It’s not surprising that pressure is an important factor in bagging dry bulk powders; for a cement bagging machine or concrete bagging machine, it is especially critical to speed and weight accuracy. This article explains how one customer significantly improved productivity and accuracy by following the fundamentals.

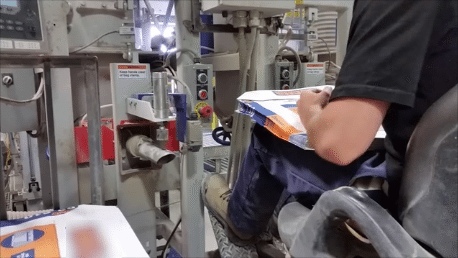

Our Model 730 Pressure Flow Air Packer is one of the most popular concrete and cement bagging machines on the market today. We recently installed a pair of Model 730 Pressure Flow Air Packers to bag concrete and mortar mixers at a dry mix plant in Montreal, Canada.

Shortly after installation, the customer called to say that the weight accuracy was not within weight tolerance and also that the concrete bagging rate was much slower than expected. Additionally, the machine is designed to empty out completely at the end of a production run but for some reason, he reported that when these machines would empty down to its last 2-3 bags of material, it would completely stop flowing out of the machines.

This was a problem because the customer made very small batches of product and had very frequent product grade changeovers that required opening and completely cleaning the interior of the machine between batches. This meant that in nearly every batch, the customer would have to open the chamber and dump 100-150 pounds of material creating waste and extra cleanup time. Our customer asked that I come to the plant to evaluate the machines and determine whether they had some kind of mechanical or electrical problem. The presumption was that there must be some sort of internal problems with the filling machines.

Mysteriously Slow

Upon arrival at the plant, it was quickly apparent that there was a problem. Although at that moment, bag weight accuracy was within specification, the bags were taking unusually long to fill. All of the mechanics of the machine and the controls were operating as designed, but the product was taking too much time to load into the bag. Looking at the pressure gauge on the side of the chamber, I noticed that it registered no pressure. So I began a diagnostic analysis of the chamber and its pressurizing system which consisted of the pressurizing chamber, the air pad, and the blower control valve that regulating the inlet of high volume, low-pressure air into the machine.

Looking for Obstructions

I looked for obstructions in the flow of air to the air pad the fluidized the material and also the disseminator that provided the pressurizing air to drive the air with force down and out of the machine. Neither had any obstructions but neither were flowing the amount of air needed to fill a bag properly.

Checking the Low Pressure Blowers

Then I asked to see the low-pressure blowers that were supplied with the machines. Our blowers are specially designed to provide high volume, low-pressure air to provide the pressurizing and fluidizing air required for the machines to operate properly. At this point, I learned that the blowers had not been installed. Instead, the old set of blowers from the previous set of baggers that ours had replaced were left in place and used to feed air to our machines. I asked to see them.

The first thing I noticed is that they were exceptionally old and smaller than the blowers that we had provided. Additionally, the relief valves that prevented the old blowers from over-pressuring when not filling bags had been modified by someone at the plant to vent off half of the air that the blowers could generate before that air was even transferred over to our machines.

I asked what it would take to shut the line down to exchange the old blowers out for the new ones. This was not possible as the customer was in the middle of a campaign and this was their busy season. I told the customer that without knowing the exact condition of the old blowers there would be no way to assure that we could generate the volume of air and pressure required to achieve the results he was looking for.

Modified Relief Valves Restricting Air Flow

He asked me to see what I could do. I went back to look at the blowers. I noticed that the reason the relief valves had been modified was that they were worn out and someone had done their best to rig them to keep them going. Replacing them was the first order of business. I asked to see the pumps we had provided. I Compared the relief valves on our pumps to the relief valves on the old pumps. Fortunately, with some simple plumbing changes, our pressure relief valves are able to be retrofitted to the old blowers. Once I replaced the reliefs, we were able to hold steady pressure at 5 PSI although the volume was still much slower than optimal.

I then switched my attention to the Model 730s. They were designed to divide the flow of incoming air from the low-pressure blowers and direct the bulk of the air to the upper half of the pressurizing chamber to utilize as pressurized air and the remainder down to the bottom of the machine to provide fluidizing air to lift and convey the material into the bag. Realizing that the old pumps were not capable of generating the volume of air required to both pressurize and fluidize simultaneously, I shut off completely the pressurizing air and directed the entire airflow to the air pad to fluidize the material. Although this solution had its own drawbacks, the machines were now capable of filling bags at a respectable pace, and bag weight accuracy was improved.

Puzzling Weight Fluctuation

We began to run and check to weigh all of the bags coming down the line to the bag palletizing system. We would see that the bag weights would begin good but then the weights would begin to drift after a period of time. At this point, I asked what the minimum level of the product was required to be maintained above the machine for it to be allowed to run. I was told that there was no minimum standard. I then asked what type of level controls were in the bin to indicate to the operator how much material was in the bin at a given time. I was told there were level sensors in the bin but they were not visible to the machine operator and were only used to signal the blending system when there was room in the bin for the next batch of product.

Maintaining Head Pressure

I told the client that especially without the blower capable of generating pressurizing air to generate artificial head pressure in the filling machine, that maintaining product head pressure of the product above the machine would be imperative to maintaining good filling speed and weight accuracy. Varying head pressure is very important as changing head pressure changes how the product flows and how the product flows (and at what rate and consistency) directly affects bag weight accuracy. I then trained the system operators to manually monitor the level of product in the supply bin and to stop filling bags when the level of product in the bin got low. This did not cause a production problem as the Model 730’s were capable of bagging much faster than the blending process was able to make new products.

With these changes in place and the customer now aware of how to compensate for the lack of air pressure and head pressure, the results improved dramatically. Bag fill times averaged 5 seconds per bag per spout on 30 KG (66 Lb) bags and weight tolerance averaged +/- .25-.5% depending on the grade of material packaged.

Paying attention to how to properly install and set up a cement bagging machine (or any other application) is critical. Installing a bagging machine is not simply a matter of sliding it under a supply bin and connecting it to utilities. It must be supplied with a good and consistent flow of material and especially if this is not possible, then assuring that the machine has good access to an adequate air supply is even more critical. And if these fundamentals are not fully understood, then it is advisable to seek the help and advice of someone who can help get the fundamentals right. Failing to pay attention to the details or work with someone will be costly and cause results to suffer.

Recent Comments