Key Features & Benefits

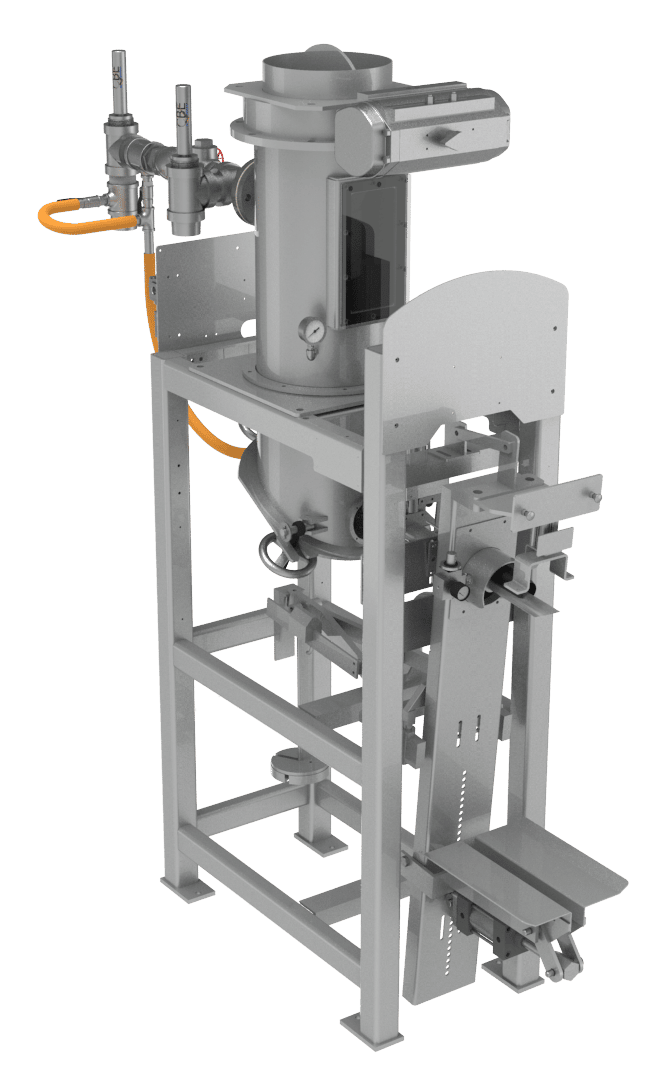

Mechanical Forced Air Valve Bag Filler – Model 7700

Time-tested, low-tech design that is easy to learn and operate

Designed for continuous, dependable bagging

Up to 3 machines can be paired together for increased production rates

Pivot beam mechanical scale for simple, fast weight adjustments

Handles a wide variety of materials and bag types

Pressure vessel automatically empties material after a run

Large, hinged door allows tool-free opening for rapid cleanout, inspection, and maintenance

Specialized pressure vessel with no internal moving parts conditions materials to flow smoothly

Standard Equipment:

Material contact surfaces are durable powder coated carbon steel

Butterfly inlet valve with heavy-duty pneumatic actuator

Pressurizing chamber with choice of 3.5 or 5 cubic foot capacity

3:1 ratio mechanical counterbalance weighing scale

Bulk only pinch valve cutoff

Single wall, fill spout (sized per customer requirement)

Air-operated clamp holds bags securely for no mess filling

Hinged drop bottom interior access door

Machine gray powder coat

Optional Equipment:

Tapered dust seal cone

Automatic bag discharger

Automatic fill start

304 stainless steel material contact areas

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed