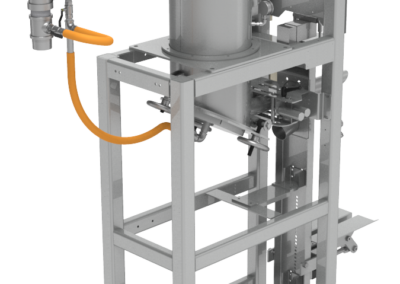

Digital Forced Air Valve Bag Filler

Model 7300

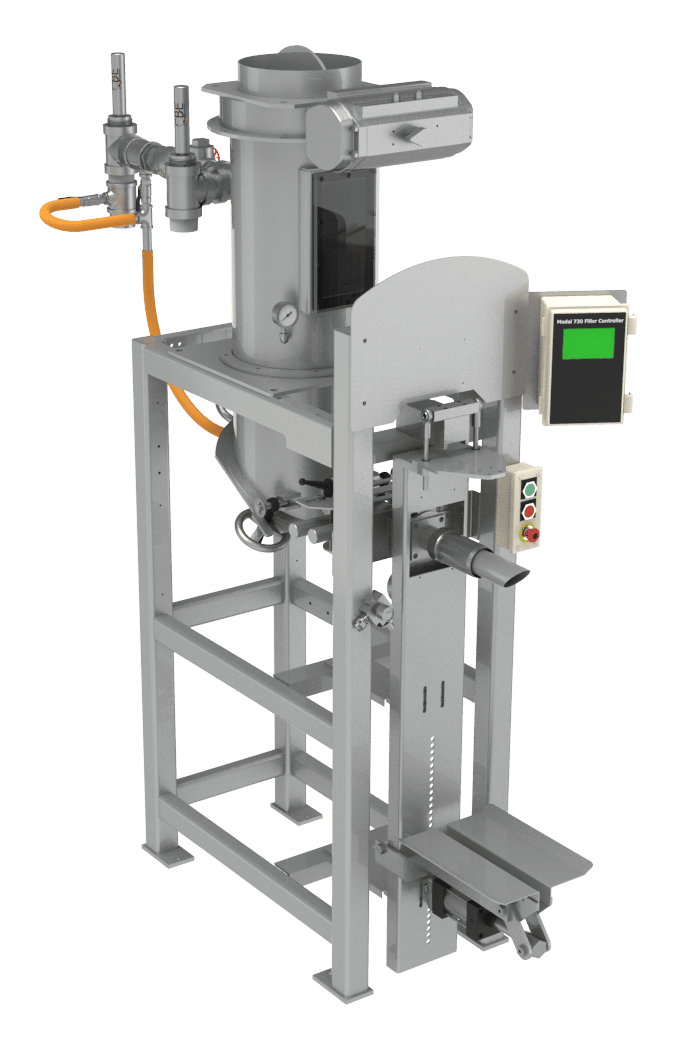

Model 7300 Digital Forced Air Valve Bag Filler is a heavy-duty machine designed for materials that may compact, clump or require gentle handling. It simultaneously pressurizes and fluidizes products. Fewer internal moving parts in the machine have contact with materials, thus creating a smoother flow and greatly reducing the potential for degradation. It is also very easy to open and clean between production runs of different grades or types of material. The 7300 is intended for rugged and continual use with little maintenance.

Click Images for Larger Views

Click to View Videos

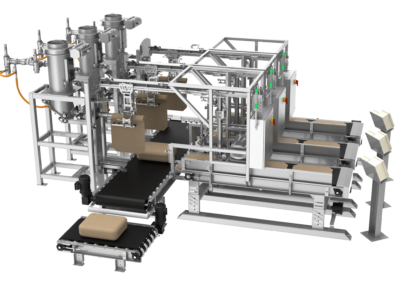

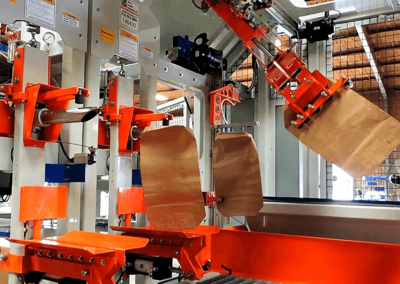

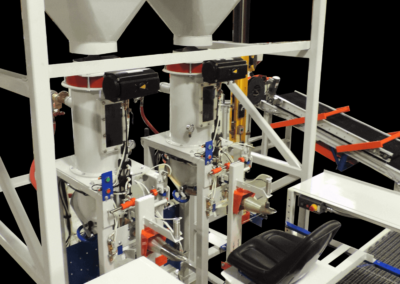

Model 7300 Bagging Barite with Automatic Bag Placer

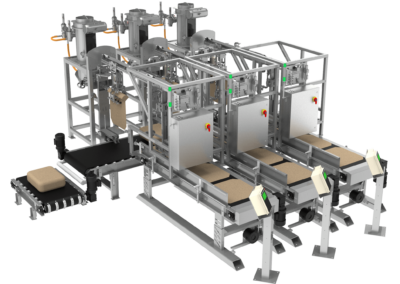

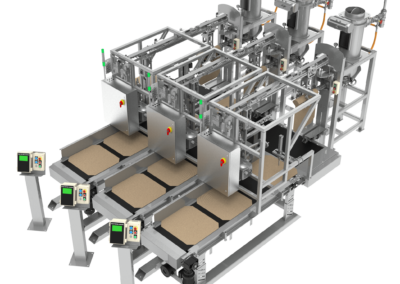

Model 7300 Bagging Mortar w/Bag Placer, Turning Conveyor, & Robotic Palletizer

Model 7300 Bagging Sodium BiCarbonate

Model 7300 with Robotic Bag Placer

Examples of Materials Bagged with this Machine

Mortars, hydrated lime, gypsum, bentonite, barite, pigments, fertilizer, plastic pellets, plastic resins, calcium carbonate, starch, corn flour, oat flour, powdered sugar, hard grains

Granules

Powders with fine granules

Flakes

Specifications:

Bag filling weight range: 20-110 lbs. (9-50 kg)

Production rate: 1-10 bags per minute (material and bag size dependent)

Material density range: 30-150 lbs. (13.6-68 kg) per cubic foot

Operating modes: Semi- (operator assisted) or fully automatic

Bag types: Internal sleeve and/or tuck-in sleeve perforated paper, plastic film, and poly woven bags

Note: Product testing may be required to determine actual bag filling and bag weight accuracy.

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed