Robotic Palletizing Systems

For more than 40 years Choice Bagging Equipment has supplied high quality, cost effective, robotic palletizing systems built to perform. We know that many customers who manually palletize bags realize it is a bottleneck or weakness in their process. By partnering with us they can easily implement an automatic palletizer machine addressing this deficiency and delivering a high return on investment. Not to mention the improved workplace safety they’ll achieve by eliminating a tedious, dangerous physical task. Lastly, an automatic palletizer ensures bags are uniformly stacked on every pallet.

We offer system layouts for virtually any application. However, we can also design a custom configuration for an existing area in a plant. In slower speed operations robotic palletizing systems stack pallets directly on the floor. For increased speed and productivity add automatic empty pallet dispensers, filled pallet transfer conveyors, and automatic stretch wrappers.

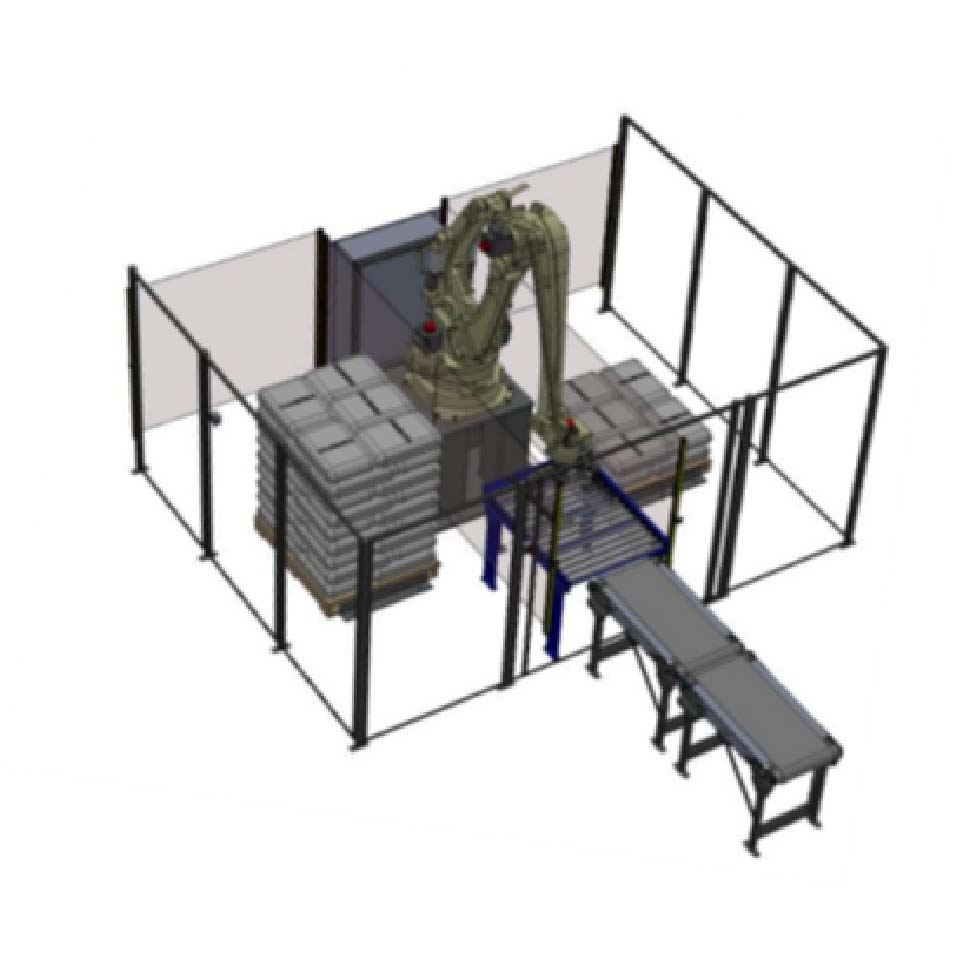

Model 3100 Hot Swap Bag Palletizer

Our Model 3100 robotic bag palletizer is typically used in applications stacking between 1-12 bags per minute. This palletizer machine automatically accumulates and indexes filled bags to a pick station where it stacks the bags onto pallets. In addition, the palletizing work cell has two pallet stacking stations. Bags are placed by the robotic palletizer on one of the stations in a pre-programmed pattern that builds layer by layer until the pallet is completed. After the pallet is finished, the robot pivots to the other side of the work cell. Consequently, an operator can safely enter and remove the filled pallet and reload an empty one so the process can begin again.

Model 3200 Fully Automatic Bag Palletizer

Model 3200 is an automatic palletizer machine frequently used for applications stacking between 12-24 bags per minute. It accumulates and indexes filled bags to a pick station where they are stacked onto pallets. The palletizing work cell also includes a de-stacker to dispense empty pallets and index them onto a conveyorized bag palletizing station. During palletizing, bags are placed on the pallet by the machine layer by layer in a pre-programmed pattern. Once full, the pallet is indexed out of the cell onto an accumulation conveyor or a fully automatic stretch wrapper and the process repeats.

EZ Loader

An EZ Loader pallet carousel is designed to be a true ergonomic tool in every sense of the word. As a result it eliminates the worker bending by automatically raising and lowering pallets during loading or unloading, without the use of mechanical springs. Even more, EZ Loaders allow pallet rotation and as the load weight changes, the EZ Loader pallet carousel automatically adjusts, keeping the top of the load at a convenient working height. Accordingly the patented pneumatic operating system, found only in the EZ Loader, is the top choice of industry professionals worldwide.

Our Palletizer Machines are Versatile & Customizable

Choice Bagging’s robotic palletizer systems are designed to be versatile, with a bag inflow that can be added in any direction. The operator platform and auxiliary air table can also be reconfigured for the specific needs of the client and require very little floor space. Most importantly, it’s helpful to remember that different pieces of machinery can be pieced and milled together using bag handling conveyors to form a custom palletizer system.

Why are Automatic Palletizer Machines Better than Hand Stacking?

First, automatic palletizer machines produce better quality loads reducing product damage during shipping due to irregular hand stacking. Next, they diminish overall worker safety and compliance requirements. This is because automated palletizing eliminates the need for OSHA weight and repetitive motion limits during bag loading. Third, manual stacking slows down production. Conversely, cost effective, small-footprint palletizers actually increase production speed and efficiency. Lastly, don’t overlook other critical factors when considering automated bag palletizing. They include available space, traffic patterns, distance from the packaging to the palletizing area, secondary packaging, and the stability of the finished load to name just a few.

How do Robotic Bag Palletizing Systems Benefit Manufacturing?

Robotic palletizing systems configured for direct-to-store delivery by a manufacturer can load large numbers of cases of various sizes and shapes. They can also help to create a leaner, cleaner, safer manufacturing environment. Furthermore, Choice Bagging customers who invest in robotic palletizing systems often see other important benefits. Among them are reduced labor costs, lower contamination risks, improved safety and accuracy, less transport damage, and easier operational scalability.

Robotic Palletizing Systems Can Help Your Business

If you think a robotic palletizing system can help your production, Contact Us today and let us simplify the process!

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed