If you’re in the market for advanced bagging solutions, open mouth baggers from Choice Bagging Equipment offer a range of options tailored for efficiency and productivity. These machines are perfect for handling diverse materials, from free-flowing powders to granular substances, in various packaging formats—including open top boxes, bags, drums, and totes. Highly versatile, they can adapt to different packaging needs and container types with ease. In this guide, you’ll discover five exceptional open mouth baggers and their benefits, designed to meet your specific needs and make your bagging process efficient and effective.

Understanding Open Mouth Bagging Machines

Open mouth baggers are perfect for packaging applications across various industries, including agricultural, chemical, and food sectors. These machines are designed to fill sewn, heat-sealed or various other types of bags in a range of materials and packaging, from light powders to more substantial granules. Their versatility is complemented by high-speed operation and customizable features to handle your unique packing requirements seamlessly. These machines can also be integrated into complete packaging systems for enhanced automation, allowing for seamless connection with conveyors, bag sealers, and palletizers. The operator plays a crucial role in managing the machine’s operation, ensuring correct bag placement, activation, and monitoring of the filling process.

Key features of open mouth baggers typically include touch screen controls, compact vertical footprints, and mobile designs. They can fill multiple bags simultaneously, efficiently handling various products to maximize throughput and efficiency. Also, they offer limited aeration during the filling process, reducing material waste and transport costs.

Bag Filling Process

The bag filling process is at the heart of any open mouth bagging system, ensuring that products are packaged efficiently, accurately, and with minimal waste. Open mouth bagging machines are designed to streamline this process, making them indispensable for operations handling a wide variety of materials, from free flowing granular products like grains and fertilizer to more challenging substances such as wood chips and cake mix.

The process begins with the placement of an empty bag—whether it’s a plastic open mouth bag, paper bag, or poly bag—onto the fill spout of the open mouth bagging machine. The bag is securely clamped in place, ready to receive the product. Material flows from a supply hopper through a funnel spout into the open mouth of the bag. The flow of material is carefully controlled by the bagging machine to ensure each bag is filled to the precise target weight.

Open mouth bagging machines can be equipped with either net weigh scales or gross weigh scales, depending on the specific requirements of the operation. Net weigh scales pre-weigh the material in a separate hopper before discharging it into the bag, offering high weight accuracy and faster fill rates. Gross weigh scales, on the other hand, weigh the material as it is being filled directly into the bag, which can be ideal for certain products and packaging needs.

To accommodate different types of materials and achieve optimal flow, open mouth bagging machines may utilize a variety of feeders, such as auger feeders for powders, belt feeders for free flowing products, or vibratory feeders for delicate or irregular materials. This versatility allows the system to handle everything from pet food and fertilizer to sand and nuts, ensuring consistent performance across a range of bag types and product characteristics.

Modern open mouth bagging machines are typically fully automatic, managing the entire fill cycle—from bag placement and filling to achieving the desired weight and releasing the filled bag for sealing. The fill rate and weight accuracy can be adjusted to suit the specific product and packaging requirements, ensuring that each bag meets quality standards and regulatory guidelines.

Once the bag is filled to the desired weight, it is released from the fill spout and moves on to the sealing stage, which may involve sewing, heat sealing, or pinch bag closing, depending on the bag material and application. This seamless integration of filling and sealing helps maintain product integrity and maximizes operational efficiency.

In summary, the bag filling process for open mouth bags is a critical component of any packaging operation. By leveraging the advanced features of open mouth bagging machines—such as precise weighing, adaptable feeders, and automated controls—manufacturers can achieve high-speed, reliable, and accurate packaging for a wide variety of products and bag types. Whether you’re working with plastic open mouth bags, paper bags, or poly bags, a well-configured open mouth bagging system is essential for meeting production goals and delivering quality products to your customers.

1. Model A: Versatile Performance for Diverse Applications

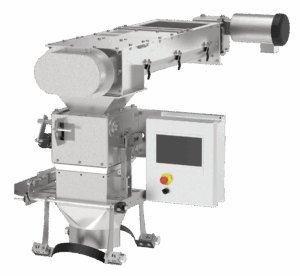

The Model NWB-AF (Twin Auger Open Mouth Bag Filler) from Choice Bagging Equipment stands out as a top choice for versatile applications. This machine is engineered to handle bag weights ranging from 20 to 110 lbs, accommodating a variety of products like powders and granules, as well as feed and pellets.

Key Features:

- Fills bags at a speed of 1 to 12 bags per minute, depending on the material.

- Compact design allows for easy integration into existing production lines.

- Options for multiple pallet types and customization to fit your specific operational needs.

Whether you’re packing fertilizers, pet foods, or industrial powders, the Model NWB-AF ensures precise weighing and efficient filling.

Score: 4/5

Model B: Reliable and User-Friendly

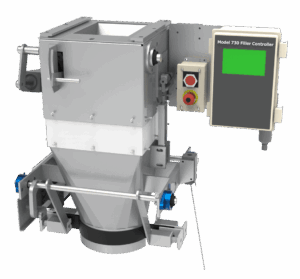

The Gravity Open Mouth Bag Filler – Model GB is expertly designed to efficiently bag granulated, free-flowing materials in low production runs. During operation, the product is discharged into the bag with precision and efficiency, ensuring accurate and consistent packaging. Its user-friendly and dependable operation makes it a top choice for many.

Highlights:

- Equipped with a pivot beam mechanical scale and weight indicator for precise adjustments using counterweights.

- Simple pull lever controls facilitate secure bag attachment and allow for quick adjustments to filling accuracy and speed.

- Operates without electricity or compressed air, enabling installation and use in virtually any location.

- An air-operated clamp securely holds bags weighing up to 70 lbs from the loading spout.

This model is ideal for businesses seeking reliable and efficient bagging solutions.

Score: 5/5

Model C: High scale for high density produce

The Digital Gravity Open Mouth Bag Filler Model GWB is engineered for efficiency in packaging medium to high density granulated, free-flowing materials at moderate speeds. Its user-friendly design ensures reliability and precision. The three-position gravity gate allows for optimal material flow. Product flows are managed using gravity-assisted feeding, ensuring consistent and accurate filling by maintaining a controlled movement of materials into the bagging mechanism.

Key Features:

- Gravity-operated mechanism for consistent filling.

- Digital display for accurate weight measurements within tolerances.

- Air-operated functions for rapid bag filling cycles, enhancing production speed.

This model is ideal for operations requiring secure handling of up to 60 lb. bags, with its air-operated clamp providing stability during the filling process. The three-position gravity gate allows for precise control over material flow, making it suitable for high-volume environments while ensuring easy maintenance thanks to its minimal moving parts.

Score: 4.5/5

Model D: Heavy-Duty Performance and Reliability

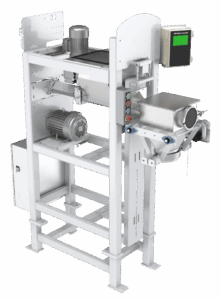

For facilities requiring robust and dependable bagging solutions, the Heavy-Duty Auger Open Mouth Bag Filler Model 2500 delivers exceptional performance. This machine features an auger feeder that uses a screw mechanism to transfer powders into bags, making it ideal for handling a variety of abrasive powders with ease and ensuring efficiency in high-demand environments.

Advantages:

- Constructed with thick wall box steel tubing for durability and rugged use.

- Features a dust-tight bag filling clamp to minimize dusting during operation.

- Equipped with a heavy-duty auger feeder that ensures reliable product flow with low maintenance needs.

With the Model 2500, you gain a reliable and efficient bagging solution that maintains productivity while accommodating various production settings.

Score: 4.5/5

Model E: Hygienic and efficient

The Clean-Duty Model 2550 Auger Open Mouth Bag Filler is an exceptional solution for businesses that require efficient bagging of various powders, such as salt and other granular products, particularly in hygienic environments. This machine excels in applications where thorough cleaning is crucial to prevent cross-contamination.

Special Features:

- Dust-tight filling: The bag filling clamp secures bag tops to minimize dusting during the filling process.

- Heavy-duty auger: Designed with low-maintenance shaft seals, it reliably feeds products into bags with precision.

- Quick cleanup: Interior components, including the auger and agitator, are engineered for easy removal, allowing for swift cleanup and inspection with minimal tools.

With the capability to hold up to 70 lbs. bags securely via an air-operated clamp, the Clean-Duty Model 2550 is self-standing and easily portable, making it suitable for multiple production locations. Its low head height allows for efficient use of space in any facility, ensuring it fits seamlessly into various setups.

Score: 4.5/5

Conclusion

Choosing the right open mouth bagger can significantly influence the efficiency and effectiveness of your packaging processes. These five models from Choice Bagging Equipment offer a range of functionalities suited for different applications, ensuring that you find the ideal solution for your business. From high-speed efficiency to custom packaging needs, invest in a bagging machine that aligns with your production goals, and elevate your operational efficiency to new heights.

Frequently Asked Questions

What are open mouth bagging machines used for?

Open mouth baggers are utilized for efficiently packaging materials like powders and granules across industries such as agriculture, chemicals, and food, ensuring precise filling and minimal waste.

How does the Model NWB-AF open mouth bagger perform?

The Model NWB-AF can fill bags weighing between 20 to 110 lbs at speeds of 1 to 12 bags per minute, making it suitable for a variety of products like fertilizers and pet food.

What makes the Industrial-Duty Auger Valve Bag Filler unique?

This model, known for its high-speed efficiency, is designed for demanding environments and includes features like dust seals to maintain clean operations while optimizing throughput.

What should I consider when selecting an open mouth bagging machines?

Consider factors such as the type of materials you’re packaging, required speed, space for installation, and the need for customization to fit your operational goals.

Can open mouth baggers handle unique packaging requirements?

Yes, models like the Concetti IPF Automatic Bagging Machine are designed to adapt to specific packaging needs, filling small gusseted bags with efficiency and reliability.

Recent Comments