Bulk bag fillers, also known as FIBC fillers, are vital in efficiently packaging and transferring dry powders and bulk solids across multiple industries. From agriculture to construction, these machines ensure that materials are safely and accurately loaded into Flexible Intermediate Bulk Containers (FIBCs). Among the leading manufacturers in this space, Choice Bagging Equipment has earned a reputation for delivering durable, high-performance fillers designed to optimize productivity and reduce waste. In this guide, we’ll explore the top five bulk bag fillers available today, along with key features, considerations, and maintenance tips to help you choose the right solution for your operation.

Overview of Bulk Bag Fillers

Bulk bag fillers are specialized machines designed to handle the transfer of bulk materials such as powders, granules, and pellets into large woven bags or FIBCs. The process of filling these large bags with bulk materials is known as bagging, and it is a key application of these machines. These fillers are vital across many sectors, including food, pharmaceuticals, and chemicals, where high-volume packaging and transport are necessary. Their primary functions encompass precision filling, dust control, and ease of use, which collectively contribute to efficient production lines.

Benefits of Using a Bulk Bag Filling Machine

Implementing a bulk bag filling machine in your operation brings a host of advantages that can transform the way you handle bulk materials. One of the standout benefits is the ability to achieve efficient filling, allowing businesses to fill bulk bags rapidly and with remarkable accuracy. This not only streamlines the bag filling process but also reduces labor requirements and operational costs. Bulk bag fillers are engineered for equipment effectiveness, delivering reliable and consistent performance with minimal downtime, which is crucial for maintaining high productivity levels.

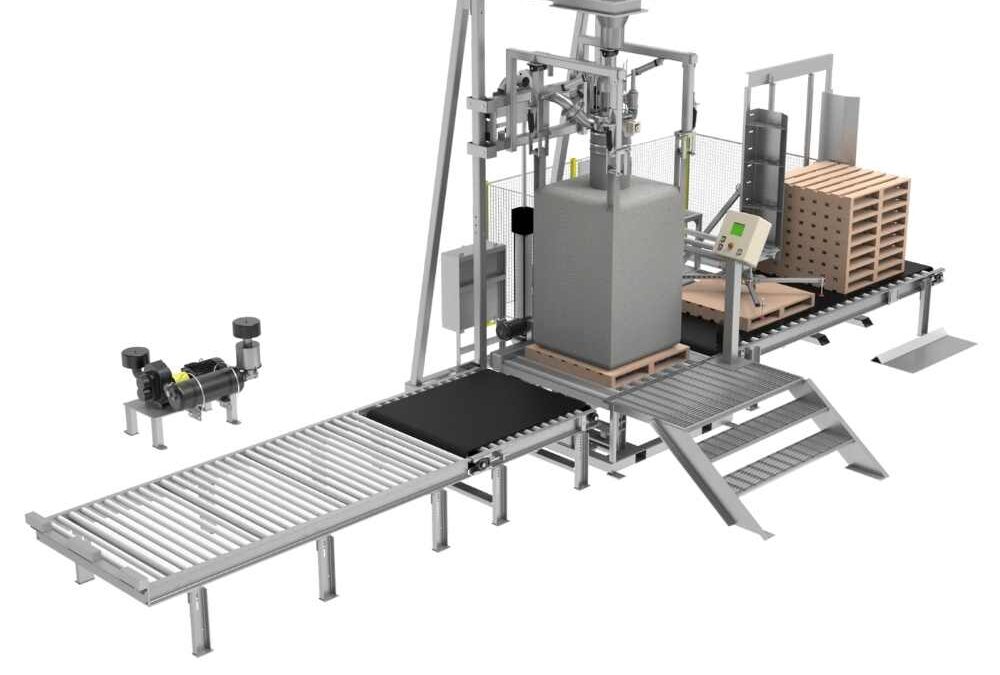

These machines are designed for high performance operation, capable of handling a diverse range of dry bulk products, from powders and granules to more challenging materials. By automating the filling process, companies can ensure that each bag is filled to the correct weight, enhancing product quality and reducing material waste. Safety is another key advantage, as bulk bag filling machines minimize manual handling, lowering the risk of workplace injuries. Additionally, these systems can be seamlessly integrated with roller conveyors and pallets, creating a comprehensive bulk bag filling system that supports efficient material flow throughout your facility. With their robust construction and low maintenance requirements, bulk bag filling machines are a reliable investment for industries seeking consistent, high-quality results.

Key Components of a Bulk Bag Filling Station

A well-designed bulk bag filling station is composed of several essential components that work together to ensure a secure, efficient, and precise filling process. At the heart of the system is the fill head, which directs material into the bulk bag with controlled flow. The bag spout forms a tight, secure connection between the fill head and the bag, preventing spills and ensuring that the material is delivered exactly where it’s needed. Bag loops are used to suspend the bag safely during filling, providing stability and support as the weight increases.

To further enhance the process, a bag inflation system is often included, inflating the bag before filling begins to ensure it maintains its shape and can accommodate the full volume of material without damage. Load cells are integrated to monitor the weight of the material as it fills the bag, allowing for precise control and consistent results. Advanced control systems manage the entire operation, regulating the flow of material and ensuring that each bag meets the required specifications. Additional features, such as dust collection systems and operator safety devices, are typically incorporated to maintain a clean, safe, and efficient work environment. Together, these components make the bulk bag filling station a reliable and high-performance solution for handling bulk materials.

Key Features of Effective Bulk Bag Fillers

Effective bulk bag fillers come equipped with several essential features to ensure optimal performance:

- Fill Accuracy: Precision weighing and dispensing systems allow for exact material quantities, minimizing waste and enhancing product quality.

- Versatility: The ability to handle different materials and bag sizes—including adjustable width to securely accommodate various bag dimensions—makes these fillers adaptable to a variety of applications.

- Dust Control: Integrated venting or extraction systems help maintain a clean work environment and comply with safety regulations.

- Automation: Options range from manual setups to fully automated machines, catering to diverse operational needs.

- Ergonomics and Safety: Features like tilting fill heads and secure bag clamps enhance usability and worker safety.

Our Top Five Bulk Bag Fillers

Identifying the right bulk bag filler can greatly enhance your production capabilities. Some of the top five options include basic models that are cost-effective and ideal for straightforward or small-scale applications. Here are five of the best options available:

-

FIBC Fillers

FIBC fillers use a carousel or conveyor system to efficiently fill bags with granules, powders, and flakes. They are known for high-speed filling, accurate dispensing, and effective dust control, making them ideal for large production volumes.

In typical bulk bag filling applications, FIBC fillers can process between 20 to 40 bags per hour, depending on the material and system configuration. These types of bulk bag fillers are the ones that we actually use, we have two types, our Model 5200 which is highly automated and our fastest bulk bag filler and our Model 5100 which is smaller but adaptable, great for small businesses. Check them out for more details on how they can be applied to your process.

-

Auger Fillers

Utilizing an enclosed screw conveyor, auger fillers are intended for the precise filling of powders and fine granules. They dispense material with precision and are particularly suited for these applications, offering exceptional control, especially in batching applications.

-

Gravity Fillers

These simple machines are constructed with simplicity and durability in mind, leveraging gravity to fill containers from a hopper or bin. Best for free-flowing, coarse materials, gravity fillers are low-maintenance and help quick setups, making them a reliable choice for many operations.

-

Vacuum Fillers

Using air pressure, vacuum fillers ensure gentle handling of fragile or light materials. They are perfect for delicate products as they minimize damage during the filling process while maintaining efficiency.

-

Net Weight Fillers

Net weight fillers dispense materials until a set target weight is achieved, ensuring accuracy across diverse materials. They are invaluable in applications requiring consistency, such as food recipes or chemical formulations, and are especially useful in bulk bag filling applications where precision and consistency are critical.

Applications of Bulk Bag Fillers

Bulk bag fillers are indispensable across a wide spectrum of industries, thanks to their versatility and efficiency in handling bulk materials. In food processing, these machines are used to fill bulk bags, super sacks, and flexible intermediate bulk containers with ingredients like flour, sugar, and grains. The chemical and pharmaceutical sectors rely on bag fillers to package powders, granules, and pellets safely and efficiently, ensuring product integrity and compliance with strict industry standards.

In agriculture, bulk bag fillers streamline the packaging of seeds, fertilizers, and animal feed, while the mining industry uses them to handle materials such as sand, gravel, and cement. Construction and landscaping companies benefit from these machines when filling bags with soil, mulch, or other materials for transport and application on job sites. Bulk bag fillers are also used to fill gaylord boxes, totes, and other containers, making them a flexible solution for a variety of packaging needs. By improving efficiency, reducing labor costs, and enhancing safety, bulk bag fillers play a critical role in modern bulk material processing and shipment operations.

Factors to Consider When Choosing a Bulk Bag Filler

Selecting the right bulk bag filler involves careful consideration of several factors:

- Material Type: Understanding the characteristics of the materials you will be filling, such as their flow properties, helps in choosing the right technology.

- Fill Speed and Automation: Assess your production demands and choose between manual or automated systems to match your efficiency requirements.

- Bag Specifications: Consider the size and liner needs of the bags you’ll use, as well as how they will be palletized post-filling.

- Dust Control: Review dust management features to ensure compliance with safety regulations and maintain a clean workspace.

- Changeover Frequency and Budget: Choose a filler that accommodates the frequency of material changes while aligning with your budget and maintenance capabilities.

- Roller Conveyor Integration: Consider the option to integrate a roller conveyor with your bag filling equipment for easier movement and palletizing of filled bags.

Maintenance and Best Practices for Bulk Bag Fillers

Routine maintenance is essential for maximizing the lifespan and performance of your bulk bag fillers. Here are some best practices:

- Regular Inspection: Frequently check and replace wear parts, especially components like seals and augers that undergo significant wear. Inspect the discharge spout or discharge outlet for signs of wear and ensure proper function to maintain efficient material flow.

- Dust Management: Ensure that dust control systems are fully operational to prevent build-up and maintain a clean environment.

- Calibration: Periodically calibrate weighing and dispensing systems to maintain accuracy in filling processes.

- Cleaning and Checks: Keep all machine components clean and inspect for blockages or leaks to prevent downtime.

Investing in the right bulk bag filler can be a game changer for your operation, improving efficiency, safety, and product quality. With a variety of options available, understanding the features, benefits, and maintenance practices of these machines is vital. By selecting a filler that aligns with your specific needs and implementing best practices, you’ll ensure that your filling operations run smoothly and effectively.

Troubleshooting and Support for Bag Fillers

Ensuring the ongoing performance and reliability of your bulk bag fillers requires a proactive approach to troubleshooting and support. Common challenges, such as bag tears, material spills, or equipment malfunctions, can disrupt operations if not addressed promptly. Having a dedicated support team is essential—they can provide timely maintenance, repairs, and operator training to keep your equipment running smoothly.

Many suppliers offer a comprehensive range of parts and accessories, including replacement bags, fill heads, and control systems, to help extend the lifespan of your machines and maintain optimal performance. Technical support services are also available to assist operators with troubleshooting and to ensure that the filling process remains precise and consistent. By investing in regular maintenance and leveraging expert support, companies can minimize downtime, enhance equipment reliability, and maintain efficient, high-quality bulk bag filling operations.

Frequently Asked Questions about Bulk Bag Fillers

What are the top five bulk bag fillers available on the market?

The top five bulk bag fillers include FIBC fillers, auger fillers, gravity fillers, vacuum fillers, and net weight fillers, each designed for specific material types and operational needs.

How do FIBC fillers enhance efficiency in bulk bag filling?

FIBC fillers utilize carousel or conveyor systems for high-speed filling, ensuring accurate dispensing and effective dust control, ideal for large production volumes.

What should I consider when choosing a bulk bag filler?

Consider factors such as material type, fill speed, automation needs, bag specifications, dust control features, and your budget to select the right bulk bag filler.

Why is dust control important in bulk bag fillers?

Dust control is crucial for maintaining a clean work environment and complying with safety regulations, preventing potential hazards during material handling.

How can I maintain a bulk bag filler for optimal performance?

Routine maintenance includes regular inspections, dust management, periodic calibration of weighing systems, and ensuring all components are clean and functional. It is also important to inspect the annular gap in the discharge spout, as this gap controls airflow during bag filling and inflation, ensuring proper bag inflation and stability throughout the filling process.

Can vacuum fillers be used for fragile materials?

Yes, vacuum fillers are ideal for handling delicate or light materials since they minimize damage during the filling process while maintaining efficiency.

Recent Comments