In modern industrial packaging, valve bag fillers are central to boosting productivity, reducing product loss, and meeting compliance standards. At Choice Bagging, we provide bagging equipment solutions tailored to the specific needs of industries ranging from cement and chemicals to food and agriculture, helping businesses achieve reliable packaging automation. Our machines deliver reliable solutions for a wide range of packaging challenges.

This guide covers the top valve bag filler machines, explores filling technologies (auger vs impeller vs gravity vs air vs vacuum), and offers insights into cost, ROI, maintenance, and durability.

What Are Valve Bags?

Valve bags are specialized containers with a self-closing valve that allows clean, efficient filling of powders, granules, and pellets. They are widely used for products such as:

- Cement, fly ash, gypsum, fertilizer

- Flour, sugar, starch, cocoa, spices

- Plastic pellets, resins, hydrated lime

- Granular products such as seeds and fertilizers

- Fibrous or compressible materials like soils, sawdust, and cellulose fiber

These bags have what’s called a fill spout or filling spout (also referred to as the spout). It’s a key component in the filling process, ensuring accurate product transfer and minimizing dust. The fill cycle is the phase when the product is actively transferred into the bag. Both work in tandem in order to create a smooth, high quality process.

By integrating powder packaging machines with valve bags, manufacturers improve fill accuracy, reduce dust emissions, and comply with OSHA dust control standards and food-grade certifications.

Types of Valve Bag Filling Machines

As we’ve mentioned previously, these machines are suitable for packaging a variety of products, including dry bulk materials, chemicals, and sand.

The range of valve bag filling machines can be selected based on operational needs and packaging requirements.

Different industries demand different filling systems. Here’s how they compare:

| Filling Method | Best For | Pros | Cons |

| Auger | Fine powders (cement, flour, fertilizer, chemical powders, sand) | Precise dosing, low spillage, uses a horizontal screw for conveying powders | Higher wear on screw, periodic maintenance |

| Impeller | Dense powders (fly ash, minerals, chemicals, sand) | Fast fill rates, handles cohesive powders, impeller packers and impeller packer models available, including horizontal impeller designs | May entrap air, more energy use |

| Gravity | Free-flowing products (grains, pellets, dry bulk materials, sand) | Low cost, minimal maintenance, manual operation common, does not require an external power source | Slower, less accurate |

| Air (Pneumatic) | Lightweight materials (flour, starch, plastic pellets, dry bulk materials, chemical powders) | Fast, accurate, reduced dust, uses pneumatic packers (also called forced flow systems) that fill bags using air pressure | Higher power consumption |

| Vacuum | Ultra-fine powders (carbon black, fumed silica, chemical powders) | Gentle handling, high accuracy, uses a chamber for vacuum packing | Slower speed, higher cost |

Note: Valve bags differ from open mouth bags, which are filled using open mouth bagging machines designed for bags that are open at the top.

Key Considerations Before Choosing

1. Filling Speed & Capacity

- High-speed air packers: up to 10–12 bags per minute.

- Precision auger fillers: slightly slower, but critical for industries requiring exact weights (e.g., food packaging).

2. Cost & ROI

- Entry-level gravity fillers: low upfront cost but limited productivity.

- Automated auger/air packers: higher capital investment but ROI within 1–2 years due to labor savings, reduced waste, and compliance advantages.

3. Maintenance & Durability

- Auger screws: need routine wear-part replacement.

- Impellers: durable in heavy industries but require monitoring for blade wear.

- Forced-air fillers: need dust-control integration to meet OSHA standards.

4. Compliance

- Food-grade auger fillers (Model 2050) meet sanitation requirements (stainless steel, clean-in-place design).

- Dust-controlled air fillers (Model 7200) reduce airborne particulates, aligning with worker safety standards.

Types of Valve Bag Filling Machines on Choice Bagging

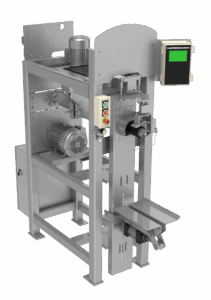

5. Industrial-Duty Auger Valve Bag Filler Model 2300

- Description: Designed for heavy-duty operations, this machine offers exceptional durability and speed, tailored for high-volume industries to achieve maximum efficiency without sacrificing accuracy. This model is ideal for packaging fertilizer in high-volume industrial settings.

- Pros: High durability; fast; suitable for large operations.

- Cons: Bulkier design; higher initial investment.

- Rating Score: 4.5/5

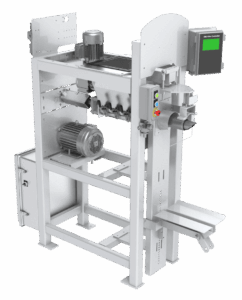

4. Clean-Duty Auger Valve Bag Filler Model 2050

- Description: This model is perfect for environments requiring high sanitation standards. With a robust design, it ensures precise filling while maintaining cleanliness—ideal for food-grade applications. It can also be equipped with a specialized sleeve to ensure proper sealing and hygiene in food-grade processes.

- Pros: High sanitation; precise filling; suitable for food products.

- Cons: May not be suited for heavy-duty applications.

- Rating Score: 4.7/5

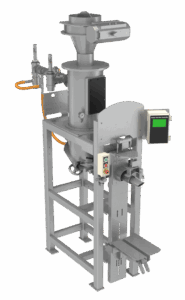

3. Abrasive-Duty Forced Air Valve Bag Filler Model 7200

- Description: Engineered for handling abrasive materials, this machine combines advanced forced air technology with heavy-duty construction, ensuring longevity and reliability in harsh environments. Abrasive materials are filled into valve bags with minimal dust and spillage, making it an ideal solution for packaging abrasive products. It is specifically designed to minimize dust emissions during the filling process, promoting a cleaner and safer work area.

- Pros: Durable; reliable for abrasive materials; efficient.

- Cons: More complex setup; maintenance may be required.

- Rating Score: 4.6/5

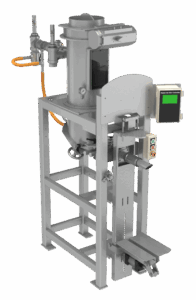

2. Digital Forced Air Valve Bag Filler Model 7300

- Description: Equipped with digital controls, this model offers enhanced precision and a user-friendly interface for easy adjustments, making it suitable for a variety of product types. The digital controls also help in minimizing product loss during the filling process and ensure each bag is filled to the exact required weight.

- Pros: Easy to use; precise; adaptable.

- Cons: Higher cost; dependent on electrical supply.

- Rating Score: 4.8/5

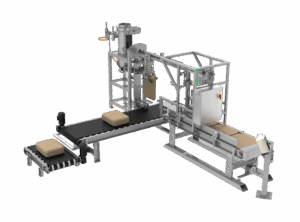

1. Automatic Valve Bag Placer Model 2700

- Description: Here’s our pick for the best overall for quality processing. This machine enhances automation in your packing line. Its efficient bag placement system minimizes downtime and maximizes workflow, making it a wise investment for busy production environments. This model can also be integrated into a complete packaging system for automated bag placement and filling, providing a comprehensive solution for your packaging process.

- Pros: Increases automation; minimizes downtime; enhances efficiency.

- Cons: Requires additional setup; investment cost.

- Rating Score: 4.9/5

Conclusion

Choosing the right valve bag filler machine is crucial for optimizing your production processes. At Choice Bagging, we believe each machine serves a unique purpose and understanding their features will help us select the best fit for our operations. Whether you require an auger, impeller, or forced air filling machine, investing in quality equipment will lead to increased efficiency, reduced waste, and improved product quality.

Frequently Asked Questions about Valve Bag Filler Machines

What are valve bag filler machines used for?

Valve bag filler machines are designed to efficiently fill and seal valve bags, commonly used for powders and granules in industries like agriculture, construction, and food processing.

How does an auger valve bag filler work?

An auger valve bag filler uses a helical screw to transport products into the bag, ensuring precise filling and minimal spillage, making it ideal for powders and similar materials.

What features should I consider when choosing a valve bag filler machine?

Key features include filling speed, capacity, material compatibility, and automation options, which all contribute to efficiency and productivity in your operations.

What distinguishes the Clean-Duty Auger Valve Bag Filler Model 2050?

The Clean-Duty Auger Valve Bag Filler Model 2050 is designed for high sanitation standards, making it suitable for food-grade applications with its precise and clean filling capabilities.

How can I ensure my valve bag filler machine is compatible with my product?

To ensure compatibility, assess the materials you plan to pack and select a machine that offers suitable filling techniques for your specific products, whether they are powders, granules, or liquids.

Can valve bag fillers handle lightweight materials?

Yes, air filling machines specifically cater to lightweight materials, providing faster filling speeds by utilizing compressed air, enhancing efficiency in the packing process.

Recent Comments