In the world of packaging, choosing the right filling equipment is crucial for efficiency and product integrity. At Choice Bagging, we’ve made it our mission to help businesses identify the best packaging solutions to optimize performance and reduce downtime. Two commonly used systems are air packers and auger valve fillers. Understanding the distinctions, advantages, and applications of each can have a significant impact on your material handling and packaging operations. In this guide, we’ll walk you through both technologies to help you make a well-informed decision for your specific production needs.

Introduction to Valve Bag Fillers

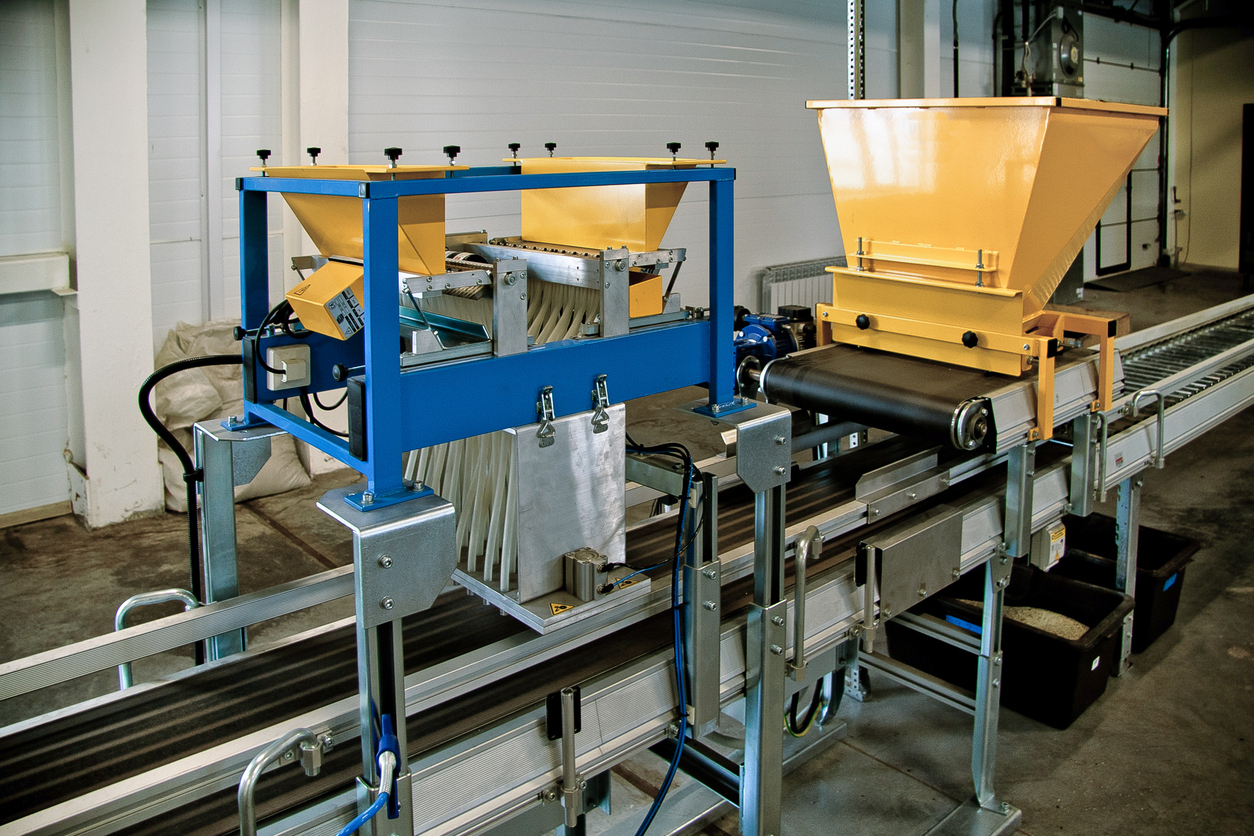

Valve bag fillers are a cornerstone of modern packaging operations, engineered to streamline the process of filling valve bags with a wide range of dry bulk materials. These machines, often referred to as valve bag packers, are designed to handle everything from fine powders to granular products, ensuring that each bag is filled with excellent weight accuracy. The filling process typically involves the operator placing the bag onto a fill spout, where the machine uses air pressure or other specialized filling methods to transfer the product inside the bag efficiently.

Valve bag fillers are highly valued for their ability to accommodate various bag types and materials, making them indispensable in industries such as food, chemicals, minerals, and construction. Whether you’re packaging flour, cement, or specialty chemicals, these machines help maintain product integrity and optimize the packaging process. By automating the filling and sealing of valve bags, businesses can achieve consistent results, reduce manual labor, and minimize product loss due to spillage or inaccurate fills.

Types of Valve Bag Filling Machines

Selecting the right valve bag filling machine is crucial for achieving optimal results in your packaging process. There are several main types of valve bag filling machines, each tailored to specific materials and operational requirements:

- Auger Packers: These machines use a horizontal screw (auger) to convey powders and granular materials into the valve bag. Auger packers are ideal for products that are sticky, cohesive, or require precise dosing, such as bakery mixes, pigments, and specialty chemicals.

- Impeller Packers: Impeller packers utilize a multi-blade impeller to move material into the bag using centrifugal force. This type of valve bag filling machine is best suited for fine, free-flowing powders like cement, flour, and minerals, offering high-speed filling and consistent results.

- Air Packers (Pneumatic Packers): Air packers rely on air pressure to blow material into the bag, making them highly effective for free-flowing powders and granules. They are known for their speed and clean operation, making them a popular choice for high-volume applications.

- Vacuum Packers: Vacuum packers use negative pressure to draw material into the bag, which is particularly useful for lightweight or dusty products that require gentle handling and minimal dust emissions.

Each type of valve bag filling machine is engineered to handle specific materials and bag types, so it’s essential to assess your product characteristics and production goals to select the right valve bag filling solution for your needs.

Understanding Air Packers

Air packers, also known as pneumatic packers, use pressurized air to fill valve bags with fluidized materials, primarily powders, pellets, and some granulated products. This innovative technology relies on a mechanism that incorporates a supply hopper, an air chamber, and a discharge spout, which is one of the filling spouts used in the system to direct the material into the bag until the desired weight is achieved. In manual operations, the operator places the bag onto the filling spout. The fill cycle involves the activation of the air chamber and discharge spout to transfer product through the opening of the valve bag, where the filling process occurs, and automatically stops when the target weight is reached.

How Air Packers Operate

The process begins as product flows down from a hopper into an air pressure chamber. Air pressure then forces the material into the bag, efficiently filling it to the target weight. This method provides a reliable way to manage diverse materials while minimizing handling complexity.

Advantages of Air Packers

- Speed: Air packers offer exceptional filling speeds, often filling up to 12 bags per minute, which can enhance production rates significantly.

- Accuracy: With their design, air packers maintain high filling accuracy while reducing product waste, making them efficient for high-volume operations.

- Simplicity: Operating air packers is straightforward and involves fewer moving parts, resulting in less maintenance and wear.

- Clean Operation: The design minimizes dust spillage, creating a cleaner working environment that’s beneficial for both the operator and the product.

Common Applications for Air Packers

Air packers excel in handling free-flowing materials. You’ll often find them in industries dealing with:

- Concrete and construction products

- Chemicals like fertilizers

- Fine powders such as carbon black and various seeds

- Pellets

Their capability to fill a diverse range of powders and granules makes them a favored choice when speed is essential.

Understanding Auger Valve Fillers

Auger valve fillers stand out by using a rotating screw, or auger, to dispense powders, flakes, and granular materials with precision. This technology is especially effective for measuring and distributing materials that may not flow as freely as others, including those with varying bulk densities measured in pounds per cubic foot.

Auger valve fillers can accommodate different bag types, such as poly, tuck-in, heat seal, and sonic-seal, making them suitable for a wide range of applications and moisture protection needs.

For industries with strict hygiene requirements, auger valve fillers can be designed for food grade applications, ensuring safe handling of food products and compliance with industry standards.

How Auger Valve Fillers Operate

In this system, the material is drawn from a supply hopper and fed into a fill spout driven by the rotating auger. The auger’s movement accurately controls how much material is dispensed, ensuring precision even with challenging product characteristics such as stickiness or cohesion.

Advantages of Auger Valve Fillers

- Accuracy: Auger fillers boast excellent weight accuracy, typically within ±0.5 to 1%, making them ideal for precise packaging.

- Air Management: These fillers excel at minimizing air entrapment, significantly lowering the risk of bag bursting during filling.

- Versatility: Auger valve fillers handle a variety of materials, including sticky and cohesive products. This includes bakery mixes, chemicals, flours, and even pigments.

- Maintenance Ease: The auger is removable, facilitating easy cleaning, which is vital in industries that require stringent hygiene standards.

Common Applications for Auger Valve Fillers

You’ll often find auger fillers in sectors that require not just precision but also reliability with difficult materials. Typical applications include:

- Powdered food products

- Pharmaceuticals

- Specialty chemicals and pigments

- The food industry, where maintaining product integrity and packaging efficiency is critical

These unique capabilities make auger valve fillers essential for applications where control and material properties are crucial.

Choosing the Right Valve Bag and Valve Type

Selecting the appropriate valve bag and valve type is just as important as choosing the right filling machine. The compatibility between your product, the valve bag, and the filling equipment can significantly impact the efficiency and cleanliness of your packaging process.

When choosing a valve bag, consider factors such as the material’s flow characteristics, particle size, and dustiness. Valve bags are available in various materials, including paper, polyethylene, and woven polypropylene, each offering different levels of strength, moisture resistance, and suitability for specific products. The right valve bag will help maintain product integrity and minimize dust emissions during filling.

Valve types also play a crucial role in the packaging process. Common options include self-closing valves, which automatically seal after filling to prevent product leakage, and internal or external sleeve valves, which offer different levels of sealing and ease of stacking. The choice of valve type should align with your product’s properties and your operational requirements, ensuring a secure seal and efficient handling throughout the supply chain.

By carefully matching your valve bag and valve type to your product and filling machine, you can optimize the filling process, reduce waste, and ensure that every filled bag meets your quality and performance standards.

Comparing Air Packers and Auger Valve Fillers

When deciding between air packers and auger valve fillers, it’s essential to assess several critical factors. One of the most important considerations is the available space in your facility, as this will determine how easily the equipment can be integrated into your current layout and whether additional modifications are needed.

If you plan to scale up operations, using multiple machines as part of an integrated system can significantly increase your throughput and overall efficiency.

Both air packers and auger valve fillers can be fully automated, especially when paired with robotic bag placers, which reduces manual intervention and boosts productivity.

Performance and Efficiency

- Air Packers: They typically offer faster filling rates, which is advantageous for operations that prioritize speed over precision. But, they might struggle with sticky or dense products.

- Auger Valve Fillers: Slower in operation compared to air packers, but they provide excellent control and accuracy. This makes them the preferred choice for materials that are difficult to handle.

Maintenance and Durability

- Air Packers: With fewer moving parts, these systems tend to have lower maintenance needs, translating to less downtime in production.

- Auger Valve Fillers: While generally efficient, they may require more maintenance due to wear on the auger, especially if used with abrasive materials.

Cost Considerations

- Air Packers: Generally feature a more competitive price point for high-speed filling applications.

- Auger Valve Fillers: Typically incur higher initial costs due to the precise components that contribute to their accuracy but may save costs related to material waste and operational efficiency.

Understanding these differences can help tailor your material handling systems to suit your specific operational requirements.

Summarizing, choosing between air packers and auger valve fillers largely hinges on your specific production needs and the materials you handle. If you require speed and primarily deal with free-flowing materials, air packers prove advantageous. Conversely, when precision and the ability to handle challenging materials matter most, auger valve fillers become the better option. Evaluate your material characteristics and operational goals to select the most suitable filling solution.

Frequently Asked Questions

What is the main difference between air packers and auger valve fillers?

Air packers use pressurized air for filling, excelling in speed and managing free-flowing materials, while auger valve fillers utilize a rotating screw for precise dispensing, making them better for dense or sticky products.

How do air packers operate in filling bags?

Air packers fill bags by using pressurized air to push materials from a hopper through an air chamber into the bag until the target weight is reached, ensuring efficient and fast filling.

What are common applications for auger valve fillers?

Auger valve fillers are commonly used for powdered food products, pharmaceuticals, and specialty chemicals, especially when precision is crucial for difficult-to-handle materials.

Are air packers suitable for all types of materials?

Air packers are best for free-flowing materials like powders and granules. They may struggle with sticky or dense products, where auger valve fillers would be more effective.

What are the maintenance needs for air packers compared to auger valve fillers?

Air packers require less maintenance due to fewer moving parts, while auger valve fillers may need more upkeep because of potential wear on the auger, especially with abrasive materials.

Which filling system is more cost-effective for high-speed operations?

Air packers are generally more cost-effective for high-speed operations due to their competitive price point and lower initial costs, making them an appealing choice for faster filling needs.

Recent Comments