Industrial Valve Bag Filling Machine

Brief Overview

Industrial valve bag filling machines optimize packaging for bulk materials across construction, agriculture, and chemical sectors by ensuring precision and speed. These machines accommodate a wide range of materials, from fine powders to granular substances, providing seamless filling and reducing waste. With advanced features like pneumatic and gravity systems, they enhance production efficiency and adaptability. The integration of automatic palletizers further augments operational capacity, reducing manual labor needs. Companies can substantially elevate their productivity and operational efficiency by employing these sophisticated systems for their packaging solutions.

Key Highlights

- Industrial valve bag fillers efficiently handle bulk materials, enhancing precision and reducing waste in packaging operations.

- Customized for industries like construction and chemicals, these machines employ advanced technologies to optimize material handling.

- Impeller and auger fillers support high-speed bagging, improving operational performance and minimizing downtime.

- Automatic palletizers streamline production, reducing manual labor and enhancing packaging efficiency.

- Maximize efficiency with advanced fillers and best practices, ensuring consistent, precise valve bagging operations.

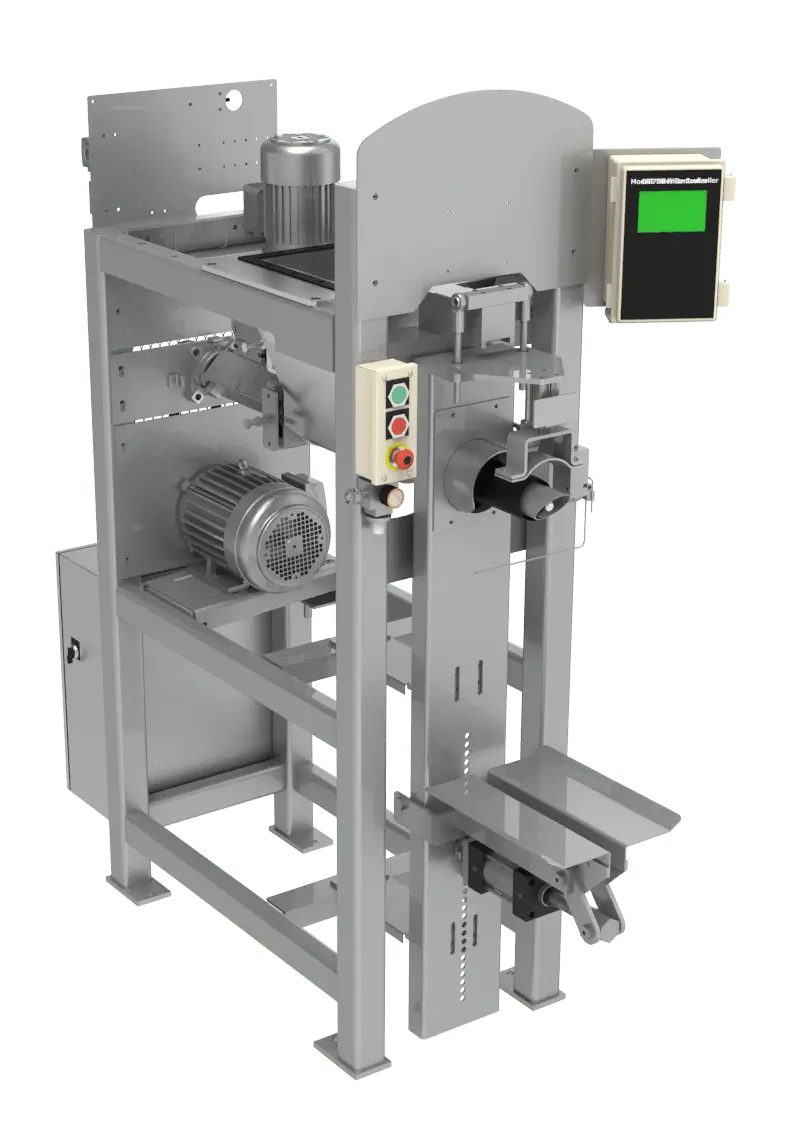

What Is An Industrial Valve Bag Filling Machine?

Industrial valve bag filling machines are essential in industries that handle bulk materials. These machines, designed for both automatic and manual operation, accommodate diverse materials, including industrial minerals, chemical powders, and construction products. The machines integrate seamlessly with conveying systems to enhance operational efficiency. When choosing valve bag fillers, consider the type of material you’re packaging. From gravity-fed to pneumatic options, each provides unique benefits, adapting to various operational needs. Discover how these machines can transform your bagging operations by visiting our Valve Bag Fillers.

What is a Valve Bag Filling Machine?

A valve bag filling machine is a specialized piece of equipment used for packaging powdered and granular bulk materials into valve bags. These machines utilize advanced technology to ensure precision filling, minimizing waste and maximizing efficiency. They operate through various mechanisms such as air pressure or gravity, depending on the product’s characteristics. Industries ranging from construction to chemicals rely on these machines for their robust performance. With features like automatic and semi-automatic controls, valve bag fillers provide customizable solutions for diverse packing needs, enhancing productivity and operational accuracy.

Materials Suitable for Valve Bagging

Valve bagging is ideal for a range of bulk materials, from agricultural products to industrial minerals. The machines are equipped to handle different viscosities and densities, thanks to options like pneumatic conveying and gravity systems. Materials such as fine powders, chemical components, and various construction products are efficiently packaged in valve bags, ensuring secure and contamination-free storage. The versatility of these bag fillers allows companies to meet precise packaging requirements while maintaining the integrity of the materials. This adaptability makes valve bag fillers a crucial component in modern packaging processes.

Types of Valve Bag Fillers

Valve bag fillers are vital in industries ranging from construction to agriculture by streamlining the packaging of bulk materials. Among these, impeller and auger fillers are prominent, excelling in their respective domains. Each type of filler offers distinct advantages by catering to specific material types and operational setups. Understanding these methods allows industries to enhance their bagging efficiency, reduce material waste, and ensure precise packaging solutions. By optimizing machine selection, businesses can achieve greater productivity and meet diverse packaging needs effectively.

Understanding Impeller Fillers

Impeller fillers play a crucial role in high-speed bagging applications, particularly for materials that flow easily. These machines use a rotating impeller to introduce products into valve bags swiftly and consistently. Popular in industries that handle fine powders – such as chemical powders and cement – impeller fillers ensure precision packing with minimal air consumption. The equipment’s efficiency helps enhance overall operational performance by reducing downtime and maximizing throughput. Transitioning to impeller fillers can significantly benefit companies looking to streamline their packaging processes for bulk, free-flowing materials.

The Role of Auger Fillers

Auger fillers are essential for efficiently handling and packaging non-free-flowing materials and various viscosities. Using a helical auger screw, these machines are ideal for industries requiring precision filling of products like granules and formulations that demand careful handling. Auger fillers provide controlled filling rates, which is paramount in achieving consistent packaging outcomes. This minimizes product spillage and enhances packaging efficiency. Industries utilizing auger fillers can optimize their procedures by ensuring that each valve bag is filled with accuracy, thereby improving both productivity and material handling.

Efficiency and Speed in Valve Bag Filling

Enhancing operational throughput and precision, valve bag fillers are pivotal in modern industries dealing with bulk materials like construction products and chemical powders. They integrate seamlessly with existing conveying systems, offering unparalleled filling efficiency. Depending on the machine type, valve bag fillers can manage a wide range of bagging operations thanks to their unique mechanisms. Discover the power of optimized valve bag filling machines and how they can accelerate your packaging processes by exploring our detailed guide on the Model 8300 Digital Vertical Impeller Bag Filler.

Bags Filled Per Minute: What to Expect

The efficiency of valve bag fillers in industrial settings is best measured by their output capacity, often quantified as bags filled per minute. These machines excel in optimizing packaging operations, with some models delivering impressive speeds due to advanced automatic and semi-automatic control systems. Gravity and pneumatic options offer distinct benefits, ensuring the right fit for every industry’s specific material needs. With an efficient setup, businesses can expect to fill dozens of bags per minute, significantly boosting productivity and minimizing downtime. Discover how choosing the right machine can streamline your operations and enhance overall efficiency.

Features and Benefits of Valve Bag Filling Systems

Valve bag filling systems are instrumental in elevating packaging efficiency for industries involved with bulk materials. These systems are engineered to reduce waste and enhance performance, ensuring that products like industrial minerals and chemical powders are packed effectively. Designed for both automatic and manual operations, valve bag fillers provide customizable solutions to fit varied industry requirements. By integrating advanced technology such as pneumatic conveying and gravity systems, these systems not only streamline packaging processes but also optimize material handling. Read on to discover the benefits that these systems offer.

Reducing Waste and Enhancing Performance

Valve bag filling systems are tailored to minimize waste and boost efficiency, crucial for industries such as construction and agriculture that rely heavily on precise packaging. The systems utilize advanced mechanisms like pneumatic conveying and gravity baggers to ensure minimal product loss during filling. By choosing the right filler, be it air packer or gravity-fed options, industries can significantly reduce spillage, leading to cost savings and environmental benefits. Moreover, these systems are equipped with automatic fillers to deliver consistent performance, optimizing the number of valve bags filled per cycle and driving operational success.

Beyond minimizing waste, valve bag filling systems offer multiple advantages that elevate industrial operations.

- Enhanced dust control maintains cleaner work environments and improves workplace safety.

- Automated adjustments reduce manual intervention, ensuring consistent bag weight and product quality.

- Energy-efficient designs decrease operational costs and environmental footprints.

- Advanced integration capabilities streamline connectivity with existing industrial systems.

- High-speed filling mechanisms increase throughput and productivity in packaging lines.

- Versatile designs accommodate various product types, enhancing system flexibility.

- Durable construction ensures longevity and reduces maintenance requirements.

- Improved ergonomics reduce operator fatigue and injury risks.

Embracing these innovations can transform both efficiency and sustainability within demanding industrial environments.

Enhancing Production with Automatic Palletizers

Integrating automatic palletizers into your operation can significantly boost production efficiency. Ideal for industries handling heavy or bulk materials, these palletizers streamline the transportation and stacking stages, working seamlessly with existing systems like conveyors and filling machines. As a critical component of automation, they reduce manual labor and mitigate risks associated with manual handling, thus enhancing overall productivity. With compatibility in various sectors, including agriculture and construction, they ensure the safe and organized packaging of materials while contributing to a smoother production workflow.

Integrating Palletizers in Filling Machines

Utilizing automatic palletizers within filling machines optimizes the bulk handling process. This integration allows for seamless coordination between the air systems and conveyor lines, enhancing the overall efficiency of packaging operations. By automating the stacking process, these palletizers not only reduce manual labor but also improve accuracy and speed in bagging operations. The synergy of such systems ensures that filled bags are swiftly and safely moved to storage or shipping areas, minimizing downtime and increasing the throughput of your operation. Embrace the benefits of this automation to stay competitive in today’s fast-paced industrial environment.

Practical Tips for Maximizing Filling Efficiency

Maximizing efficiency in valve bag filling machines involves strategic planning and implementation of best practices. Companies handling bulk materials like construction products and industrial minerals can enhance productivity by focusing on optimizing the coordination between fillers and conveying systems. Techniques such as choosing the right type of filler based on material properties and integrating advanced equipment like automatic palletizers significantly improve operations. Explore our advanced valve bag fillers to discover more about streamlining your packaging process and achieving superior output.

Best Practices for Valve Bagging

Employing the best practices for valve bagging ensures not only increased efficiency but also consistency in the packaging process. Start by selecting the appropriate bagging equipment; choose between air and gravity systems according to your product’s characteristics. Proper calibration of machines ensures precision in filling, reducing waste and enhancing overall performance. Incorporating automatic fillers can expedite the process by minimizing manual interventions, thus speeding up bag handling. Regular maintenance and training for operating personnel further guarantee that your systems function optimally, meeting the rigorous demands of industrial-scale bagging operations.

Investing in an industrial valve bag filling machine transforms the efficiency and accuracy of your production processes, ensuring precise and reliable bagging solutions for an array of materials like powders and granules. This advanced equipment not only maximizes throughput but also minimizes waste and downtime, providing an exceptional return on investment for industries ranging from construction to agriculture. Choose Choice Bagging Equipment for customized, state-of-the-art solutions that align perfectly with your operational needs, thus propelling your business towards greater productivity and success. Contact us now to explore how we can enhance your packaging operations.

Frequently Asked Questions

What are industrial valve bag filling machines used for?

Industrial valve bag filling machines are used to package bulk materials such as powdered chemicals, granular minerals, and construction products. They are designed for precision, speed, and efficiency to enhance production capabilities in industries like construction, agriculture, and chemicals.

How do valve bag fillers optimize packaging processes?

Valve bag fillers optimize packaging by employing advanced technologies like pneumatic and gravity systems, reducing waste and ensuring high-speed, consistent filling operations. They integrate seamlessly with conveying systems and can include automatic palletizers to reduce manual labor.

What are some of the key features of valve bag fillers?

Key features of valve bag fillers include the ability to handle a wide variety of materials, including fine powders and granular substances. They offer advanced features such as automatic and semi-automatic controls, impeller and auger fillers for high-speed bagging, and customization for specific industry needs.

Why are automatic palletizers important in valve bag filling operations?

Automatic palletizers are important because they streamline production by reducing manual labor and improving stacking speeds and accuracy. By working seamlessly with existing systems like conveyors and filling machines, they enhance overall productivity and operational efficiency.

What should companies consider when choosing a valve bag filling machine?

When choosing a valve bag filling machine, companies should consider the material they’re packaging, as the machines are designed to accommodate various viscosities and densities. Other considerations include whether the operation requires pneumatic, gravity, or a combination system, and the desired level of automation. Consulting with experts at Choice Bagging Equipment can help tailor solutions to specific operational needs.

REQUEST A QUOTE!

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed