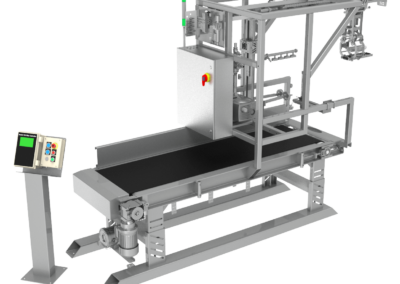

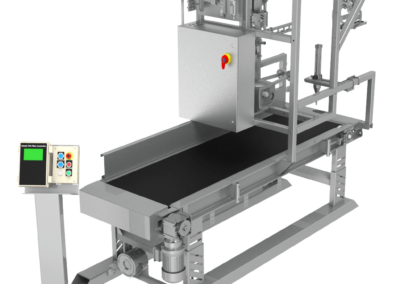

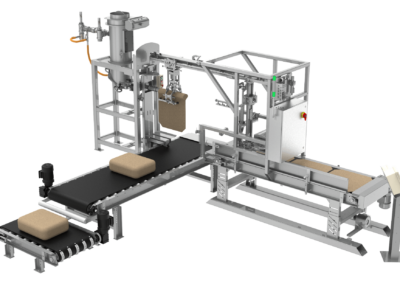

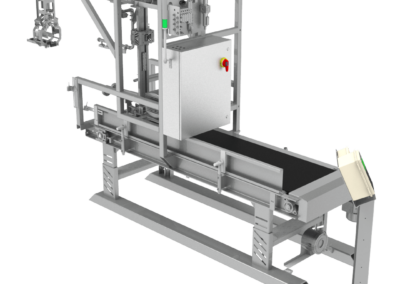

Automatic Valve Bag Placer

Model 2700

CBE’s Valve Bag Placer puts bags on the fill spout and can be used with any of our valve bag fillers. It performs empty bag pick up, opening, and placement to completely automate the operation of a valve bag filling machine.

Click to View Videos

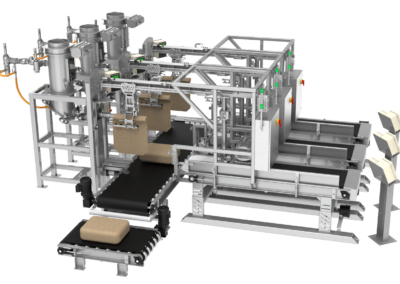

Model 2700 with Valve Bag Filler (1)

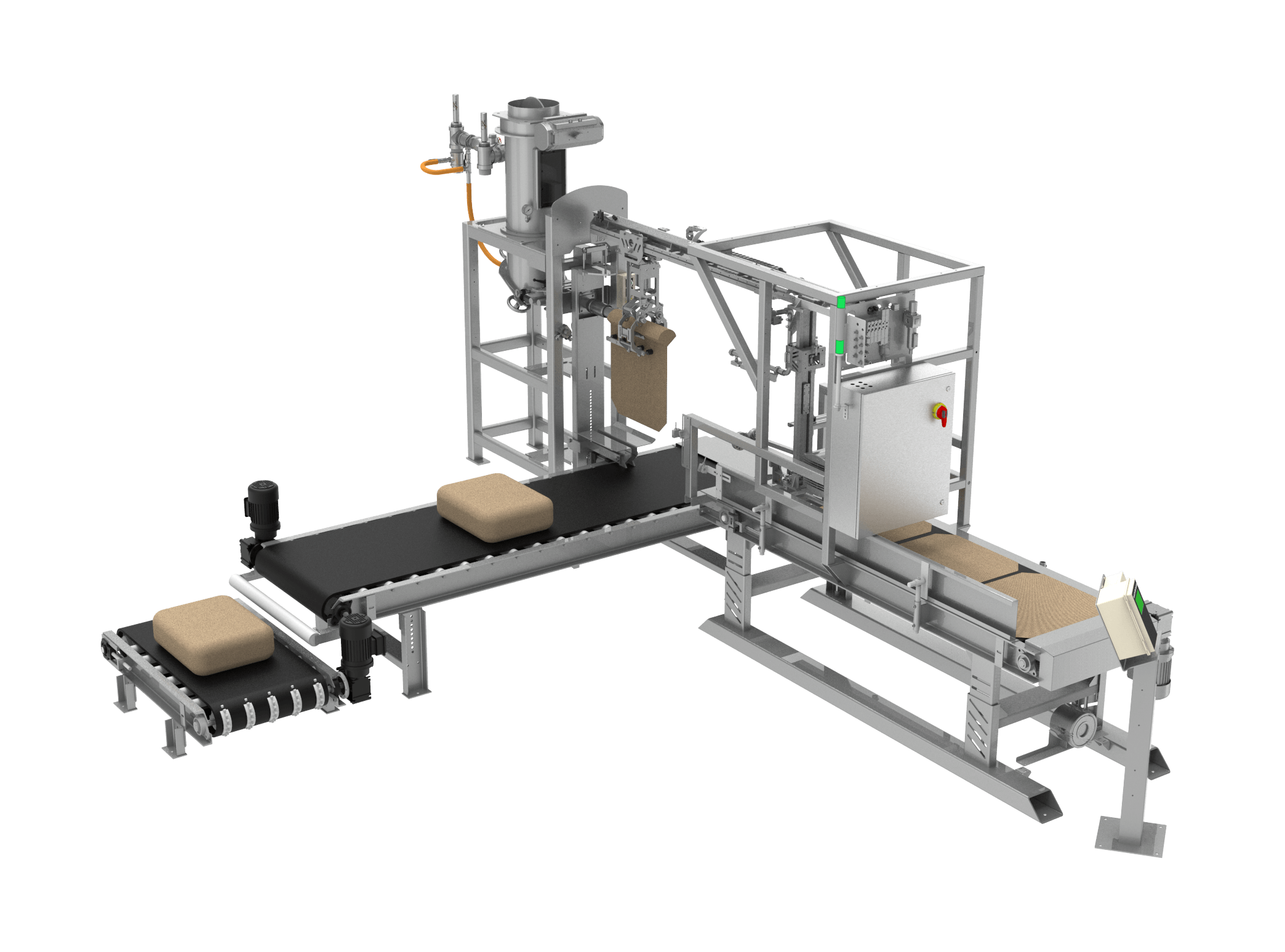

Model 2700 with Valve Bag Fillers (2)

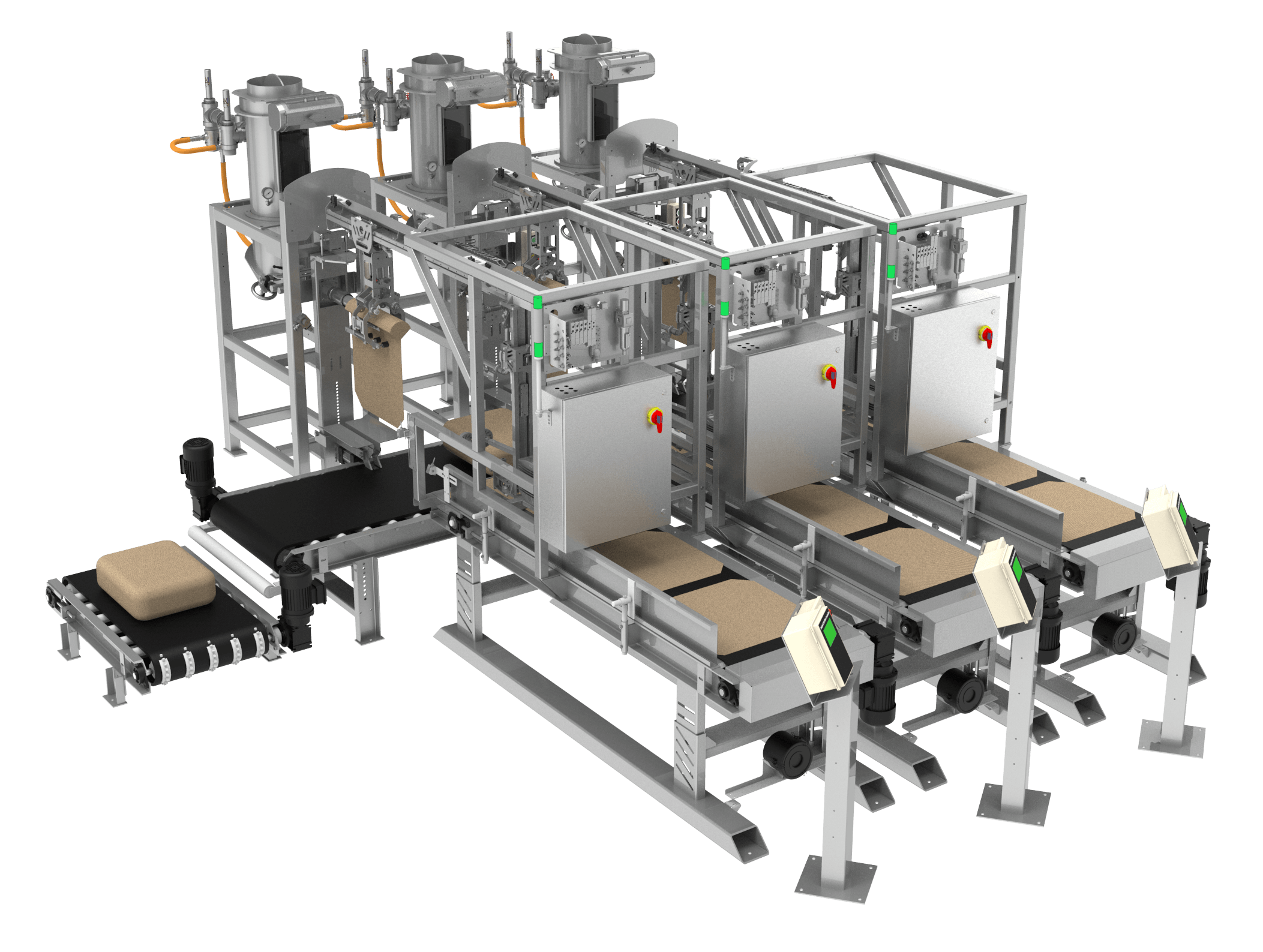

Model 2700 Robotic Bag Placing System with Valve Bag Fillers

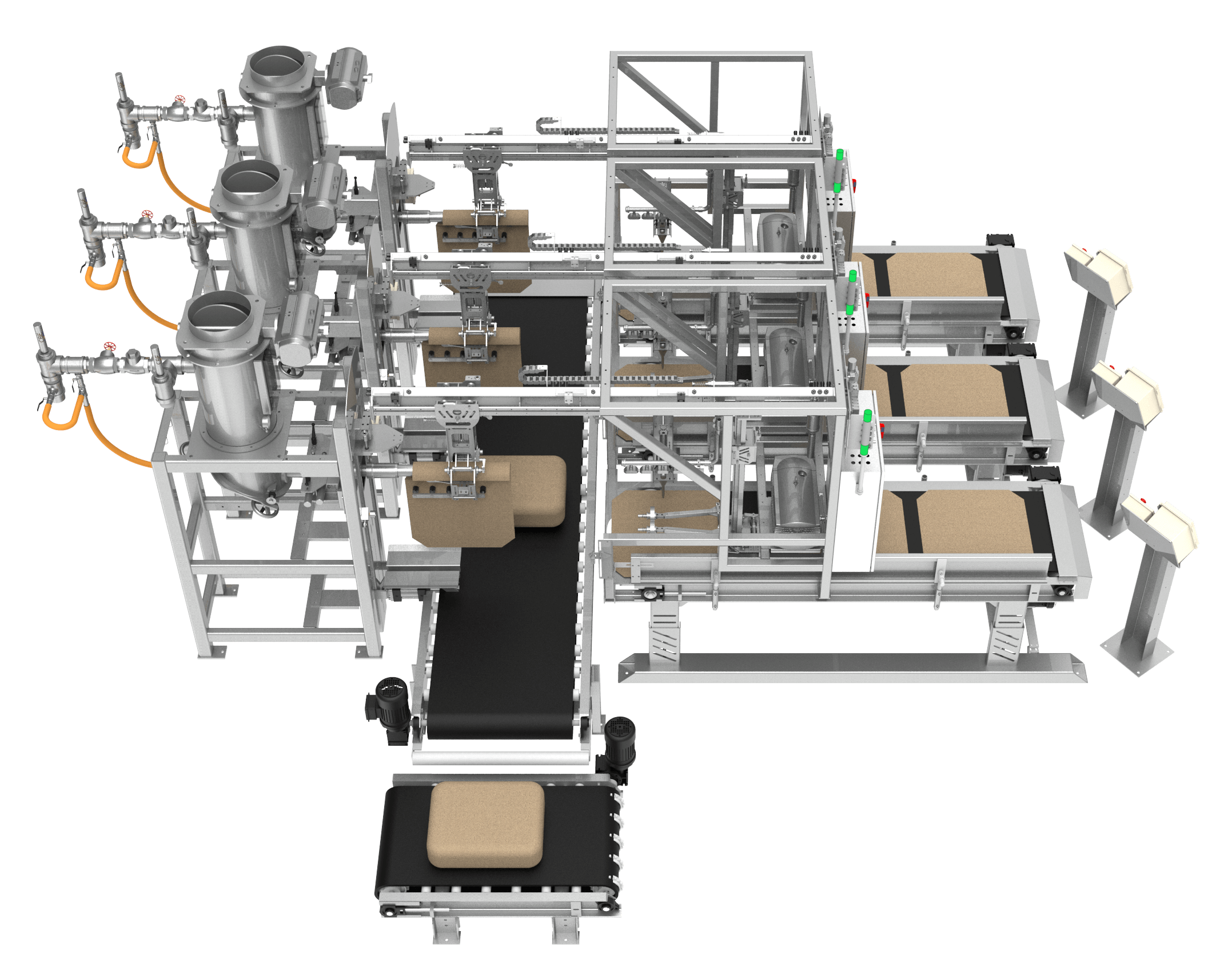

Model 2700 with Valve Bag Filler & Bag Picker, Placer, & Discharger

Key Features and Benefits:

Model 2700 is easy to learn, use, and maintain. Operators can be trained to utilize it in minutes.

When grouped, each placer / bagger unit operates independently. If one stops the others continue uninterrupted. Each unit can begin a run individually or with other machines.

Each bagger has a placing arm. Our traditional placer had a single arm placing bags to multiple spouts. Model 2700 places to just one spout maximizing fill rate with no waiting.

Model 2700 Valve Bag Placer has a magazine capable of holding up to 150 bags (a 2-spout placer will hold up to 300 bags).

Model 2700s control circuit places all bags to all spouts at the same time. It also fills all bags and discharges them the same way. Bags reach the conveyor with even, consistent spacing and don’t fall on each other.

Model 2700s simple technology (air cylinders, solenoids, position switches) means there is nothing a plant mechanic with average skills cannot understand, service or maintain.

The control interface for Model 2700 was designed to allow a new operator to be fully competent to run it on his first day.

Valve baggers with Model 2700s ship fully assembled, are modular, and install easily. Simply align the two pieces and connect a cable between them. If utilities and the bin are ready, installation day bagging is very possible.

Bag and product samples are required to determine the final bagging rate and bag capacity. Please note that each placer can only hold between 130 and 150 bags depending on bag dimensions.

Our Automatic Valve Bag Placer works with all CBE Valve Baggers

Front view with three placer/bagger units

Side view with three placer/bagger units

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed