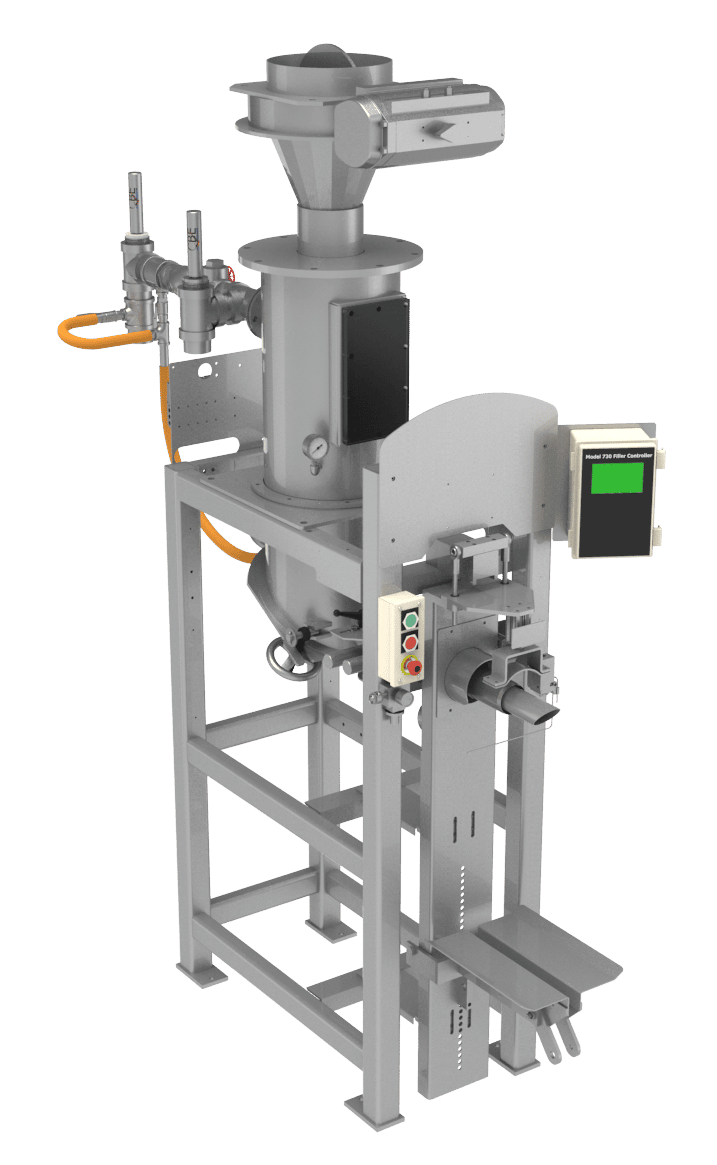

Abrasive-Duty Forced Air Valve Bag Filler

Model 7200

The Abrasive-Duty Forced Air Valve Bag Filler is a high-output machine designed to bag many different types of abrasive materials. It requires only a minimal amount of maintenance and is extremely durable. Model 7200 is constructed with continuously welded thick wall box steel tubing for rugged and continual use. A specially designed inlet valve allows it to cycle without internal moving parts. Material can be cleared using a secondary air valve without opening the machine.

Click to View Videos

Model 7200 with Model 2700 Automatic Bag Placer

Model 7200 Bagging Concrete with Bag Picker & Robotic Bag Placer

Examples of Materials Bagged with this Machine

Sand, garnet, concrete, stucco, limestone, granulated sugar, granulated salt, calcium carbonate

Powders with fine granules

Specifications:

Bag filling weight range: 20-110 lbs. (9-50 kg)

Production rate: 1-10 bags per minute (material and bag size dependent)

Material density range: 50-150 lbs. (23-68 kg) per cubic foot

Operating modes: Semi- (operator assisted) or fully automatic

Bag types: Internal sleeve and/or tuck-in sleeve perforated paper, plastic film, and poly woven bags

NOTE: Product testing may be required to determine actual bag filling rates and bag weight accuracy.

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed