Key Features & Benefits

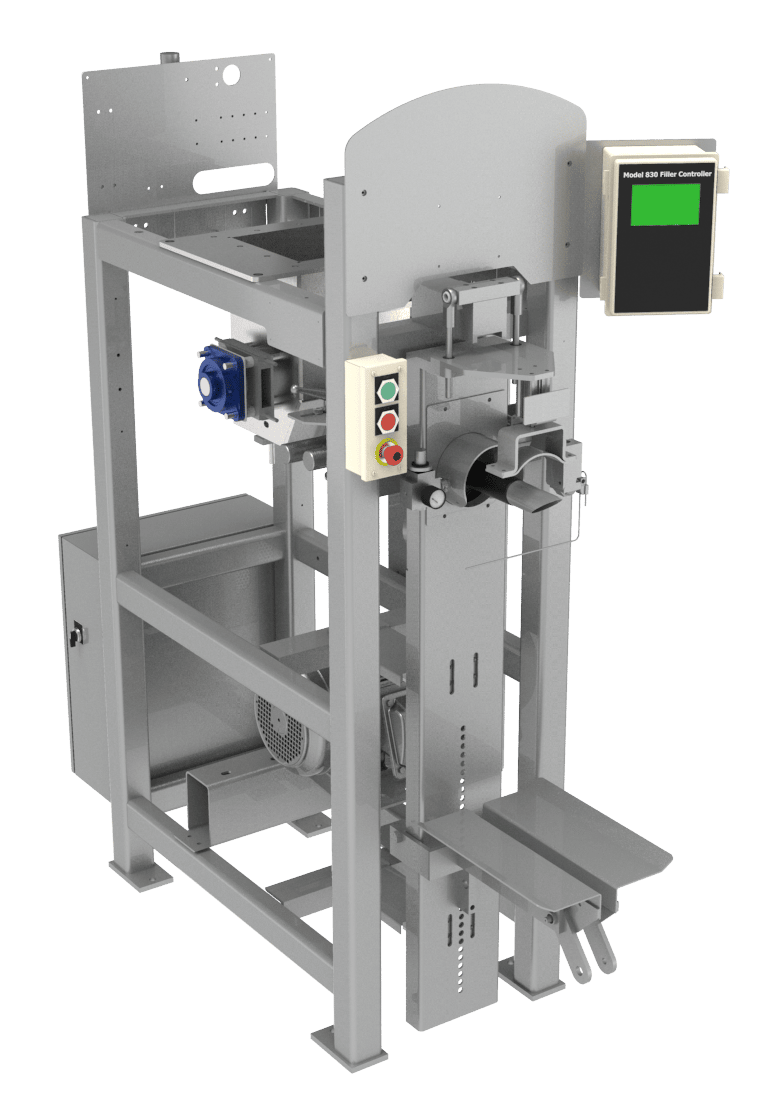

Digital Vertical Impeller Valve Bag Filler – Model 8300

Ideal for fine, aerated, moderate density powders

Designed for continuous, dependable bagging

Easy-to-use touch screen controls

Integrated digital weighing scale with no moving parts

Removable bottom door for rapid cleanout, maintenance, and impeller blade replacement

Handles a wide variety of materials and bag types

Up to 4 machines can be combined together for increased production rates

Standard Equipment:

Digital load cell weighing scale with touch screen controls

Four-blade impeller with twin feeding screws

Bulk only pinch valve cutoff

Single wall, fill spout (sized per customer requirement)

Air-operated clamp holds bags securely for no mess filling

Stop, start, and E-stop push buttons

NEMA 4 electrical enclosures

Industrial Gray Powder Coated Carbon Steel Material contact surfaces

Optional Equipment:

Model 2700 Automatic bag placer

Tool-free adjustable bulk and dribble with 2-speed cutoff

Variable speed motor drive

Single wall, fill spout with inflatable dust seal (sized per customer requirement)

Tapered dust seal cone

Automatic bag discharger

Automatic fill start

304 Stainless steel material contact areas

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed