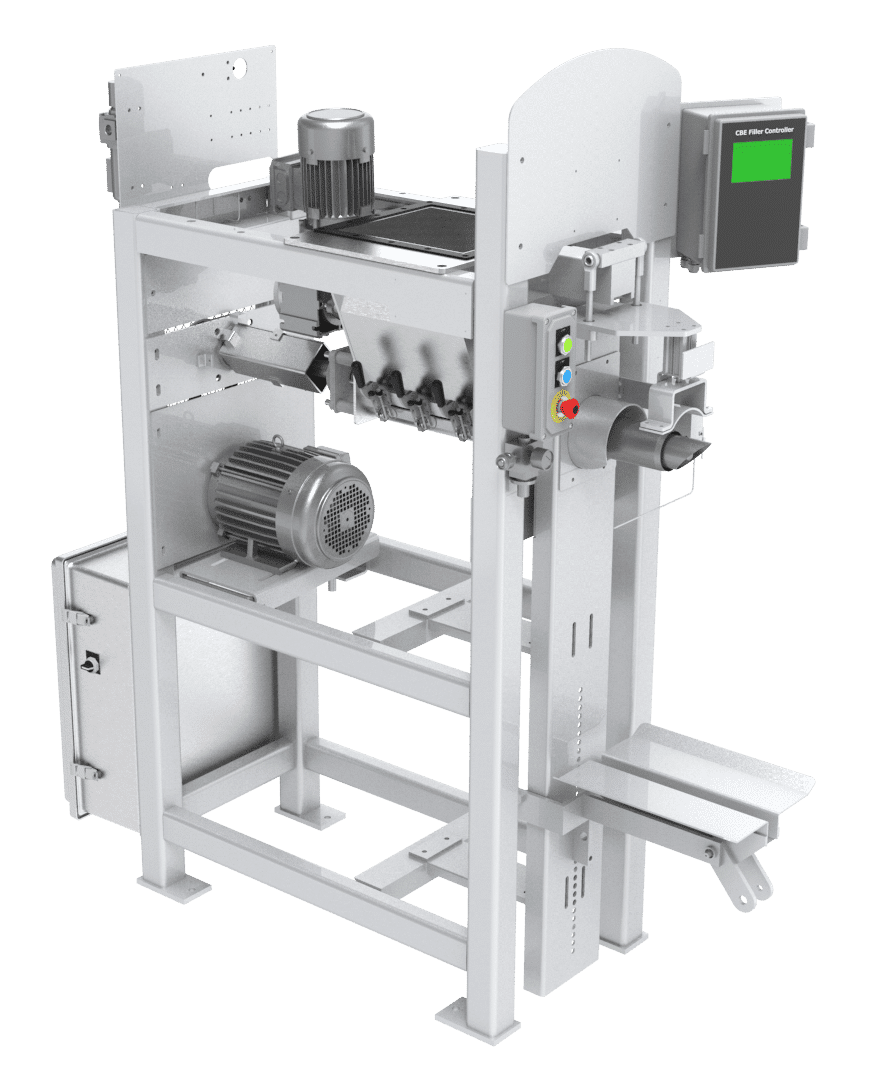

Valve Bag Filling Machine

Valve bag filling machines represent the pinnacle of efficiency and reliability in the industrial packaging sector. These machines are specifically designed to handle a wide range of materials, from chemical powders to agricultural products, providing businesses with a cost-effective solution to their bagging needs. Whether your operation involves construction materials or industrial minerals, these advanced systems ensure precision and speed, filling numerous bags per minute. Integrating a valve bag filling machine into your production line can enhance productivity and maintain product integrity, making it an indispensable asset for industries seeking optimal packaging solutions.

Brief Overview

A valve bag filling machine offers efficient, precise, and reliable solutions for industrial applications, especially in sectors like construction, agriculture, and chemicals. These advanced systems cater to various materials, ensuring accurate fills and high throughput. Key types include impeller fillers for fine powders, auger fillers for granules, and gravity fillers for free-flowing materials, each maximizing productivity and minimizing waste. With cutting-edge technology, these machines enhance packaging speed, reduce manual labor, and maintain product consistency. Investing in such systems from Choice Bagging Equipment ensures optimal efficiency, transforming your packaging process and reinforcing operational success.

Key Highlights

- Valve bag filling machines deliver precise, high-speed packaging for diverse materials, enhancing productivity and reducing waste.

- Impeller fillers excel at handling fine powders, offering efficient dust control and consistent fill rates.

- Auger fillers provide precise filling for granules, minimizing downtime with design flexibility for varied granule sizes.

- Gravity fillers efficiently manage free-flowing materials, ensuring accurate fill levels and energy savings.

- Advanced technology in valve bagging boosts bags per minute, improving accuracy and reducing operational costs.

Understanding A Valve Bag Filling Machine

Valve bag filling machines are pivotal to industries needing reliable and efficient packaging solutions. As essential components in automated packing systems, they streamline the process of handling bulk materials, offering significant advantages in terms of speed and accuracy. Various industries, such as agriculture and chemicals, benefit from their use. From powdery substances to granulates, these bagging machines ensure precise filling, promoting operational efficiency and minimizing waste. Through advanced designs, these machines cater to products ranging from industrial minerals to construction materials, thus maximizing productivity. For further details, visit our comprehensive resource on valve bag fillers.

What Materials Are Ideal for Valve Bagging?

Choosing the right materials for valve bagging is crucial to achieving optimal results. Bulk materials such as chemical powders and cement are ideal candidates for these systems. Valve bag fillers are designed to handle them with precision, ensuring minimal spillage and maximum fill accuracy. For industries that rely on finely granulated or powdered substances, pneumatic conveying is often employed, integrating seamlessly with the filling machines to maintain a clean, efficient operation. This tech minimizes dust particles, ensuring a tidy environment and reducing the risk of contamination. The versatility of valve bagging systems allows them to pack everything from lightweight agricultural products to denser industrial minerals. For companies that need reliable bulk packing solutions, automatic valve baggers offer consistency and high throughput, fulfilling diverse operational demands without compromising on quality. Also, the integration of conveyors with these bagging systems enhances productivity, as it streamlines bag handling and transport, ensuring a smooth workflow from start to finish. It’s crucial for businesses to choose equipment that aligns with their specific needs, optimizing their packing processes effectively. Want to see how advanced bagging technology can benefit your operations? Discover more about valve bag solutions on our Valve Bag Fillers page).

Types of Valve Bag Filling Machines

Valve bag filling machines are integral to efficient bulk materials handling across various industries. Understanding the types of these machines is key to selecting the right equipment for your operational needs. Each type offers unique advantages, from fine powders to granules and free-flowing materials, enhancing productivity and accuracy in packaging processes. This section will explore impeller fillers, known for their efficiency with fine powders; auger fillers, with their precision for granule materials; and gravity fillers, ideal for handling free-flowing materials. These diverse options ensure businesses have the flexibility to meet their specific packaging requirements.

Impeller Fillers: Efficient for Fine Powders

Impeller fillers are expertly designed to handle fine powdery substances with unmatched efficiency. These machines utilize a rotating impeller mechanism that gently propels fine materials through the filling process, ensuring precise and consistent fill rates. Industries dealing with chemical powders or finely milled minerals frequently employ valve bag fillers with impeller systems because they ensure minimal spillage and optimal dust control, a critical factor in maintaining a clean working environment. With their ability to handle a wide variety of powders, these machines are indispensable in industries like pharmaceuticals and construction, where accuracy and purity are paramount. Integrating impeller fillers into existing systems enhances the overall efficiency, seamlessly aligning with conveyors and other bagging systems. Businesses will find these machines particularly beneficial when high-level precision and speed are required, as they can fill numerous bags per minute, accommodating large-scale operations without compromising on the integrity or quality of the product. Choose impeller systems to elevate your powder packaging processes to new heights, ensuring superb packing efficiency.

Auger Fillers: Precision for Granules

In industries where granules such as seeds, grains, or small crystals are the primary products, auger fillers offer unparalleled precision in packaging. The auger fillers work through a helical screw mechanism, finely tuning the amount of product dispensed into each valve bag, making them ideal for consistent and repeatable fill cycles. What sets auger fillers apart is their capability to handle varying granule sizes with minimal adjustments needed, thus reducing downtime and increasing overall productivity. Their precision-driven designs prevent overfilling and underfilling, which is essential for maintaining product quality and packaging integrity. These filling machines can seamlessly integrate with larger bagging systems and conveyors, forming cohesive systems that streamline the packaging process. Using advanced sensors and controls, auger fillers ensure each bag is filled accurately, a critical feature for maintaining product standards in industries like agriculture and food processing. Businesses looking to refine their packaging processes will find auger fillers indispensable for achieving the highest precision with granulated products, optimizing their bagging operations efficiently.

Auger fillers not only excel in precision but also offer additional advantages that make them an optimal choice for packaging granulated products.

- Versatility in handling a wide array of product types and consistencies, from powders to granules.

- Easy to clean and maintain, minimizing downtime and maximizing efficiency.

- Adaptability with various container sizes and types, ensuring seamless integration into diverse production lines.

These features highlight the comprehensive capabilities of auger fillers, making them indispensable in modern packaging solutions.

Gravity Fillers: Ideal for Free-Flowing Materials

Gravity fillers are specifically designed to handle free-flowing materials such as rice, seeds, or plastic pellets, providing a straightforward yet effective solution for valve bagging. This method employs the force of gravity to feed material into valve bags, making it an energy-efficient option that reduces operational costs. Gravity fillers offer a user-friendly design, making them accessible choices for businesses looking to improve their bagging line without extensive training or expertise. Their simplicity does not detract from their capability; these fillers offer consistent output rates, ensuring each valve bag is perfectly filled. They excel at maintaining accurate fill levels, a critical aspect for companies prioritizing product standardization and quality assurance. When integrated into comprehensive packaging systems, gravity fillers work harmoniously with conveyors, allowing for a seamless flow of materials, which enhances throughput. They are often preferred by industries that process large volumes quickly due to their robust construction and reliability. Opt for gravity fillers to optimize your free-flowing material packaging, effortlessly meeting high-demand production targets.

Bagging Speed and Efficiency

Valve bag filling machines enhance productivity by offering remarkable speed and efficiency tailored to varied industrial needs. Essential for companies looking to process large volumes, these machines handle bulk materials with precision, ensuring each bag is filled accurately. By leveraging advanced technology, valve baggers optimize bagging speeds, enabling faster turnover and minimizing downtime. Industries from agriculture to construction rely on these machines to elevate their operations, effectively handling everything from chemical powders to industrial minerals. Discover how these technologies can transform your packing processes with our Model 7300 Forced Air Valve Bag Filler.

Maximizing Bags Per Minute with Advanced Technology

Utilizing advanced technology, valve bagging machines can significantly improve the number of bags filled per minute, crucial for industries aiming to boost efficiency. By integrating cutting-edge automatic systems, these machines enhance packers’ capabilities, optimizing the handling and filling processes. Technologies like modern conveyors streamline product handling, ensuring smooth movement through the bagging machines, thus maximizing output. The strategic use of these technologies allows for not only increased speed but also improved accuracy in bulk packaging, reducing waste and ensuring consistent product quality. Automatic fillers and packers are designed to adapt to various materials, from fine powders to denser substances, thereby providing versatile solutions for companies dealing with a range of products. Embracing these innovations means minimizing manual labor, which translates to lower operational costs and heightened efficiency. For businesses looking to stay competitive, maximizing bags per minute with advanced technology is more than achieving speed; it’s about enhancing the entire packing process. Investing in these systems equips your operation with equipment that keeps up with high-demand cycles. Explore our state-of-the-art [bagging solutions](https://www.choicebagging.com/valve-bag-fillers/model-730/) to enhance your efficiency and drive your business forward.

Key Features of Modern Valve Bag Filling Systems

Modern valve bag filling systems are designed to provide exceptional efficiency and precision in bulk packaging operations. With advanced technology, these systems cater to a variety of materials, ensuring accurate fills and reducing operational waste. Industries ranging from agriculture to manufacturing rely on these versatile machines to enhance productivity and consistency. The key features of these systems not only reduce costs but also boost performance, making them indispensable for companies looking to optimize their packaging processes. Discover how these machines can transform your operations, providing a smarter, greener approach to industrial packaging solutions.

Boosting Performance While Reducing Waste

In the quest for operational excellence, modern valve bag filling systems stand out by boosting performance while reducing waste. These systems are engineered to maximize filling accuracy, thereby minimizing material loss and ensuring consistent bag weights. Designed for diverse materials like chemical powders and agricultural products, the machines utilize state-of-the-art fillers and automatic control mechanisms to achieve precise fills every time. The integration of advanced conveyors further enhances these systems, providing a streamlined flow that minimizes downtime and increases throughput. By reducing manual handling, the systems cut down on labor costs, contributing to a more efficient packaging process.

The versatility of these valve bags makes them apt for various industrial applications, from construction to mining. With their robust construction and reliable operation, valve bagging machines are a critical component in creating a sustainable packaging environment. The automatic nature of the machinery ensures repetitive accuracy and consistent high-quality production. Furthermore, these systems are easily integrated into existing bagging systems, offering a seamless transition and adaptability. Companies embracing these solutions find a significant boost in performance, aligned with an eco-friendly approach by effectively reducing waste. Enhance your packaging line with choice bagging equipment and explore how you can maximize efficiency by visiting our advanced valve bag filling solutions.

Incorporating valve bag filling machines into your production line not only boosts efficiency but also ensures precision and reliability in packaging. These machines are tailored to handle various materials, from industrial minerals to chemical powders, meeting the demand for high-speed bagging with accuracy. By investing in a reliable valve bag filling machine from Choice Bagging Equipment, you’re enhancing productivity and safeguarding operational integrity. Explore our range today to discover how our solutions can streamline your packaging process and elevate your business to new heights.

Frequently Asked Questions

1. What are valve bag filling machines used for?

Valve bag filling machines are used in the industrial packaging sector to handle a wide range of materials, including chemical powders, agricultural products, construction materials, and industrial minerals. They ensure precision and speed, filling numerous bags per minute, enhancing productivity, and maintaining product integrity.

2. What types of valve bag fillers are available?

The main types of valve bag fillers include:

- Impeller fillers for fine powders, which offer efficient dust control and consistent fill rates.

- Auger fillers for granules, providing precise filling for varied granule sizes with design flexibility.

- Gravity fillers for free-flowing materials, ensuring accurate fill levels and energy savings.

Why should businesses invest in valve bag filling machines from Choice Bagging Equipment?

Investing in valve bag filling machines from Choice Bagging Equipment maximizes efficiency, transforms packaging processes, reinforces operational success, and enhances productivity. These machines offer reliability and cost-effective solutions tailored to various industrial needs, helping businesses maintain competitive operational standards.

How do valve bag filling machines enhance productivity?

Valve bag filling machines enhance productivity by offering high-speed packaging capabilities, ensuring precise filling, and optimizing bagging speeds. Advanced technology reduces manual labor, minimizes operational costs, and boosts the number of bags filled per minute, providing a strategic advantage in competitive industries.

What materials are suitable for valve bagging systems?

Valve bagging systems are suitable for numerous bulk materials such as chemical powders, cement, agricultural products, industrial minerals, and free-flowing products like rice or seeds. The integration of pneumatic conveying minimizes dust and ensures clean operational environments, optimizing the packing process for these materials.

REQUEST A QUOTE!

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed