Automatic Valve Bag Filling Machine

Brief Overview

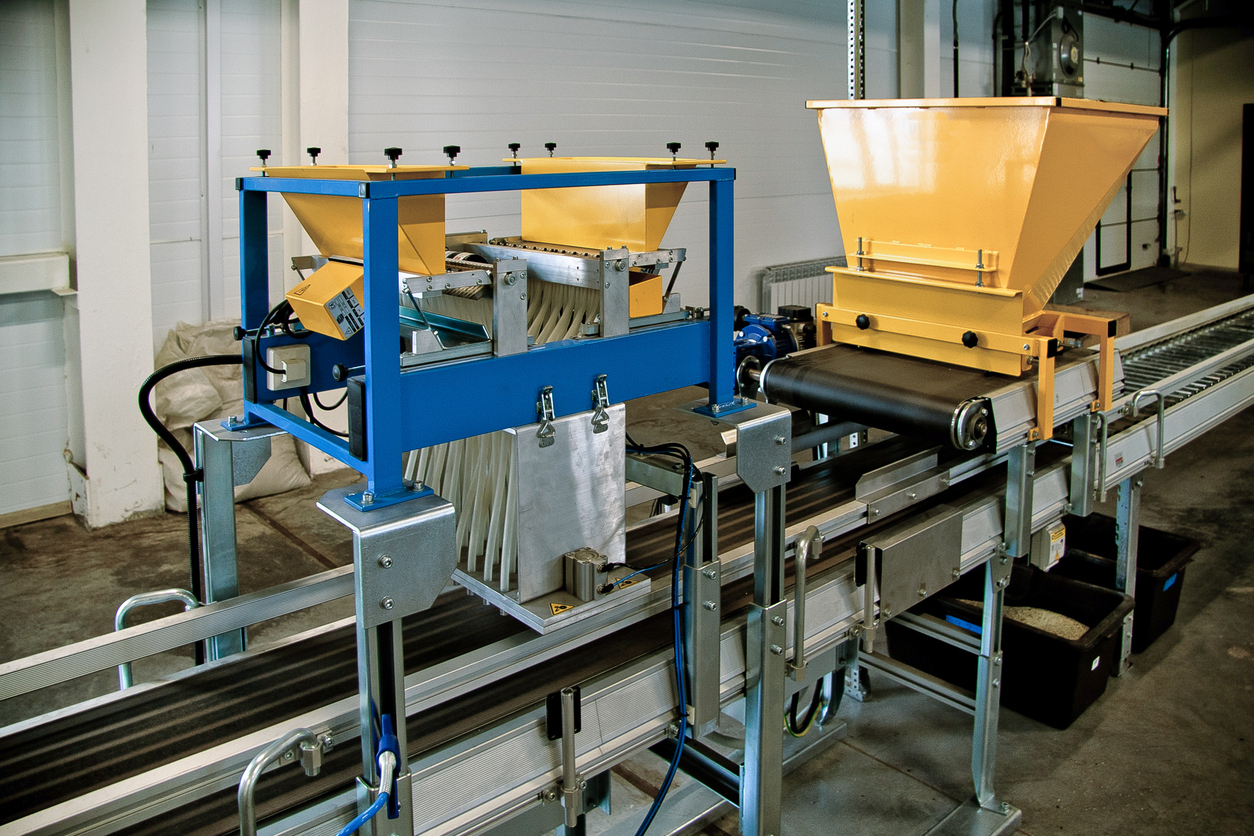

Automatic valve bag filling machines from Choice Bagging Equipment combine efficiency and precision, catering to diverse industries like construction, agriculture, and chemicals. These state-of-the-art systems maximize productivity by seamlessly integrating into production lines, offering advanced features that reduce labor costs and improve operation speed. Businesses can benefit from their adaptability, handling various materials with high-speed precision. Select the right valve bags to enhance machinery performance and ensure consistent results. Discover how these innovative solutions streamline packaging operations, and explore customization options to optimize your unique material handling processes.

Key Highlights

- Automatic valve bag filling machines enhance efficiency and accuracy, ideal for diverse industrial applications.

- Advanced technology in bag fillers minimizes wastage and ensures consistent bag weights.

- Featuring seamless integration, these machines reduce labor costs and boost operational productivity.

- Customizable for different materials, ensuring versatility in construction, agriculture, and chemical industries.

- Explore our range of bagging solutions to transform your packaging operations with Choice Bagging Equipment.

Introduction to Automatic Valve Bag Filling Machines

Automatic valve bag filling machines are revolutionizing how industries handle bulk materials. These machines are designed to enhance efficiency and accuracy in the bagging process, ensuring that bulk materials are packed swiftly and precisely. Utilizing advanced technology, our machines offer seamless integration into existing production lines, making them ideal for businesses focused on maximizing output while minimizing labor costs. From construction to agriculture, these versatile machines are filling a wide array of industrial needs. Learn more about how they work and why they’re essential for any business handling large quantities of product, by visiting our valve bag fillers information page.

Understanding the Mechanism of Valve Bag Filling Machines

At the heart of every industrial operation is a robust machine that brilliantly marries technology with functionality. Valve bag filling machines stand as a testament to this, crafted to efficiently fill valve bags with precision and speed. These units feature a unique valve mechanism designed to direct bulk materials securely into packaging without spillage. By using an automatic valve, these machines ensure that each bag is filled to its optimal level. This process minimizes wastage, boosts productivity, and ensures consistent bag weights, which are crucial for both packaging integrity and customer satisfaction. The precision offered by these bagging machines is unparalleled, owing to their advanced engineering and design.

What sets these bag fillers apart is their versatility, handling a range of bulk materials, from construction products like cement to delicate agricultural produce such as seeds. The equipment can be tailored to fit varied industrial needs, offering customizable fill rates and bag sizes. Furthermore, the automation integrated within each unit reduces manual error and increases operational efficiency. Operators can control the entire filling process via a central console, ensuring seamless coordination between machines and human resources.

Additionally, incorporating these bagging machines into an existing line is straightforward. They are designed for easy maintenance and swift replacement of moving parts. Businesses can quickly adapt to market demands and supply fluctuations without significant downtime. In essence, valve bag filling machines not only streamline packaging operations but also provide a competitive edge by enhancing overall productivity. Discover more about these innovative solutions by exploring our extensive range of products, perfectly aligned with the needs of your business strategy.

Key Features of Industrial Valve Bag Filling Systems

Industrial valve bag filling systems are essential in optimizing the packaging of bulk materials by blending innovation with functionality. These systems harness the potential of advanced technology to ensure precision, efficiency, and adaptability. From handling construction materials to agricultural produce, this equipment meets diverse industrial demands. The systems are equipped with state-of-the-art features that enhance the filling process, reduce manual effort, and increase operational speed and reliability. Understanding their capabilities enables industries to improve productivity while maintaining a high standard of packaging integrity, ensuring every product meets customer expectations. Explore the advantages that make these machines indispensable.

Advantages of Using an Automatic Valve Bag Filler

The implementation of automatic valve bag fillers in industrial operations presents a multitude of advantages. First and foremost, these bag fillers enhance the efficiency of the bag filling process. By utilizing advanced automation, the need for continuous manual intervention is minimized, allowing operators to focus on other value-adding tasks. This reduces labor costs significantly and enhances productivity. The precision of the automatic valve ensures that each valve bag is filled to the optimal level, addressing common issues such as underfilling or overfilling, both of which can lead to wasted materials and inconsistent product quality.

Automatic valve bag fillers also boast superior speed, seamlessly integrating into existing production lines. This capability is crucial for businesses aiming to scale up operations and increase output without compromising accuracy. These machines are designed to handle a variety of bulk materials, such as industrial minerals and chemical powders, making them versatile additions to any production facility.

From a maintenance perspective, automatic valve bag fillers are engineered for longevity with features that make upkeep straightforward. This reduces downtime and ensures that the equipment remains reliable over extended periods. Moreover, businesses can customize the bagging machines to meet specific needs, such as adjusting fill rates or switching between different bag sizes, which enhances the adaptability of the equipment to market variations.

To explore how these advantages can transform your business operations, you may consider reviewing detailed specifications and model options on our website. By doing so, you can ensure that your packaging equipment not only meets but exceeds industry standards, providing a competitive edge in your marketplace.

Types of Valve Bags and Their Applications

Choosing the right valve bag is crucial in optimizing the efficiency of your automatic valve bag filling machine. Different types of valve bags cater to diverse industrial applications, from construction materials to agricultural products, each offering unique features and benefits. By understanding the specific needs of your product, you’ll ensure optimal filling performance and minimize waste. Explore how these valve bags enhance the performance of bag fillers, improving the overall packaging process and ensuring that every application is met with precision and reliability.

Choosing the Right Valve Bag for Your Product

Selecting the right valve bag is pivotal to the success of your filling operations. Valve bags are designed to accommodate various products, ranging from heavy construction materials to light agricultural produce and fine chemical powders. Each type of product demands a specific bag design to ensure efficient handling and optimal use of packaging equipment. When choosing valve bags, it’s important to consider factors such as bag material, size, and closure type to maximize the benefits of your automatic valve bag filling machine.

For construction products, heavy-duty valve bags are ideal. These bags are robust enough to withstand the rigors of transport and storage while ensuring the safe containment of dense materials like cement or sand. The strength and durability of the bag material prevent tears and leaks, safeguarding the integrity of your product throughout its lifecycle. In contrast, for agricultural products, lighter and breathable valve bags might be more suitable. These bags allow air to circulate, preserving the quality of products like grains or seeds by preventing moisture buildup.

Chemical powders and industrial minerals demand precision during the filling process, making the choice of valve bags even more critical. Here, specialty valve bags with fine-tuned closure mechanisms ensure that the product is secured with minimal dust emission and product loss. The right choice of valve bags significantly impacts the efficiency of valve bag fillers, ensuring that each bag is filled precisely to its optimal capacity, thus reducing material wastage and increasing productivity.

Ultimately, aligning your choice of valve bags with product-specific needs will enhance the performance of your bagging machines, sustaining the quality and efficiency of your operations. Feel empowered to explore various valve bag options, and find the perfect fit for your business requirements, setting the stage for smoother, more efficient packaging operations. With an ideal valve bag, your filling machines can truly transform your production line, ensuring that both productivity and quality are never compromised.

When selecting valve bags for various applications, it’s essential to account for several crucial factors to ensure they meet the specific requirements of the products they will contain. Here are key considerations to keep in mind:

- Material Compatibility: Ensure the bag material is compatible with the product to prevent contamination or chemical reactions.

- Bag Strength: Assess the durability and tensile strength to support the weight and handling processes.

- Seal Integrity: Determine the effectiveness of the valve closure in maintaining product integrity during transportation and storage.

- Moisture Resistance: Consider the level of moisture protection required for the product.

- Environmental Considerations: Evaluate the environmental impact and sustainability of the bag material.

- Filling Efficiency: Review the bag’s compatibility with existing filling equipment to maximize operational efficiency.

- Aesthetic and Branding Needs: Account for any printing or labeling requirements to align with brand presentation.

By carefully considering these factors, businesses can select the most appropriate valve bags that not only protect their products but also optimize operational effectiveness and sustainability.

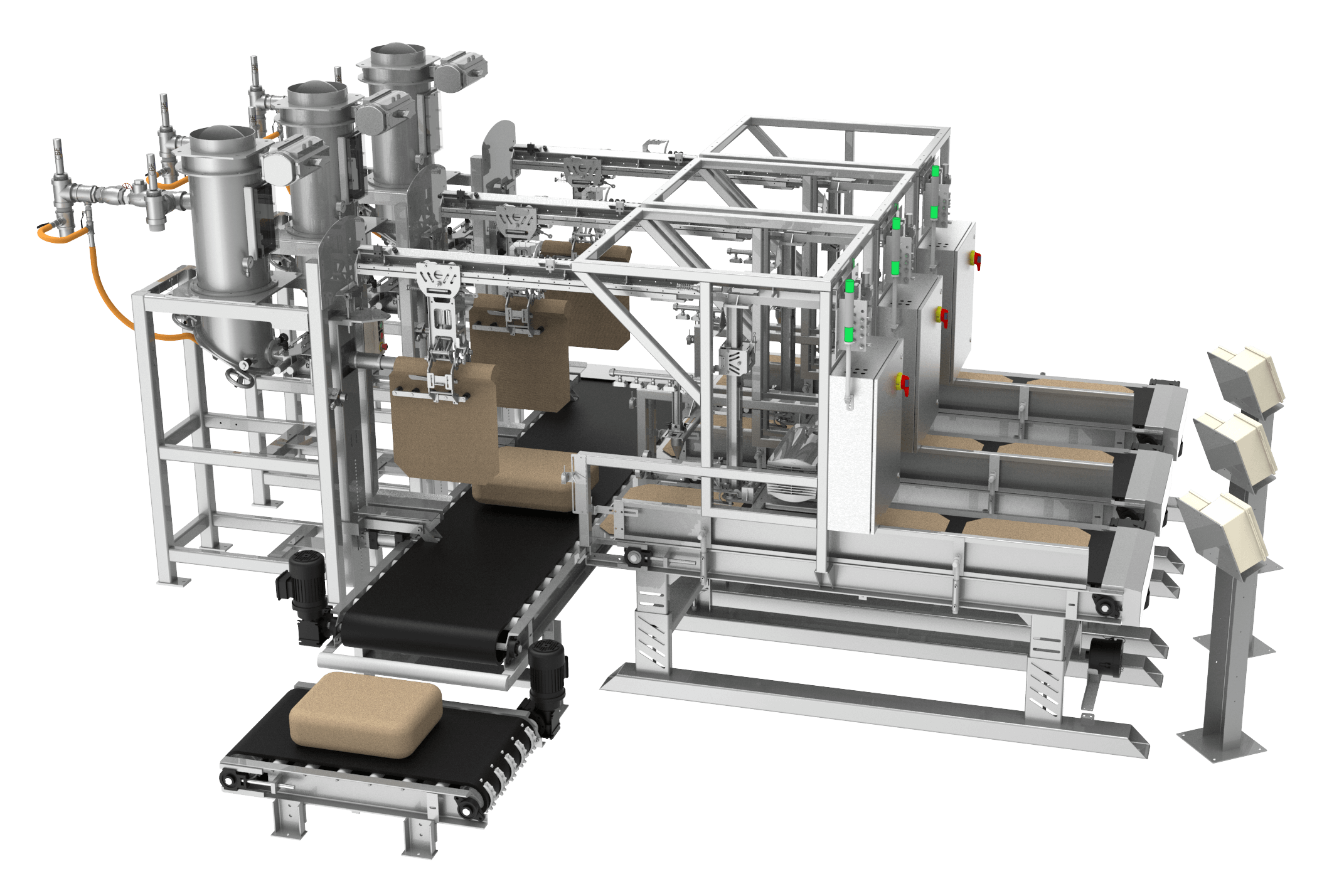

Integrating Bag Fillers into Your Production Line

Integrating valve bag fillers into your production line is a strategic move that can elevate the efficiency and effectiveness of your packaging operations. With the advanced capabilities of automatic valve filling machines, businesses can seamlessly incorporate these industrial giants into their existing setups. The key to successful integration lies in the adaptability of these bagging machines to handle a wide range of bulk materials, from industrial minerals to chemical powders, effortlessly.

One of the primary benefits of adding these machines to your line is the substantial reduction in manual labor. By automating the fill and seal process, bag fillers minimize human error, allowing your workforce to redirect their efforts to other critical tasks within your organization. This boosts overall productivity and ensures that your team is leveraging their skills most efficiently, promoting a harmonious workflow.

Furthermore, these packaging machines are designed with flexibility and scalability in mind, accommodating various bag sizes and materials. This adaptability means your firm can switch between packaging different products with ease, making them indispensable for companies dealing with constructive products, agriculture materials, and more. Businesses also gain an edge through enhanced operational speed, thanks to the machines’ ability to consistently handle large volumes without sacrificing precision.

Choosing a reliable equipment partner is crucial for seamless integration. Companies should consider trusted brands like Choice Bagging Equipment, known for providing robust and well-engineered solutions. For more insight into how these machines can be tailored to suit your specific needs, visit the Model 2300 Valve Bag Filler page. Here, the intersection of durability and advanced technology ensures your production line operates at its peak, fulfilling your packaging needs flawlessly.

Embrace efficiency and precision with our automatic valve bag filling machines, designed to boost productivity across construction, agriculture, and chemical industries. Packed with advanced features and unparalleled adaptability, these systems ensure consistent, high-speed filling operations. Explore our range to find the perfect fit for your unique material handling needs. Contact us today to learn how our innovative solutions can transform your production line, reduce labor costs, and enhance throughput. Partner with Choice Bagging Equipment and take the first step toward seamless, automated bagging processes that keep you ahead in a competitive market.

Frequently Asked Questions

What industries benefit from Choice Bagging Equipment’s automatic valve bag filling machines?

Our automatic valve bag filling machines cater to a range of industries, including construction, agriculture, and chemicals. These industries benefit from the machines’ ability to handle various materials with high-speed precision while reducing labor costs and maximizing productivity.

How do automatic valve bag filling machines enhance productivity and reduce labor costs?

The machines integrate seamlessly into production lines, automating the fill and seal process. This reduces the need for continuous manual intervention, allows operators to focus on other tasks, and minimizes human error, all of which enhance productivity and reduce labor costs.

What are the customization options available for valve bag filling machines?

Our machines can be customized for different materials, fill rates, and bag sizes. This flexibility ensures that the equipment can be adapted to various industrial needs, allowing for the efficient packaging of a wide range of bulk materials.

Why is selecting the right valve bag important for the filling process?

Choosing the correct valve bag is crucial to optimize the efficiency of the filling machine. It ensures that each bag is filled to the optimal level, minimizing waste and enhancing the overall consistency and reliability of the packaging process.

How do automatic valve bag fillers minimize wastage and ensure consistent bag weights?

Our bag fillers come equipped with advanced technology that directs materials efficiently into the bags, reducing spillage. The automatic valve mechanism ensures each bag is filled accurately, maintaining consistent weights and minimizing material wastage.

REQUEST A QUOTE!

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed