Inaccurate bag weights can silently erode your profit margins, turning valuable product into costly giveaway. When combined with slow, unreliable equipment, these inefficiencies create production bottlenecks that impact your entire operation. For businesses handling free-flowing materials like grains, seeds, or plastic pellets, finding a dependable solution is a financial necessity. The answer is often found in the proven, high-performance design of a gravity bag filler, a technology engineered for both speed and precision.

In this complete guide, we provide the expert insights you need to invest confidently. We will explore how industrial gravity bag fillers deliver unmatched weighing accuracy and operational efficiency for your free-flowing products. You will learn how to select the right configuration for your specific material and gain actionable strategies to optimize your process for maximum throughput and profitability. Prepare to transform your bagging line into a reliable, high-performance asset that achieves consistent, certifiable results.

Key Takeaways

-

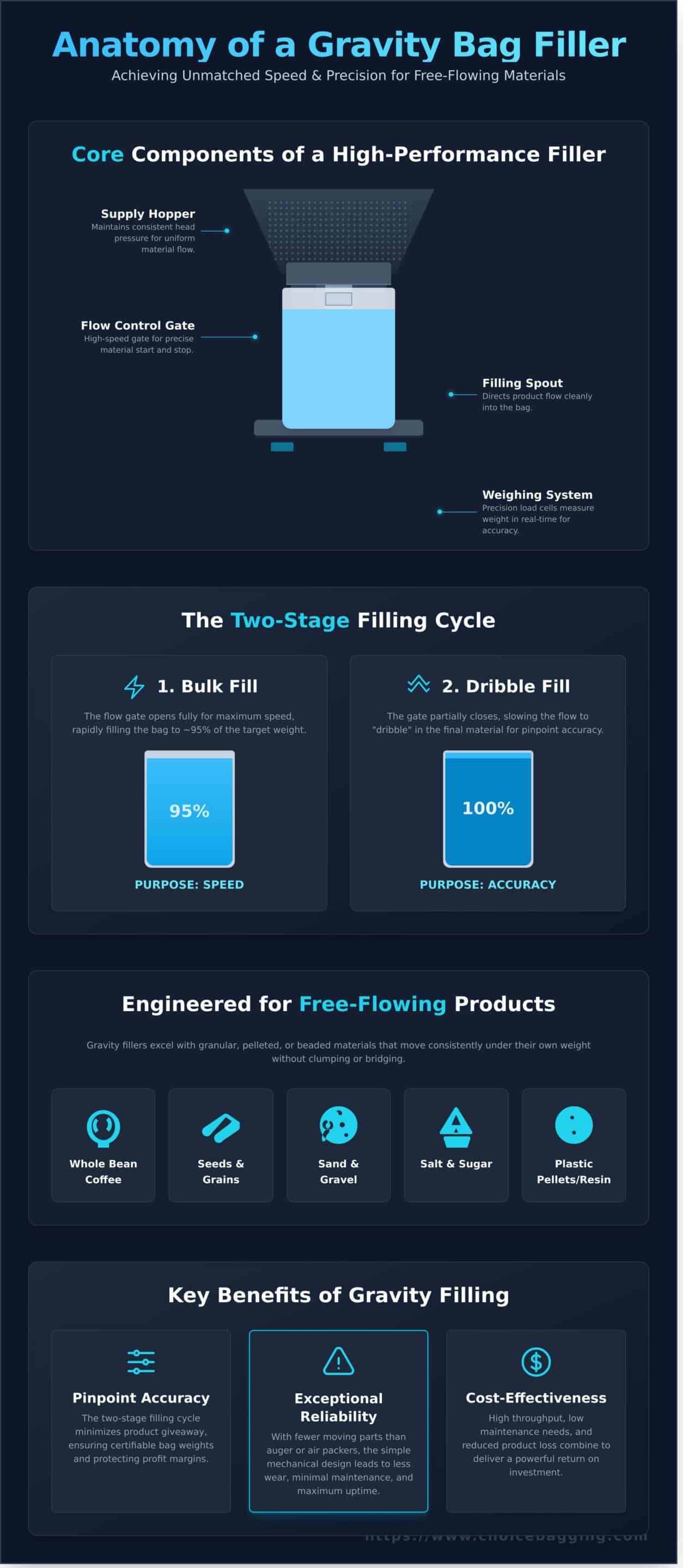

Learn how the core components of an industrial gravity filler work together to ensure reliable and consistent performance for free-flowing materials.

-

Discover the two-stage "bulk and dribble" filling cycle, the proven method for achieving pinpoint weight accuracy and minimizing product giveaway.

-

Implement key optimization and calibration techniques to maximize the efficiency and accuracy of your gravity bag filling operation.

-

Follow essential maintenance practices to ensure your equipment delivers lasting reliability and protects your investment for years to come.

Table of Contents

-

What is an Industrial Gravity Bag Filler (and What It’s Not)

-

Achieving Pinpoint Accuracy: The Bulk and Dribble Filling Cycle

What is an Industrial Gravity Bag Filler (and What It’s Not)

When discussing industrial packaging, the term "gravity bag" refers not to a medical device, but to a highly reliable and efficient type of filling machine. To understand its role, it helps to know what an industrial gravity bag filler is within the broader category of packaging machinery. At its core, this equipment uses the fundamental force of gravity to dose and fill bags with dry, flowable material. Its design is engineered for simplicity and performance, making it a cornerstone for packaging operations that handle specific types of products.

To see this straightforward and effective mechanism in action, watch this video of our Model 600 Gravity Valve Bag Filler:

Unlike auger fillers, which use a screw to move fine powders, or air packers that fluidize materials, a gravity filler offers a direct and mechanically simple solution. This leads to its key benefits: exceptional reliability, minimal maintenance requirements, and outstanding cost-effectiveness. With fewer moving parts, there are fewer opportunities for wear and downtime, ensuring your production line remains operational and efficient.

How Gravity Filling Works: The Basic Mechanism

The process is direct and dependable. Material is stored in a supply hopper or bin directly above the filler. When an operator places a bag on the filling spout, a flow gate-such as a slide gate or a pinch valve-opens. Gravity pulls the product down through the spout and into the bag. An integrated scale constantly monitors the weight, and once the precise target weight is achieved, the gate closes instantly to stop the flow.

Ideal Products for Gravity Bag Fillers

The success of a gravity bag filler is tied to product characteristics. It is engineered for granular, pelleted, or beaded materials that are "free-flowing"-meaning they can move consistently under their own weight without clumping, bridging, or packing together.

-

Whole bean coffee

-

Seeds and grains (corn, soybeans)

-

Sand and small gravel

-

Salt and sugar

-

Plastic pellets or resin

Conversely, these fillers are not suitable for fine, aerated powders like flour or cement, or sticky products like brown sugar, which require mechanical force from an auger to ensure an accurate fill.

Gravity Fillers within a Larger System

Gravity fillers are a specific type of open mouth bag filler , built to work with bags that have a self-sealing opening. In a modern plant, the filler is rarely a standalone machine. It acts as the heart of an integrated packaging line, working in concert with automatic bag placers, take-away conveyors, check weighers, and robotic palletizers to create a seamless, high-performance automated system.

The Core Components of a High-Performance Gravity Filler

The remarkable reliability of a gravity filler stems from its simple, robust design. With minimal moving parts, its performance and longevity are a direct result of the quality of its core components. Understanding this anatomy reveals why a well-engineered machine delivers decades of accurate, low-maintenance service. Each part is designed for durability and plays a critical role in the precise filling of every gravity bag.

The Supply Hopper and Flow Control Gate

The process begins at the supply hopper, a surge bin positioned directly above the filler that maintains a consistent head pressure of material. This consistency is essential for uniform product flow. The flow itself is managed by a high-speed flow control gate that opens and closes with precision. Different gates are specified for different materials:

-

Slide Gate: A simple, effective design ideal for granular and free-flowing products.

-

Butterfly Valve: Offers a tight seal, making it suitable for finer powders.

-

Pinch Gate: Uses pressure to control flow, excellent for pellets, seeds, or aggregates.

The gate’s design and actuation speed are critical for achieving a clean, fast material cut-off, which is the first step toward hitting exact target weights.

The Weighing System: Load Cells and Scale Controller

The heart of any high-performance filler is its weighing system. Precision load cells, mounted beneath the bag support saddle, measure the product’s weight in real-time as it enters the bag. These sensitive instruments send constant data to a digital scale controller-the brains of the operation. The controller manages the fill cycle, typically using a two-stage (bulk and dribble) feed to achieve exceptional accuracy. This system is engineered to meet the stringent requirements for weighing devices, as outlined in official standards like the NIST Handbook 44, ensuring every fill is consistently reliable.

The Filling Spout and Bag Clamping Mechanism

The filling spout is engineered to direct the flow of material cleanly and efficiently into the valve bag, minimizing product aeration and dusting. Surrounding the spout is a secure bag clamp that holds the bag firmly in place during the entire fill cycle, preventing spills and ensuring a proper fill. This mechanism can be manual for lower-speed operations or fully automatic to maximize throughput. For dusty products, our spout and clamp assemblies often integrate dust collection shrouds, maintaining a clean and safe work environment for your operators.

Achieving Pinpoint Accuracy: The Bulk and Dribble Filling Cycle

Achieving consistent, accurate weights is not magic; it is a result of a controlled, repeatable process engineered for precision. Modern valve bag fillers rely on a proven two-stage method known as the Bulk and Dribble cycle. This intelligent system is designed to maximize speed without sacrificing accuracy, effectively eliminating costly product giveaway and ensuring every bag meets your exact specifications.

Stage 1: The Bulk Fill

The cycle begins with the bulk fill, a stage optimized for maximum throughput. The filler’s gate opens completely, allowing a high-volume flow of material into the bag. This first stage rapidly fills the bag to approximately 90-95% of its final target weight. The objective here is pure speed-getting the majority of the product into the bag as quickly and efficiently as possible before the precision stage begins.

Stage 2: The Dribble (or Fine) Fill

Once the bulk fill target is reached, the machine transitions seamlessly into the dribble fill stage. The gate partially closes, restricting the flow of material to a slow, controlled "dribble." This allows the system to carefully top off the bag to the precise target weight. The controller anticipates the amount of "in-flight" material-product that has passed the gate but has not yet landed in the bag-and commands the gate to shut just before the target is met, ensuring a sharp and accurate cutoff every time.

The Role of the Digital Controller in Precision

The entire process is governed by a sophisticated digital controller, the brain of the filling operation. This component is critical for achieving repeatable accuracy and provides essential quality control features. Key functions include:

-

Recipe Storage: The controller can store dozens of product recipes, allowing operators to switch between different products and bag weights with the push of a button, ensuring consistent parameters for each run.

-

Automatic Preact Adjustment: It continuously monitors fill weights and automatically adjusts the in-flight material compensation (preact) to account for changes in material density or flow characteristics, maintaining accuracy over time.

-

Data Logging and Reporting: Modern controllers log critical data from each fill cycle, providing detailed reports for inventory management and quality assurance. This data validates the performance of your gravity bag filling line.

This combination of high-speed bulk filling and precise dribble control, managed by an intelligent controller, is the foundation of reliable and profitable bagging operations.

Optimizing and Calibrating for Peak Performance

A high-performance valve filler, whether auger or gravity-fed, is only as reliable as its setup and operation. Achieving consistent, accurate weights and maximizing throughput depends on a commitment to proper procedures. At Choice Bagging Equipment, we see ourselves as your partner in performance. This guide provides actionable advice for your team to ensure your equipment operates at its peak potential, because a well-maintained machine is an accurate machine.

Proper Calibration Procedures

Regular calibration is the non-negotiable foundation of accurate bagging. An uncalibrated scale leads directly to costly product giveaway or underweight bags that can damage your reputation. We recommend a simple verification check at the start of every shift and any time the product being run is changed. The process is straightforward:

-

Hang a certified test weight, equal to your target bag weight, from the bag spout.

-

Verify that the scale controller display matches the test weight value precisely.

-

If there is a discrepancy, follow the simple calibration steps outlined in your machine’s manual.

Ensuring Consistent Product Flow

The accuracy of any valve filler, especially a gravity bag filler, is directly tied to a consistent supply of material from the hopper. Maintaining a steady "head" of product ensures uniform pressure and flow rate into every bag. Inconsistent levels can cause weight variations from one bag to the next. Furthermore, be mindful of changes in bulk density-due to aeration or compaction-as this can affect fill accuracy. For materials prone to bridging or ratholing, installing flow aids like industrial vibrators or air pads is essential for maintaining a reliable product stream.

Operator Best Practices

A well-trained operator is your first line of defense against inaccurate fills and unnecessary downtime. Enforcing these best practices will significantly improve the performance of your gravity bag or auger system:

-

Place the bag correctly: Ensure the bag’s valve is fully and squarely seated on the fill spout. This prevents leaks and ensures a proper fill.

-

Allow the cycle to complete: Do not remove the bag until the machine signals the fill cycle is finished. Interrupting the cycle will always result in an inaccurate weight.

-

Avoid interference: Never bump, lean on, or otherwise interfere with the bag or spout during the weighing and filling process, as this can disrupt the sensitive load cells and corrupt the weight reading.

By integrating these procedures, you protect your investment and ensure the long-term reliability and precision engineered into every machine we build. For advanced support or on-site training, contact our team of experts .

Maintenance and Troubleshooting for Lasting Reliability

Your investment in a high-performance valve filler is an investment in your operational efficiency. At Choice Bagging Equipment , we build our machines to last for decades, and a commitment to routine maintenance is the key to unlocking that long-term value. Whether you operate an auger filler or a simple, robust gravity bag filler, proactive care ensures consistent performance and protects your bottom line from unnecessary downtime.

We believe in empowering our partners with the knowledge to maintain their equipment with confidence. This straightforward guide provides a foundation for preventative maintenance and a quick reference for common operational issues.

Routine Preventative Maintenance Checklist

A few minutes of inspection can prevent hours of lost production. Integrating these simple checks into your weekly schedule will ensure your filler operates at peak efficiency and accuracy for years to come.

-

Daily Checks: Visually inspect the fill spout and surrounding areas for material buildup that could impede flow. Verify that the system’s air pressure is at the recommended level for consistent gate and clamp operation.

-

Weekly Checks: Manually test the shut-off gate to ensure it moves freely and closes completely. Run a series of test weights to verify the machine’s calibration remains accurate.

To uphold the original performance standards of your equipment, always use genuine OEM replacement parts . This guarantees a perfect fit and maintains the durability we engineer into every machine.

Solving Common Accuracy and Operational Issues

Even the most reliable equipment can encounter issues. Before a minor problem becomes a major one, consult this troubleshooting guide for quick, effective solutions to keep your gravity bag or auger system running smoothly.

-

Problem: Inconsistent weights.

Solution: The most common cause is a change in product density or flow. Re-calibrate the scale with a known weight. Also, check the product hopper to ensure there are no blockages affecting the flow of material to the filler. -

Problem: Slow filling cycles.

Solution: Inspect the main product gate for any obstructions or material buildup that prevents it from opening fully. Review the filler’s settings to ensure they are optimized for your current product. -

Problem: Dust leakage during filling.

Solution: Examine the inflatable bag clamp seal for wear, cracks, or punctures. Ensure the fill spout is in good condition and correctly sized for your valve bags to create a secure connection.

While these tips resolve most common challenges, some situations require an expert eye. For complex diagnostics or on-site support, our professional field service technicians are ready to assist. As your partner in production, we are committed to ensuring your equipment delivers unmatched reliability. Contact us today to learn more about our support services.

Achieve Unmatched Accuracy with the Right Filling Partner

As we’ve explored, the precision of an industrial filler is determined by its core components and the meticulous bulk-and-dribble filling cycle. Proper calibration and consistent maintenance are not just best practices; they are essential for achieving the repeatable accuracy that protects your bottom line and ensures peak performance for years to come.

Choosing the right equipment is the first step, but selecting the right partner guarantees long-term success. Since 1978, Choice Bagging Equipment has been a trusted manufacturer of durable, high-performance systems. Our team of expert engineers is ready to help you specify the ideal gravity bag filler for your unique application, backed by the quality of reliable equipment proudly Made In The USA.

Don’t leave your operational efficiency to chance. ****Consult an expert about your filling application today and discover the difference that proven engineering and dedicated support can make for your business.

Frequently Asked Questions

What is the typical weight accuracy of an industrial gravity bag filler?

A high-quality industrial gravity bag filler delivers exceptional weight accuracy, typically within +/- 0.5% of the target weight. This level of precision is achieved through consistent product head pressure and reliable gate control. For materials with uniform density and good flow characteristics, like plastic pellets or grains, our systems ensure that every bag meets specification, minimizing product giveaway and maximizing your operational efficiency. This reliability is a cornerstone of our equipment design, built to perform for decades.

What is the difference between a gravity filler and an auger filler?

The primary difference lies in the filling mechanism and the materials they handle. A gravity filler relies on the natural flow of the product, making it ideal for free-flowing, granular materials like seeds, grains, or plastic pellets. In contrast, an auger filler uses a rotating screw to dose and dispense non-free-flowing powders like flour or cocoa. Choosing the correct filler is critical for performance, and our team provides expert consultation to ensure you invest confidently in the right solution.

Can a gravity bag filler handle fine powders like flour or cement?

A gravity bag filler is not the appropriate technology for fine, aeratable powders like flour or cement. These materials do not flow consistently under gravity; they tend to bridge, cake, or fluidize, which leads to inaccurate weights and poor filling performance. For such applications, an auger filler or an air packer provides the necessary mechanical assistance to reliably move and densify the product into the bag, ensuring both speed and accuracy for your operation.

How many bags per minute can a gravity filler typically produce?

Production rates for a gravity filler depend on several factors, including product density, target weight, and operator efficiency. A typical single-spout manual gravity valve bagger can reliably fill between 3 to 8 bags per minute. Our machines are engineered for high performance and ease of use, with intuitive controls that help operators achieve and maintain consistent throughput. For higher production needs, we can engineer automated solutions to meet your specific operational goals and ensure maximum efficiency.

How often does a gravity bag filler need to be calibrated?

One of the key advantages of a gravity bag filler is its exceptional reliability and minimal maintenance requirements. Due to their simple design with few moving parts, our fillers hold calibration extremely well. After the initial setup for a specific product, only periodic weight checks are typically needed to ensure continued accuracy. We recommend a quick verification at the start of a shift or when changing products, but frequent recalibration is generally unnecessary for consistent materials.

Is it possible to fill both open mouth bags and valve bags with a gravity filler?

Gravity fillers are specifically engineered for one type of bag. A gravity valve bag filler is designed exclusively for bags with a built-in valve, using a filling spout that inserts into the opening. For open mouth bags, a different system, such as a net weigh scale with a bag clamp and closing conveyor, is required. As your partner in packaging, our experts can help you assess your needs and identify the precise, high-performance equipment solution for your specific bag type.

Recent Comments