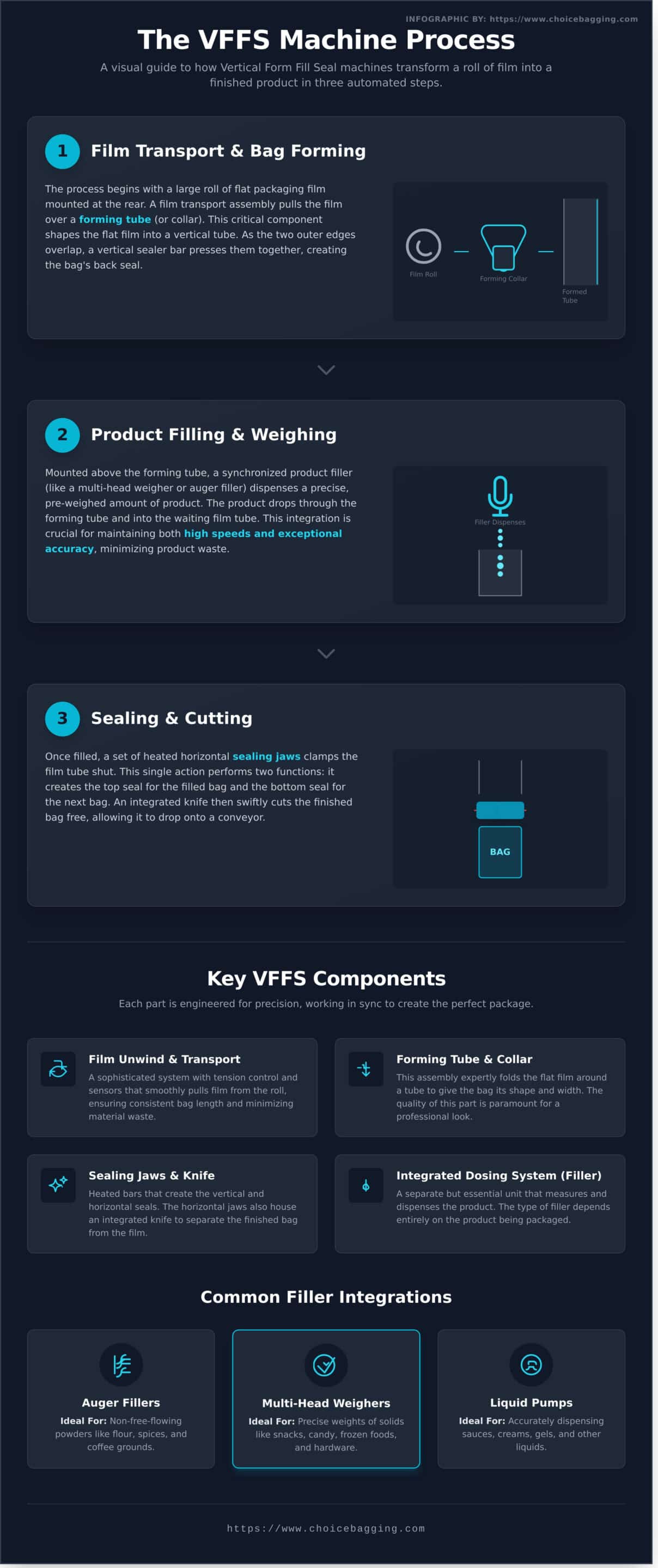

How a Vertical Form Fill Seal Machine Works: The 3 Core Steps

At its core, a vertical form fill seal machine is an engineering marvel designed for one primary purpose: to provide unparalleled efficiency in packaging. This automated system transforms a single roll of flat packaging film into finished, filled, and sealed bags in one seamless, continuous motion. The entire process follows a logical top-to-bottom path, making it an ideal solution for high-speed packaging of a wide range of consumer goods, from coffee grounds and snack foods to powders and liquids.

To visualize this highly engineered process, the following animation provides a clear, step-by-step breakdown:

This seamless operation is built on three distinct, perfectly synchronized stages that ensure high performance and reliability.

Step 1: Film Transport and Bag Forming

The process begins with a large roll of flat packaging film, which is mounted at the rear of the machine. A series of rollers, called the film transport assembly, precisely pulls the film into the system. As the film crests the top, it is fed over a forming tube or collar. This critical component shapes the flat film into a vertical tube, and as the two outer edges of the film overlap, a vertical sealer bar presses them together to create the back seal of the bag. This foundational mechanism is a key feature of the modern Vertical form fill sealing machine.

Step 2: Product Filling and Weighing

Mounted directly above the forming tube is a product filler, such as a multi-head weigher for solids or an auger filler for powders. This device is synchronized with the machine’s operation to dispense a precise, pre-determined amount of product down through the forming tube and into the waiting film tube. This integration is crucial for maintaining both high speeds and exceptional accuracy, ensuring consistent package weights while minimizing costly product waste.

Step 3: Sealing and Cutting

Once the product has been dispensed, a set of heated horizontal sealing jaws clamps shut across the film tube. This single action performs two critical functions simultaneously: it creates the top seal for the filled bag below and the bottom seal for the next bag to be filled. An integrated knife, housed within the jaws, then swiftly cuts the finished bag free, allowing it to drop onto a take-away conveyor for packing and distribution. The cycle then repeats with unmatched speed and reliability.

The Key Components of a VFFS Machine Explained

To fully appreciate the efficiency and reliability of a vertical form fill seal machine, it is essential to understand its core components. Each part is engineered for precision and durability, working together in a synchronized system to transform a flat roll of film into a perfectly sealed and filled package. This foundational knowledge is critical for both operators aiming for peak performance and buyers making a confident investment in their packaging line.

Film Unwind and Transport System

The process begins here, where a large roll of packaging film is mounted onto a spindle assembly. A sophisticated tension control system ensures the film feeds smoothly, preventing breaks and wrinkles. From there, powered drive belts grip the film, pulling it through the machine with exacting precision. Advanced sensors continuously track the film’s position, guaranteeing consistent bag length and minimizing material waste-a critical factor for operational efficiency.

Forming Tube and Collar

This assembly is where the flat film takes its three-dimensional shape. As the film is pulled down over the forming collar, it is expertly folded around the forming tube to create the bag. The design of the collar dictates the final width of the bag, and different tube sets are used for various package sizes. The quality and precision of this component are paramount for producing consistent, professional-looking bags cycle after cycle.

Sealing Jaws and Knife Assembly

Once the bag is formed and filled, the sealing jaws complete the package. A heated vertical seal bar creates the longitudinal seal down the back of the bag. Then, a set of horizontal jaws performs two critical actions simultaneously: it creates the top seal of the filled bag and the bottom seal of the next bag. An integrated knife then cleanly separates the finished bag from the film web in one efficient motion.

Integrated Dosing System (Filler)

While technically a separate piece of equipment, the dosing system, or filler, is essential to the operation of any vertical form fill seal machine. The VFFS machine creates the bag, but the filler is what ensures an accurate amount of product goes inside. Choosing the correct filler is critical for performance and depends entirely on your product. Common integrations include:

-

Auger Fillers: For non-free-flowing powders like flour or spices.

-

Multi-Head Weighers: For precise weights of solids like snacks, candy, and frozen foods.

-

Liquid Pumps: For accurately dispensing sauces, creams, and other liquids.

Common Applications and Bag Styles for VFFS

The performance and efficiency of a vertical form fill seal machine are best demonstrated by its incredible versatility. These systems are engineered to handle a wide range of product viscosities, densities, and shapes, making them a cornerstone for high-volume packaging operations across numerous industries. From food and beverage to pharmaceuticals and hardware, VFFS technology delivers consistent, reliable results. Understanding the ideal product types and available bag styles is the first step in determining if this equipment is the right investment for your production line.

Ideal Products for VFFS Packaging

The robust design of a VFFS machine allows it to package everything from delicate snacks to dense liquids with high precision and reliability. This adaptability makes it a valuable asset for producers who need to maintain product integrity while maximizing throughput. Common applications include:

-

Snack Foods: Fragile products like potato chips, pretzels, nuts, and popcorn are perfectly suited for VFFS. The gentle product handling and accurate weighing systems ensure minimal breakage and consistent bag weights.

-

Powders & Granules: The precise dosing capabilities of auger fillers integrated with VFFS are ideal for coffee, sugar, spices, flour, and protein powders, minimizing costly product waste.

-

Frozen Foods (IQF): Built to operate in cold, damp environments, VFFS machines are the standard for packaging Individually Quick Frozen (IQF) vegetables, fruits, and seafood while maintaining food safety standards.

-

Liquids & Pastes: When equipped with the proper liquid or piston filler, these systems can reliably package sauces, soups, dressings, and other viscous products into durable, leak-proof bags.

Popular Bag Styles Created

Beyond product compatibility, the ability to create various bag styles on a single machine provides significant operational flexibility and enhances product marketability. A high-performance VFFS system can be quickly changed over to produce different formats, allowing you to adapt to consumer demands. The most effective styles include:

-

Pillow Bag: The most economical and widely used style, formed from a simple tube of film with top, bottom, and vertical seals. Its simplicity ensures high-speed production and cost-efficiency.

-

Gusseted Bag: Featuring side gussets that expand when filled, this style offers more internal volume for the same film width and a more structured, block-like shape than a standard pillow bag.

-

Block Bottom Bag: Also known as a flat bottom bag, this premium style has a square, flat base that allows it to stand upright and unsupported on retail shelves, providing excellent brand presentation.

-

Sachet/Stick Pack: These small, narrow pillow bags are the go-to format for single-serve applications. They are perfect for sugar packets, instant coffee sticks, and condiment portions, offering convenience to the end-user.

VFFS vs. Other Bagging Machines: Which Do You Need?

Selecting the right bagging technology is a critical decision that directly impacts your production line’s efficiency, cost-effectiveness, and reliability. While a vertical form fill seal machine offers unmatched speed for certain applications, it’s one of several high-performance solutions. Understanding the core strengths of each system ensures you invest in equipment that aligns perfectly with your product, bag type, and operational goals.

When to Choose VFFS: Speed and Small Pouches

A vertical form fill seal machine is the premier choice for high-speed, high-volume packaging of consumer-sized products. It excels with weights typically under 10 lbs (approx. 5 kg). The system creates, fills, and seals pouches on the fly from a single roll of flexible film, making it extremely efficient for retail goods like snacks, coffee, or powders that require high-quality printed packaging.

When an Open Mouth Bag Filler is the Better Choice

For larger, industrial applications, an open mouth bagger is often the superior solution. Unlike VFFS, this equipment is engineered to fill pre-made bags, handling weights from 10 to 110 lbs. Its robust design makes it ideal for abrasive or bulky products like aggregates, animal feed, or chemicals. Explore our durable open mouth bagging machines for these larger-scale applications.

The Role of Valve Bag Fillers for Dense Powders

When packaging fine, dense powders that require compaction, a valve bag filler provides unmatched performance. This specialized machine uses bags with a built-in, self-closing valve to create tightly packed, brick-like bags. This method minimizes dust and results in highly stable, square bags that are perfect for stacking on pallets. Learn about our high-accuracy valve bag fillers for materials like cement, stucco, and flour.

Completing the Line with Automation

No bagging machine operates in a vacuum. Whether you choose a VFFS, open mouth, or valve bagger, it is the first step in a fully automated end-of-line system. Filled bags move via conveyors to be checked, conditioned, and stacked for shipment. Integrating this equipment with downstream automation is key to maximizing throughput and reducing labor costs. Discover how robotic palletizing systems can boost your line’s overall efficiency.

Key Factors to Consider When Evaluating Packaging Machinery

Selecting the right packaging equipment is a significant investment in your operational efficiency and future growth. While the benefits of a vertical form fill seal machine are clear, a successful purchase depends on a thorough evaluation of your specific production needs. Asking the right questions upfront ensures you acquire a solution built for performance, reliability, and long-term value. This checklist empowers you to make a confident decision.

Production Speed and Required Throughput

Your machine’s output must align perfectly with your production targets. Before engaging with suppliers, define your required throughput to ensure the equipment can meet both current and future demand. Vague goals can lead to an underperforming line or an unnecessary expense.

-

Target Bags Per Minute (BPM): Establish a clear, non-negotiable BPM target for your operation.

-

Motion Type: Understand the difference between intermittent motion (ideal for lower speeds and precision) and continuous motion (built for high-speed, high-volume production).

-

Operational Uptime: Factor in realistic time for film roll changes, product changeovers, and routine maintenance when calculating your true throughput.

Product and Packaging Material Compatibility

A machine is only as effective as its ability to handle your specific product and packaging materials. Incompatibility can cause constant jams, poor seal quality, and wasted product. Confirm that all product-contact surfaces meet required standards, especially for food-grade applications. Discussing material specifics, such as film type, thickness, and sealant layers, with your equipment manufacturer is a critical step to guarantee reliable performance.

Footprint, Integration, and Future Scalability

Your new equipment must fit seamlessly into your existing production line and physical plant space. Measure your available floor space carefully, accounting for operator access and maintenance areas. Plan how the machine will integrate with upstream and downstream equipment like fillers, checkweighers, and conveyors. Most importantly, choose a machine that supports your growth. Discussing scalability ensures the vertical form fill seal machine you invest in today will not limit your potential tomorrow. A true equipment partner will help you plan for the future.

Find Your Ideal Packaging Solution with an Experienced Partner

Understanding the core functions, key components, and diverse applications of a vertical form fill seal machine is the first step toward optimizing your packaging operations. As this guide has detailed, these systems deliver exceptional speed and efficiency, but choosing the right configuration for your specific product and bag style is critical for achieving long-term reliability and performance. The right equipment is more than a purchase; it is a strategic investment in your company’s productivity and growth.

Making that investment confidently requires a partner you can trust. With expert engineering support since 1978 and a commitment to high-quality equipment that is proudly Made In The USA, we are your partner in packaging line integration. We provide solutions built for durability and unmatched performance, ensuring you receive a machine engineered to meet your exact specifications and deliver a superior return on investment.

Ready to enhance your efficiency and secure a dependable bagging system? Consult our experts to find the right bagging solution for your product. We look forward to building a durable, high-performance system for your production line.

Frequently Asked Questions

What is the main difference between a VFFS and an HFFS machine?

The primary difference is the machine’s orientation and product flow. A Vertical Form Fill Seal (VFFS) machine uses gravity to drop products into a vertically formed bag, making it ideal for loose, granular, or liquid items like snacks, coffee, or powders. A Horizontal Form Fill Seal (HFFS) machine packages products horizontally, which is better suited for single, solid items like candy bars, baked goods, or medical devices that cannot be dropped.

What does ‘intermittent motion’ vs. ‘continuous motion’ mean in VFFS?

This describes how the machine pulls and seals the packaging film. Intermittent motion machines stop the film advancement to make each cross seal, offering reliable performance for a wide range of applications. Continuous motion machines seal the film while it is still moving, enabling significantly higher speeds and greater throughput. The choice depends entirely on your production rate requirements, with continuous motion being the solution for high-volume operations where efficiency is paramount.

How much does a vertical form fill seal machine typically cost?

The cost of a vertical form fill seal machine varies widely based on its capabilities, typically ranging from $30,000 to over $200,000. Key factors influencing the price include the required speed (bags per minute), the complexity of the integrated filling system (e.g., auger vs. multi-head weigher), and customizations for different bag styles. Investing in a high-quality machine ensures long-term reliability, performance, and a superior return on your investment.

What kind of maintenance does a VFFS machine require?

Consistent, preventative maintenance is crucial for ensuring peak performance and durability. Daily tasks include cleaning product contact parts and sealing jaws to prevent buildup. Weekly checks should focus on inspecting wear parts like knives, belts, and sealing bands for signs of fatigue. Following a manufacturer-recommended schedule for lubrication and calibration will guarantee your machine operates with unmatched reliability for decades, protecting your investment and minimizing downtime.

Can one VFFS machine handle multiple bag sizes and products?

Yes, a key benefit of a modern vertical form fill seal machine is its operational flexibility. By using quick-change parts, such as different forming tubes and collars, a single machine can be configured to produce a variety of bag widths and lengths. When paired with an appropriate filler, it can also handle different products. This versatility allows you to adapt to changing market demands efficiently without investing in entirely new production lines.

How accurate are the filling systems used with VFFS machines?

The filling accuracy is determined by the integrated filler, not the VFFS machine itself. High-quality filling systems deliver exceptional precision. For example, multi-head weighers for solid products and auger fillers for powders can consistently achieve accuracies of +/- 1% or better. This level of precision minimizes product giveaway, reduces waste, and directly improves your bottom line, ensuring an efficient and profitable packaging process.

What are the common challenges when operating a VFFS machine?

Common operational challenges include improper film tracking, inconsistent seal quality (due to incorrect temperature or pressure), and product bridging in the filler funnel. These issues are almost always preventable with proper machine setup, operator training, and the use of high-quality film. A well-built machine with easy-to-use controls and dependable support from your manufacturing partner is essential for minimizing these challenges and maintaining consistent, efficient production.

Recent Comments