A contract packager of blended cement and concrete mixes in western Arkansas was seeking to install a bagging system to bag Portland cement into 94 Lb. valve bags at a rate of 600 bags per hour (56,400 Lbs. / Hrs. or 25,636 KG). The client was looking for a system solution that would fill cleanly and be capable of discharging the filled bags bottom end first of the filling machine so that they would be automatically aligned with the in-feed to their existing bag palletizing system which was positioned directly to the left of the bag filling station just a few feet away.

CBE proposed a system designed to include vertical impeller packers featuring a specially designed bag discharge carriage that used parallel linkage to rock the bag back off the spout in a vertical orientation before lowering the bag onto a takeaway conveyor, bottom end first, that would take it away to the bag palletizer. Additionally, CBE equipped the machine with an inflatable bag seal and spout purge assembly that simultaneously prevented displaced dusty air from escaping the valve of the bag during the filling process and cleared the spout of the product after each bag fill. An integrated reclaim screw system located under the takeaway conveyor caught and automatically recycled it to the supply hopper so it could be packed again.

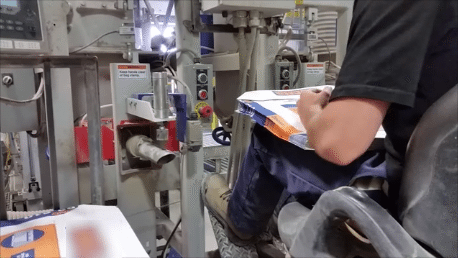

The system required one operator to place empty bags on the filling machine. A chair mounted on a pivoting arm allowed the operator to access the filling machines from a mezzanine located at the rear of the system without having to climb over the structure, ladders, or navigate over obstacles to mount the operator’s seat. He simply sat down on the chair at a natural height located over the mezzanine deck, pulled a lever to unlock the chair, and then pivoted out over the takeaway conveyor before re-engaging the lock to hold the pivot armchair in position. To dismount the chair, the operator simply reversed the procedure.

Recent Comments