Stepping into the world of automated packaging can feel overwhelming. With a landscape of complex terminology and a wide array of equipment options, it’s difficult to know where to begin or which solution will deliver the performance and reliability your operation demands. For many businesses looking to improve efficiency, the answer lies in a high-performance vffs machine. This technology is a cornerstone of modern packaging, but understanding its true potential requires a clear, straightforward explanation of its function and benefits.

This comprehensive guide is designed to cut through the complexity. We will break down exactly how a Vertical Form Fill Seal machine works, from its key components to its operational process. You will gain a clear understanding of its significant advantages, explore its most common applications, and learn the essential factors to consider before making an investment. By the end of this article, you will have the knowledge to confidently assess if VFFS technology is the right choice for your production line and engage in productive conversations with equipment suppliers.

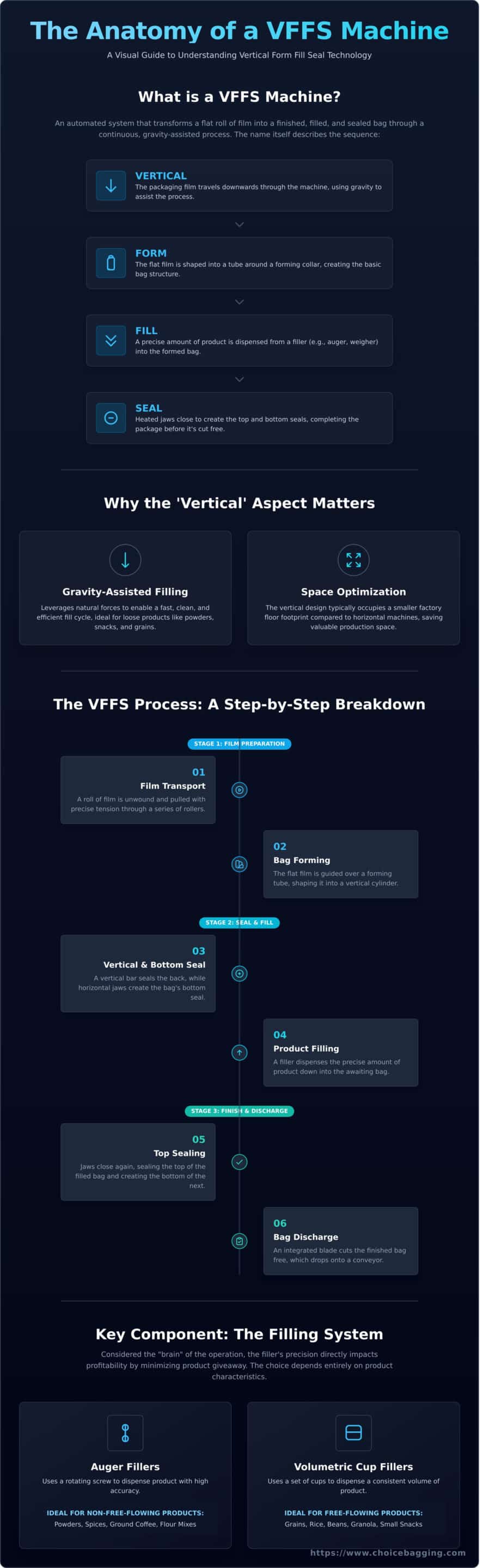

What is a Vertical Form Fill Seal (VFFS) Machine?

A Vertical Form Fill Seal (VFFS) machine is a high-performance automated packaging system that creates flexible bags from a flat roll of film, fills them with product, and seals them, all in a continuous vertical motion. The name itself describes the core function in sequence: the film travels Vertically, is Formed into a bag, is Filled with product, and is then securely Sealed. This integrated technology is a cornerstone of modern packaging lines, engineered to deliver unmatched efficiency, speed, and consistency for a wide range of products.

To see this efficient process in action, the following animation provides a clear overview:

Unlike Horizontal Form Fill Seal (HFFS) machines, which are often used for single, solid items that must be placed into a package, a VFFS system is ideal for products that can be dropped or dispensed. It also differs significantly from pre-made pouch fillers, which handle bags that are already formed. The primary advantage of a vffs machine is its ability to automate the entire bag creation and filling process from raw material, maximizing production throughput and reducing operational costs.

The Core Principle: From a Flat Roll to a Finished Bag

The operation begins with a single, large roll of flexible packaging film. The machine pulls this flat material over a forming tube, shaping it into a cylinder and creating a vertical back seal. As detailed by the operational overview of a Vertical form fill sealing machine, the system then makes a bottom horizontal seal, fills the bag with a precise amount of product, and completes the top seal. This final top seal simultaneously creates the bottom seal for the next bag in the sequence. This all-in-one process transforms a simple roll of film into a finished, retail-ready product with exceptional reliability.

Why is the ‘Vertical’ Aspect Important?

The vertical orientation is a critical design feature that leverages gravity to its advantage. This natural assistance makes the filling process highly efficient for dispensing loose items such as powders, grains, snacks, coffee, and even liquids. By allowing the product to drop directly into the formed bag, it ensures a fast and clean fill cycle. Furthermore, this vertical design typically results in a smaller factory floor footprint compared to its horizontal counterparts, optimizing valuable production space.

How Does a VFFS Machine Work? The Step-by-Step Process

At its core, a Vertical Form Fill Seal (VFFS) machine performs a highly synchronized sequence of mechanical actions to create, fill, and seal a bag from a flat roll of film. This automated cycle is designed for high-speed production and unmatched efficiency. Understanding this step-by-step process reveals the engineering that makes this equipment an asset in any packaging operation.

The entire packaging cycle can be broken down into six primary actions, often grouped into three distinct stages.

Steps 1 & 2: Film Transport and Bag Forming

The process begins with a large roll of packaging film mounted on a spindle at the rear of the machine. A series of rollers, known as the film transport system, unwinds the film and maintains precise tension to ensure it feeds smoothly without wrinkles or slipping. The flat film is then pulled over a forming tube (or forming collar), which shapes the flat sheet into a vertical tube with the two outer edges overlapping.

Steps 3 & 4: Sealing and Product Filling

As the film is shaped into a tube, a vertical sealing bar presses against the overlapping edges, using heat and pressure to create the bag’s back seam. Next, a pair of horizontal sealing jaws comes together to create the bottom seal of the first bag. At this moment, a filler—such as an auger filler for powders or a multi-head weigher for snacks—accurately dispenses a pre-measured amount of product down through the forming tube and into the waiting bag.

Steps 5 & 6: Top Sealing and Discharge

Once the product has settled in the bag, the film is pulled down to the specified bag length. The horizontal sealing jaws then close again. This single action performs two critical tasks simultaneously: it creates the top seal of the filled bag while also forming the bottom seal of the next bag in the tube. A sharp blade, typically integrated into the jaw assembly, cuts the finished bag free, which is then discharged onto a conveyor belt or into a collection bin.

This entire, seamless cycle repeats with remarkable speed and precision, making the vffs machine a cornerstone of modern automated packaging.

Key Components of a VFFS Machine Explained

To truly appreciate the efficiency and value of a Vertical Form Fill Seal machine, it is essential to understand its core components. A high-performance vffs machine operates not as a single unit, but as a synchronized system of precision-engineered assemblies. Understanding how these parts work together empowers you to select equipment built for durability and unmatched operational reliability.

Each component plays a critical role in transforming raw materials into a finished, market-ready product. Investing in quality at each stage ensures higher output, less waste, and a more dependable packaging line.

The Filling System (The ‘Brain’ of the Operation)

The filler is responsible for accurately measuring and dispensing your product into each bag. The choice of filler is dictated entirely by the product’s characteristics, and its precision directly impacts profitability. A high-quality filling system is non-negotiable for minimizing product giveaway and ensuring consistency.

- Auger Fillers: Utilize a rotating screw to dispense non-free-flowing products with high accuracy. They are the industry standard for powders, spices, and fine ground coffee.

- Volumetric Cup Fillers: Use a set of cups to dispense a consistent volume of product. This method is ideal for free-flowing, granular items like rice, beans, and small snack foods.

- Multi-Head Weighers: Employ multiple weigh buckets to combine and achieve a highly precise target weight. They deliver superior accuracy for high-value, irregular-shaped products such as candy, nuts, and frozen foods.

Film Transport and Forming Assembly

This assembly is the mechanical heart of the machine, responsible for handling the packaging film and shaping the bag. The reliability of these components is crucial for preventing film waste and production downtime.

- Film Unwind Spindle: Securely holds the master roll of flat packaging film, ensuring it feeds into the system smoothly and with proper tension.

- Forming Tube/Collar: As the film is pulled from the roll, it passes over this precisely engineered component, which shapes the flat material into a vertical tube. The quality of the forming tube directly affects the final appearance of the bag.

- Drive Belts: These specialized belts grip the film tube and pull it downward through the machine with exacting precision, controlling the bag length for consistent results.

Sealing and Cutting Jaws

The final stage of the packaging process is performed by the jaw assembly, which creates the secure seals that protect your product. The durability and design of these jaws are paramount for creating strong, attractive seals on every bag.

- Heated Sealing Jaws: A set of horizontal jaws that clamp together with heat and pressure to create the top seal of one bag and the bottom seal of the next. A vertical sealer creates the back seal of the bag.

- Jaw Drive System: This mechanism controls the jaw movement. Intermittent motion systems pause the film for sealing, while continuous motion systems seal while the film is moving, enabling higher production speeds.

- Integrated Knife: A sharp blade, typically housed within the sealing jaw assembly, that cleanly separates each completed bag from the film tube.

Common Applications: What Products Are Packaged with VFFS Machines?

The true measure of a technology’s value is its real-world impact. The versatility of the vffs machine means its output is visible on nearly every shelf in a grocery store, warehouse, or retail environment. By integrating with different filler and weighing systems, these machines can be configured to handle an exceptionally wide range of products across numerous industries.

Understanding these applications helps businesses see how this technology can be adapted to their specific production needs, ensuring efficiency, accuracy, and product integrity.

Dry Goods: Powders and Granules

For packaging free-flowing and non-free-flowing dry products, a VFFS system provides a clean and efficient solution. To achieve precise, repeatable dosing, the machine is integrated with an auger filler, which dispenses product by volume. Common examples include:

- Coffee grounds and whole beans

- Flour, sugar, and baking mixes

- Spices and seasonings

- Protein powder and nutritional supplements

It is important to note that while VFFS is ideal for retail-sized bags, for larger, industrial-scale quantities, valve bag fillers are often a better solution due to their high-volume capacity.

Solid Products and Snack Foods

The snack food and frozen goods industries rely heavily on VFFS technology for its speed and precision. For these piece products, the vffs machine is paired with a multi-head weigher to ensure each bag meets its target weight with minimal product giveaway. Many systems also use Modified Atmosphere Packaging (MAP), flushing bags with nitrogen to extend shelf life and protect fragile items. Products include:

- Potato chips, pretzels, and popcorn

- Nuts, seeds, and trail mix

- Candies and gummies

- Individually Quick Frozen (IQF) fruits and vegetables

Liquids and Viscous Products

Packaging liquids and semi-liquids requires specialized engineering to guarantee a clean fill and a secure seal. These VFFS systems are equipped with robust liquid pumps and specialized nozzles to manage product flow without drips or splashes. The sealing process is critical, creating strong, leak-proof bags to ensure product safety and prevent costly spills. Applications include:

- Sauces, dressings, and soups

- Ketchup and mustard

- Shampoo and conditioner

- Industrial cleaning fluids

Key Benefits of Integrating a VFFS System

While the technical specifications of a vertical form fill seal machine are impressive, their true value is measured by the tangible return on investment they deliver to your operation. Integrating an automated VFFS system is a strategic decision that directly impacts efficiency, cost-control, and product quality, providing a clear path to increased profitability and scalability.

Investing in this technology addresses the core challenges of modern production, transforming your packaging line from a cost center into a competitive advantage.

Increased Production Speed and Throughput

Manual or semi-automated packaging lines are often limited to just a few bags per minute, creating a bottleneck that restricts growth. A vffs machine shatters this limitation, with intermittent motion models producing 30-80 bags per minute (BPM) and high-speed continuous motion systems capable of exceeding 100 BPM. This dramatic increase in throughput allows you to meet growing customer demand and take on larger contracts without a proportional increase in labor costs.

Reduced Labor and Material Costs

Automation is a direct path to lower operational expenses. A VFFS system consolidates forming, filling, and sealing into one seamless process, significantly reducing the need for manual bag handling. This leads to substantial savings in labor costs and minimizes the risk of human error. Key financial benefits include:

- Lower Film Costs: Using rollstock film is significantly more cost-effective than purchasing and managing an inventory of pre-made bags.

- Reduced Product Giveaway: Highly accurate fillers ensure each bag is filled to the precise target weight, eliminating costly overfills and reducing product waste.

Improved Accuracy, Consistency, and Versatility

Automated systems deliver a level of precision that manual processes cannot match. Every bag produced has a consistent, professional appearance and a reliable, high-integrity seal, protecting your product and enhancing your brand’s reputation for quality. Modern systems also offer exceptional versatility, with quick-changeover capabilities that allow you to efficiently run different products, bag styles, and film types on a single machine. This flexibility ensures your investment continues to provide value as your product lines evolve.

Understanding these benefits is the first step toward finding the right packaging solution. To see how this technology can be applied to your specific needs, it is crucial to consult with an experienced equipment partner.

Is a VFFS Machine Right for Your Business? Next Steps

Understanding the components and operation of a vertical form fill seal machine is the first step. The next is determining if this technology is the optimal solution for your specific application. A successful integration depends on a thorough analysis of your product, packaging, and production goals. Use the following points as a starting checklist to guide your evaluation process.

Evaluating Your Product and Film

The right equipment configuration starts with your product. A careful review of its unique properties ensures reliable performance and high-quality final packaging. Before proceeding, define these key factors:

- Product Characteristics: Is your product a free-flowing powder, a granular solid, a fragile item, or a liquid? Factors like dustiness, stickiness, and piece size will dictate the ideal filler and machine setup.

- Packaging Film: Determine the required film material, such as polyethylene (PE), polyester (PET), or a specialized laminate, based on your product’s barrier and shelf-life requirements.

- Bag Style: Identify the necessary bag type for your market, whether it’s a standard pillow bag, a gusseted bag for more volume, or a premium flat-bottom bag for stand-up shelf presence.

Considering Your Production Environment

A VFFS machine must function as an integral part of your larger packaging line. Consider its role in your overall workflow, from how product is fed into the machine to how finished bags are handled. Key considerations include required output speed (bags per minute or hour) and seamless integration with upstream weighers and downstream equipment. For instance, you must plan how finished bags will be transferred to a checkweigher, case packer, or an automated robotic palletizing system.

Partnering with an Equipment Expert

Making the right capital investment requires more than just reading specifications. The most critical step is to consult with an experienced equipment manufacturer who acts as your partner. A true partner analyzes your complete operational needs to recommend a solution engineered for durability and long-term performance. It is important to remember that a vffs machine is just one of many bagging technologies available.

At Choice Bagging Equipment, we have provided high-quality, American-made bagging solutions since 1978. Our team is ready to help you navigate your options and find the system that delivers unmatched reliability for your business. Contact us today for an expert consultation.

Invest Confidently in Your Packaging Automation

Vertical form fill seal technology offers a powerful, efficient, and reliable method for automating your packaging line. By integrating the forming, filling, and sealing processes into one seamless operation, these systems drive significant gains in productivity and ensure consistent, high-quality results. Understanding how this technology works is the first step toward transforming your production capabilities and scaling your business for future growth.

Making the right equipment choice is a critical investment. As a trusted manufacturer of high-performance bagging systems since 1978, Choice Bagging Equipment delivers unmatched reliability and durability in every machine we build. All our systems are proudly Made in the USA, and we are more than just a supplier; we are your long-term partner, providing expert integration and dedicated field service support to ensure your success.

If you are ready to determine if a vffs machine is the right solution for your operation, our team is here to help. Contact our experts to discuss your packaging automation needs. Let’s build a more efficient and profitable future for your business together.

Frequently Asked Questions

What is the difference between a VFFS and an HFFS machine?

The primary difference lies in the orientation of the packaging process. A VFFS (Vertical Form Fill Seal) machine uses gravity to drop products into a vertically formed bag, making it ideal for loose items like snacks, powders, and grains. In contrast, an HFFS (Horizontal Form Fill Seal) machine operates on a horizontal plane, pushing single, solid products like candy bars or medical devices into the packaging. The choice depends entirely on product characteristics.

How fast can a vertical form fill seal machine operate?

Operational speed varies based on machine model, product, and bag size. Intermittent motion machines typically run between 30 and 100 bags per minute (BPM). For higher throughput demands, continuous motion models can achieve speeds exceeding 300 BPM. Maximizing speed and efficiency requires a system correctly configured for your specific application, ensuring consistent, high-performance output that you can depend on for years to come.

What types of bag styles can a VFFS machine produce?

VFFS machines offer significant flexibility in creating various bag styles to meet market demands. Common formats include the standard pillow bag, the gusseted bag for increased volume, and the stable block bottom bag, which stands upright on shelves. More advanced systems can also produce premium styles like the quad seal bag. This versatility allows you to choose the optimal packaging for both product protection and retail presentation, ensuring a high-quality result.

What is the typical cost range for a VFFS machine?

Investing in a VFFS machine is an investment in your production line’s performance and reliability. Entry-level models may start around $20,000, while high-speed, fully integrated systems with advanced weighers, printers, and applicators can exceed $200,000. As your long-term partner, we help you configure a system that provides the durability and efficiency your operation requires, ensuring a strong return on your investment through decades of dependable service.

How much maintenance does a VFFS machine require?

While our machines are engineered for unmatched durability, preventative maintenance is key to ensuring long-term, peak performance. A standard routine includes daily inspections and cleaning, along with weekly lubrication of specified components. This proactive approach minimizes wear and prevents unscheduled downtime. We provide comprehensive support and documentation to make maintenance straightforward, protecting your investment and guaranteeing consistent operational reliability.

Can a VFFS machine handle different bag sizes?

Yes, a single VFFS machine is designed for versatility and can handle multiple bag sizes. Size changeovers are managed by swapping the forming tube and collar assembly, a component that dictates the bag’s width. Modern equipment is engineered for quick, often tool-less, changeovers to maximize uptime and operational efficiency. This adaptability ensures your machine can grow with your product line, providing lasting value and production flexibility.

Recent Comments