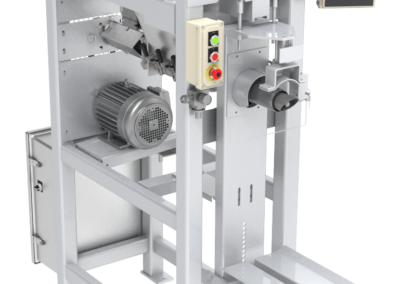

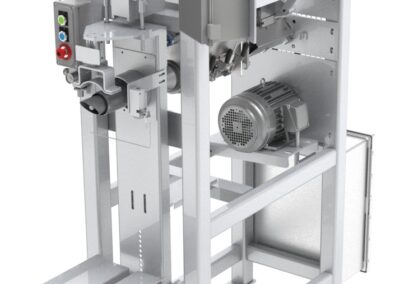

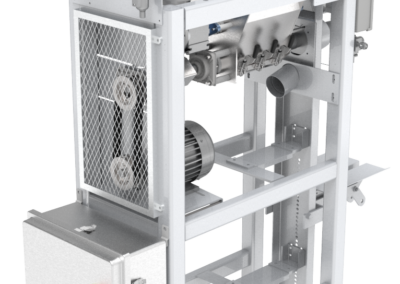

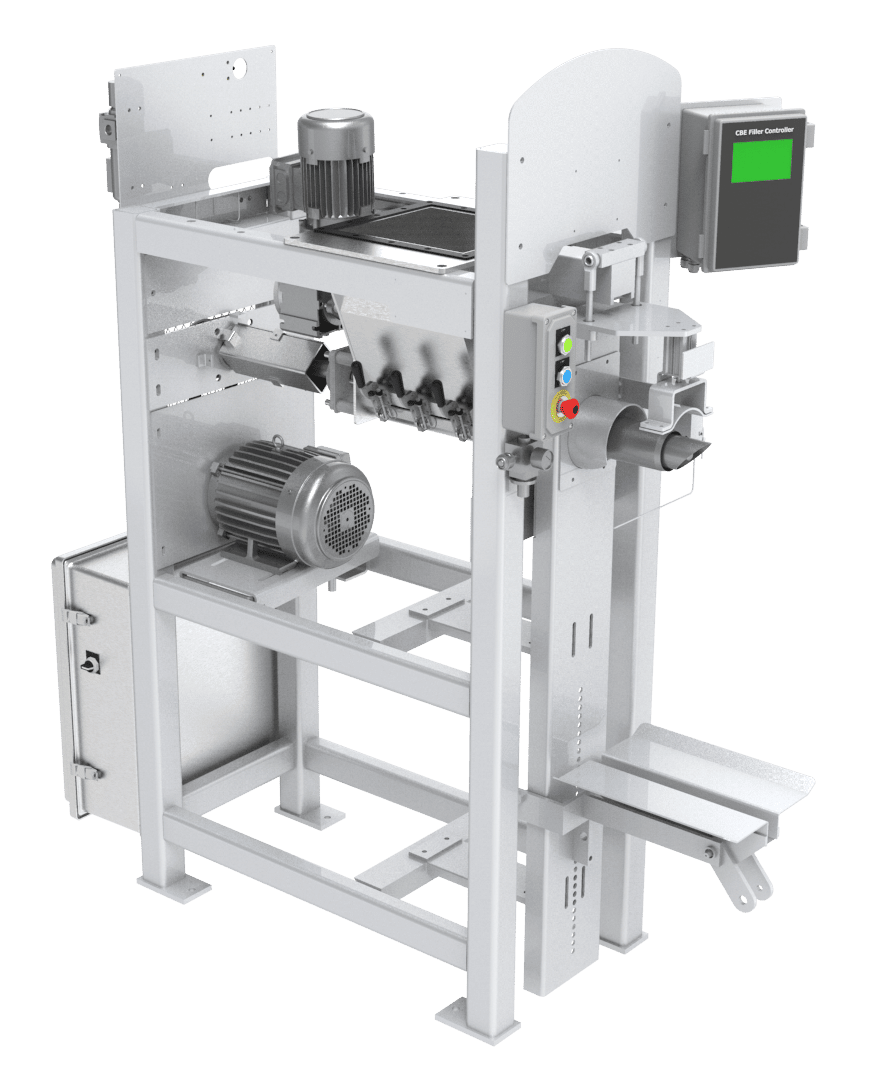

Clean-Duty Auger Valve Bag Filler

Model 2050

The Clean-Duty Auger Valve Bag Filler is designed to bag a wide variety of powders requiring rapid and thorough clean out between production runs. Model 2050 is ideal for sanitary applications or for any need where cleaning after use is necessary to prevent cross-contamination. Interior moving parts such as the auger and agitator blades are quickly and deftly removed for cleanup and inspection.

Click to View Videos

Model 2050 Borax Powder Fill Test

Model 2050 Quick Change Auger Assembly

Examples of Materials Bagged with this Machine

Flour, bakery mixes, cocoa, spices, pepper, animal grade pharmaceuticals, nutraceuticals, pigments, chemicals

Food

Minerals

Chemicals

Specifications:

Bag filling weight range: 20-55 lbs. (9-25 kg)

Production rate: 1-5 bags per minute (material and bag size dependent)

Material density range: 20-75 lbs. (9-34 kg) per cubic foot

Operating modes: Semi- (operator assisted) or fully automatic

Bag types: Internal sleeve and/or tuck-in sleeve paper, plastic film, and poly woven bags

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed