Heavy-Duty Bulk Bag Filling Machine

Heavy-Duty Bulk Bag Filling Machine

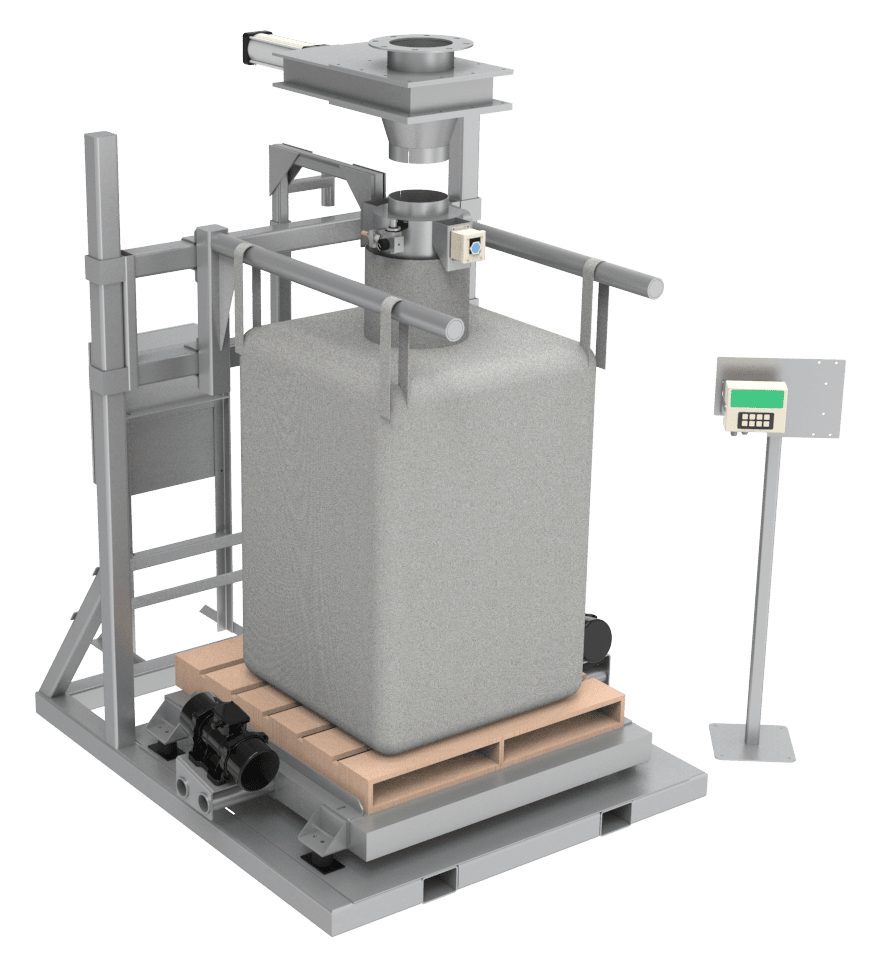

Model 5100

Ideal for applications with low to moderate production requirements. Configurable for a wide range of powders, flakes, and granules.

Examples of materials this machine bags: mortars, hydrated lime, gypsum, bentonite, barite, pigments, fertilizer, plastic pellets, plastic resins, calcium carbonate, starch, corn flour, oat flour, powdered sugar, hard grains.

Fills up to 10 bags per hour.

High-Speed Bulk Bag Filling Machine

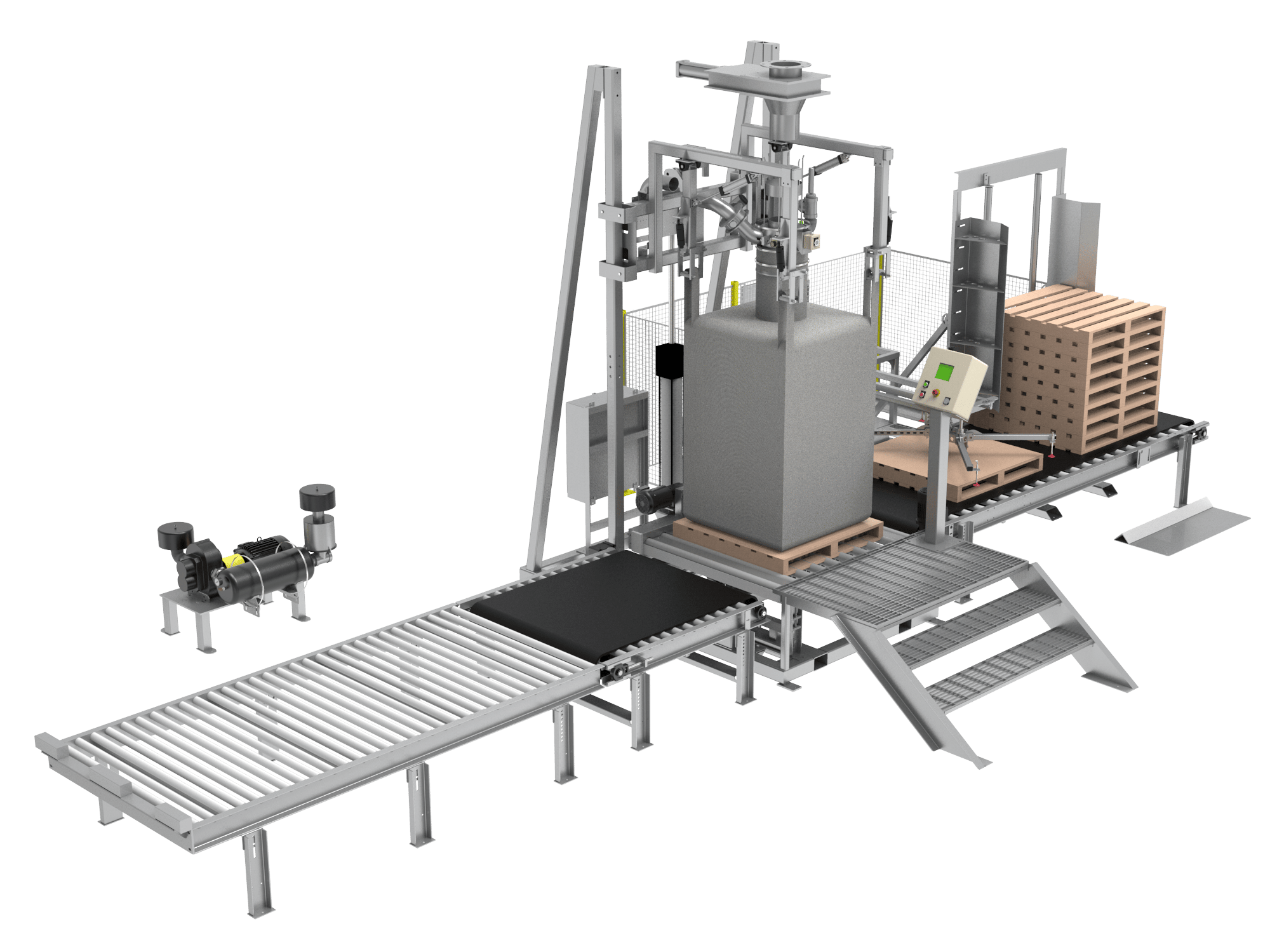

Model 5200

Examples of materials this machine bags: mortars, hydrated lime, gypsum, bentonite, barite, pigments, fertilizer, plastic pellets, plastic resins, calcium carbonate, starch, corn flour, oat flour, powdered sugar, hard grains.

Fills up to 25 bags per hour.

In manufacturing and processing facilities, inefficient packaging systems can lead to production slowdowns, wasted product, and increased labor costs. When it comes to filling large-format bags like FIBCs or Super Sacks, the need for precise, reliable, and fast equipment is critical. That’s where the right solution can make all the difference—improving productivity while minimizing downtime.

Solving the Problem With a Trusted Solution

Choice Bagging offers a dependable and effective answer to these challenges with our bulk bag filling machine solutions. Designed with performance in mind, our machines help streamline the bagging process, reduce material loss, and boost throughput. With decades of experience and a commitment to quality, we manufacture equipment that simplifies even the most complex filling operations.

Relying on Expertise Since 1978

Since 1978, Choice Bagging has manufactured top-tier bagging systems, including bulk bag fillers that meet the demands of rugged industrial environments. Our machines are built to last, with minimal moving parts, user-friendly controls, and built-in diagnostic tools that make maintenance easy. Whether you’re working with powders, granules, or other free-flowing materials, our systems are engineered for precision and consistency.

Built to Perform in Demanding Environments

We build every bulk bag filling machine to operate reliably, even under tough conditions. From manual to fully automated setups, each system is customized to fit the specific needs of your facility. Our focus on durability and long-term performance ensures that your investment continues to deliver results year after year.

Partnering for Long-Term Success

We don’t just deliver equipment—we stand behind it. Our expert support team is always ready to assist with training, troubleshooting, and routine maintenance. It’s our goal to keep your systems running smoothly with minimal interruption.

If you’re ready to increase efficiency and reduce packaging headaches, let’s talk. Contact Choice Bagging today to learn more about our bulk bag fillers and find the right solution for your operation.

REQUEST A QUOTE!

What is a Bulk Bag Filler?

What Types of Bulk Bag Fillers are there?

The two classes of bulk bag fillers are suspended “hanging” fillers and bottom supported “platform” fillers. Both can be built with either a gross or net weigh scale. Gross weigh scales simultaneously fill and weigh bags, while net scales pre-weigh and fill as a secondary step. Lastly, most bulk bag fillers are gravity fed by slide-gate or butterfly valve, or fed by rotary valve or auger.

Examples of Materials Packaged with Bulk Bag Fillers:

Building Materials

Cement, Concrete, Flyash, Mortars, Hydrated Lime, Plaster, Refractories, Sand, Gravel

Industrial Materials

Calcium Carbonate, Kaolin Clay, Talc, Alumina, Graphite, Barite, Bentonite, Gypsum, Coal

Industrial Chemicals

Plastic Pellets, Fertilizer, Pigments, Zinc Oxide, TIO2, Iron Oxide, Carbon Black

Food Products

Wheat Flour, Corn Flour, Oat Flour, Sugar, Salt, Spices, Cake Mixes, Cocoa Powder

Agricultural

Animal Feed, Corn, Soybeans, Seed, Feed, Fertilizer,

Wood Pellets

Capabilities of Bulk Bag Filler Systems

Choice Bagging bulk bag fillers can package 1,000 to 4,400 lb (454-2,000KG) bags. The materials they support include non-dusty powder, flaked, or granular products. They can also run at production speeds of up to 25 bags per hour.

Finding the Right Bulk Bag Filler

Choosing the proper bulk bag filler can be difficult because so many factors need to be considered. These include the bag type you’re using, the speed at which you need them filled, and your budget. All of these elements and more will influence your decision. However, the good news is that bulk baggers can be customized to meet almost any need you may have. Contact Choice Bagging today and let us simplify the process of finding the right machine for you!

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed