Valve Bag Filling Machines

Valve bag fillers are designed to rapidly and accurately package a wide range of granular and powdered materials. Typical products they bag include cement, minerals, fertilizer, resins, chemicals, flour, sugar, starch, and wood. Capable of packing 20-110 lbs. of material per bag, these machines are well-suited for manual, semi-automatic, and fully automatic manufacturing applications. They work by inserting a spout into the bag valve or opening during filling to control spillage and dust emissions.

Standard Valve Bag Filling Machines

Clean-Duty Auger Valve Bag Filler Model 2050

Fills an array of finely ground sanitary grade powders into valve bags. Ideal for applications requiring thorough equipment cleaning between uses.

Examples of materials this machine bags: flour, bakery mixes, cocoa, spices, pepper, animal grade pharmaceuticals, nutraceuticals, pigments, chemicals.

Fills up to 5 bags per minute.

(Note: combine up to 4 machines for higher rates)

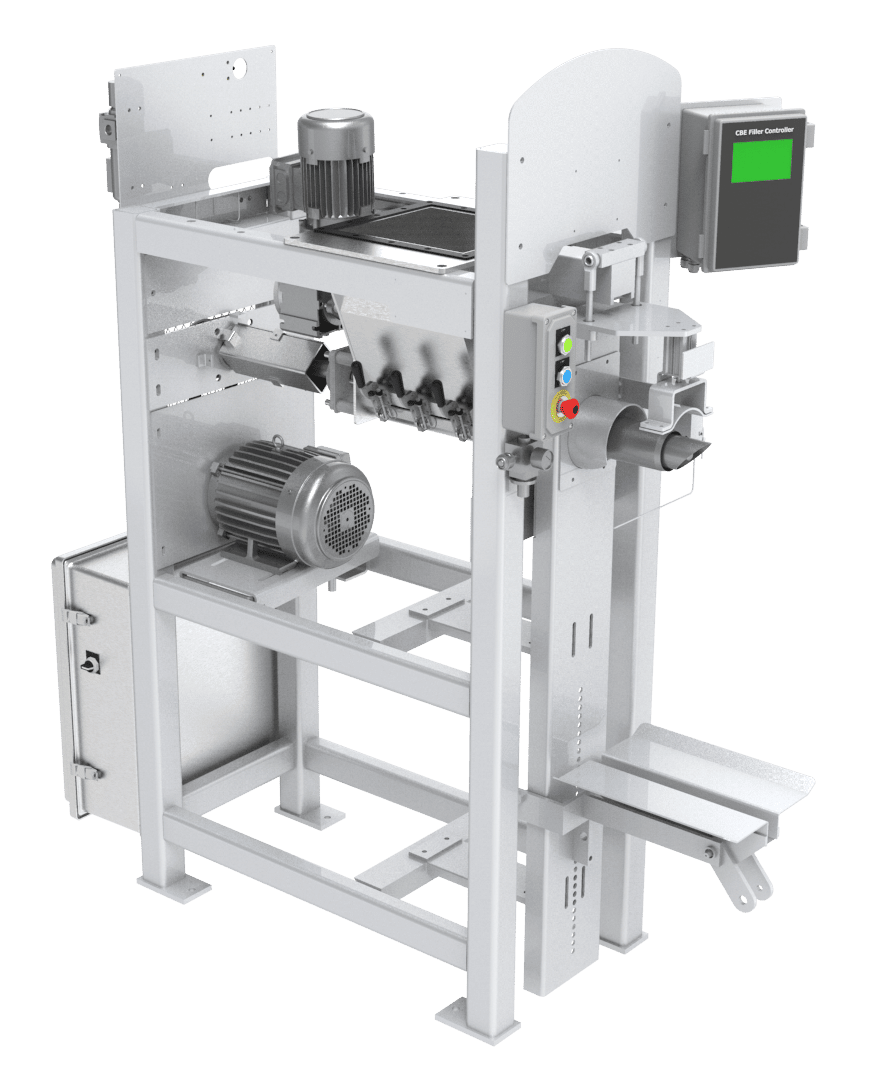

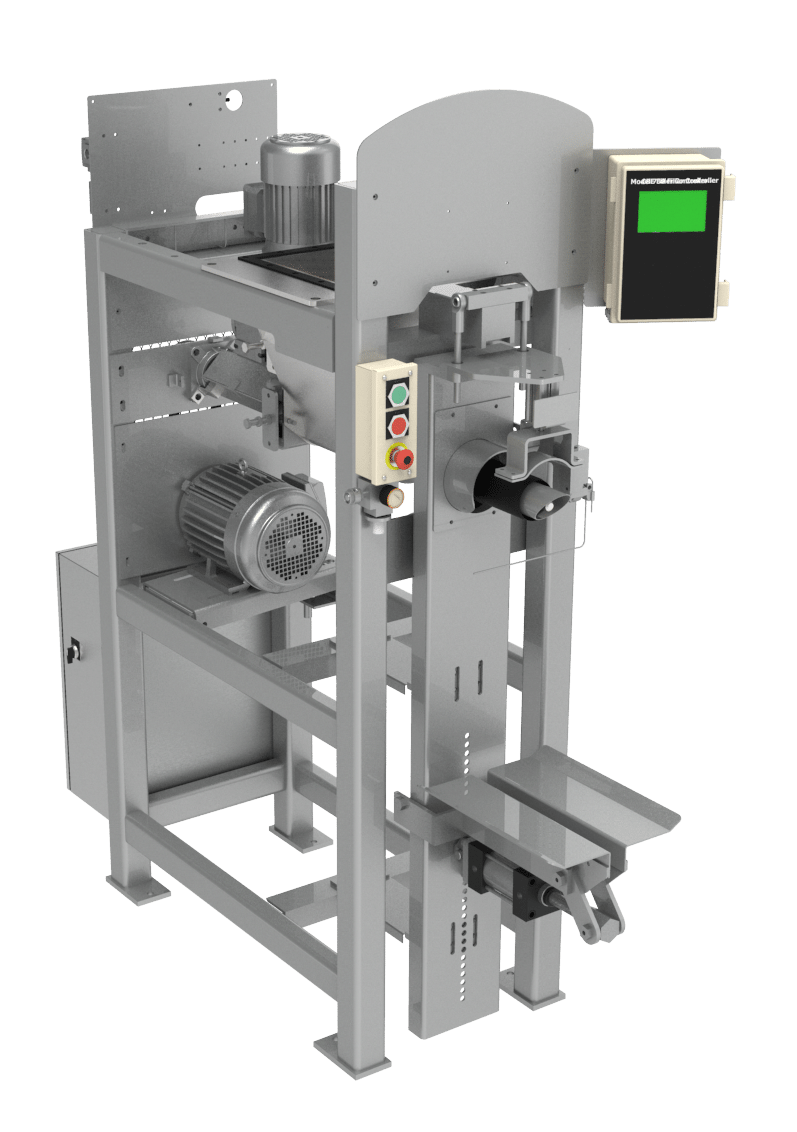

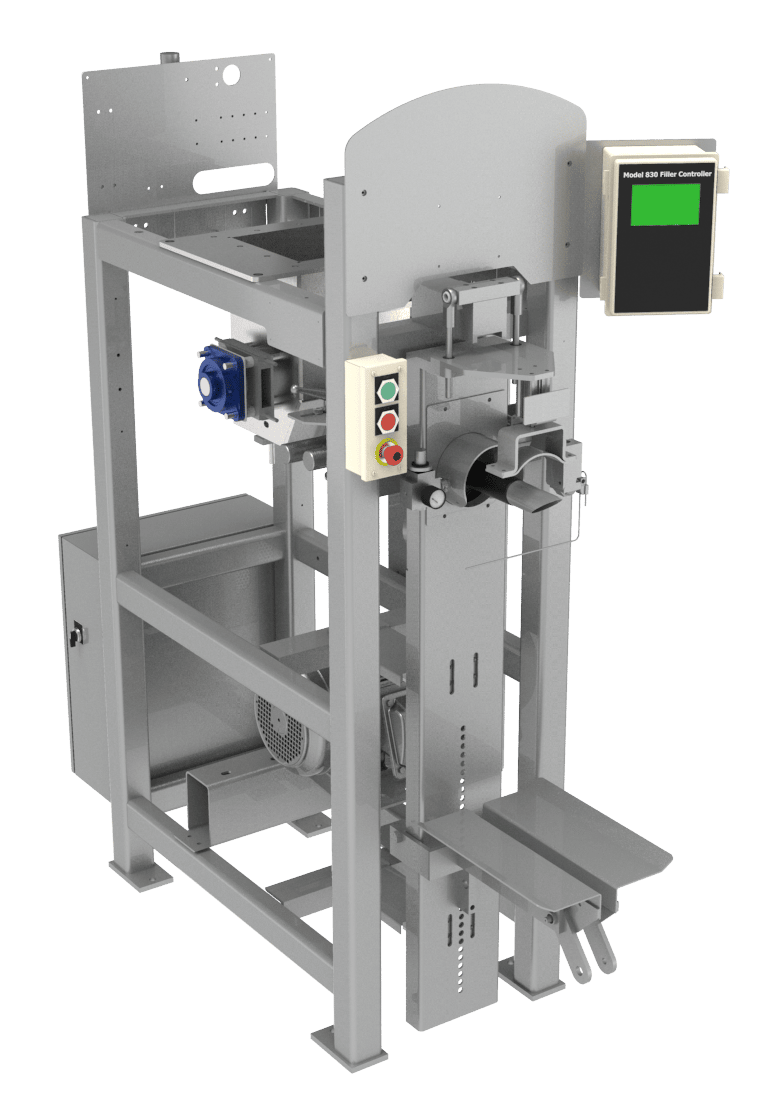

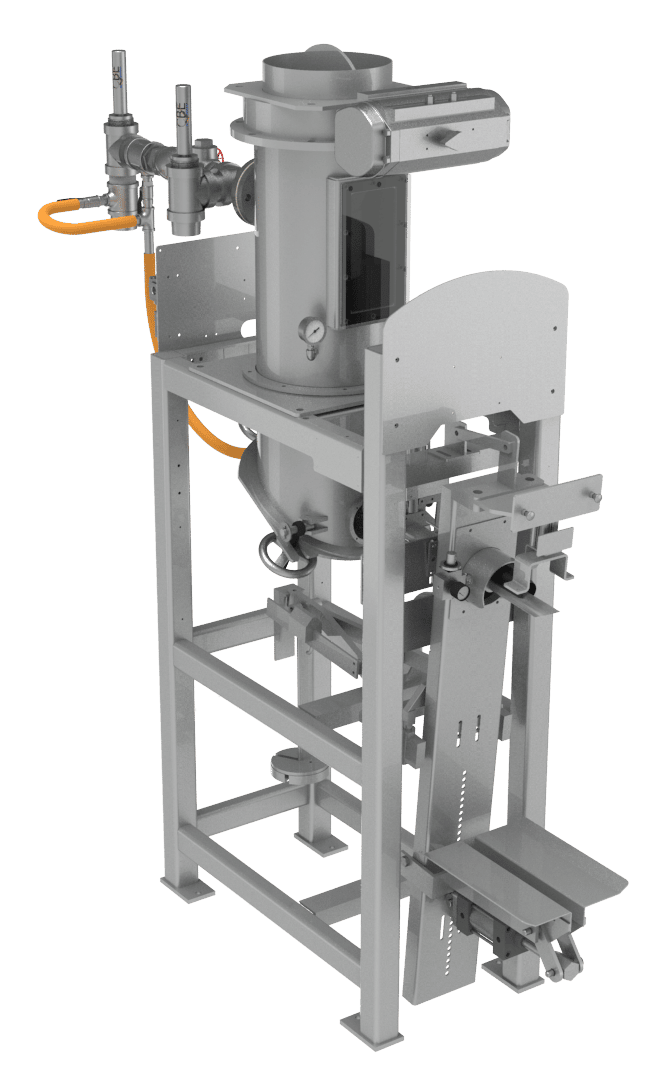

Industrial-Duty Auger Valve Bag Filler Model 2300

Packages a variety of finely ground industrial grade powders into valve bags. Designed for dependable performance in harsh, demanding environments.

Examples of materials this machine bags: mineral powders, cement powders, plaster, pigments, graphite.

Fills up to 5 bags per minute.

(Note: combine up to 4 machines for higher rates)

For filling a wide range of abrasives and high-density materials in valve type bags. Dependably packages abrasive products in harsh environments.

Examples of materials this machine bags: sand, garnet, concrete, stucco, limestone, granulated sugar, granulated salt, calcium carbonate.

Fills up to 10 bags per minute.

(Note: combine up to 4 machines for higher rates)

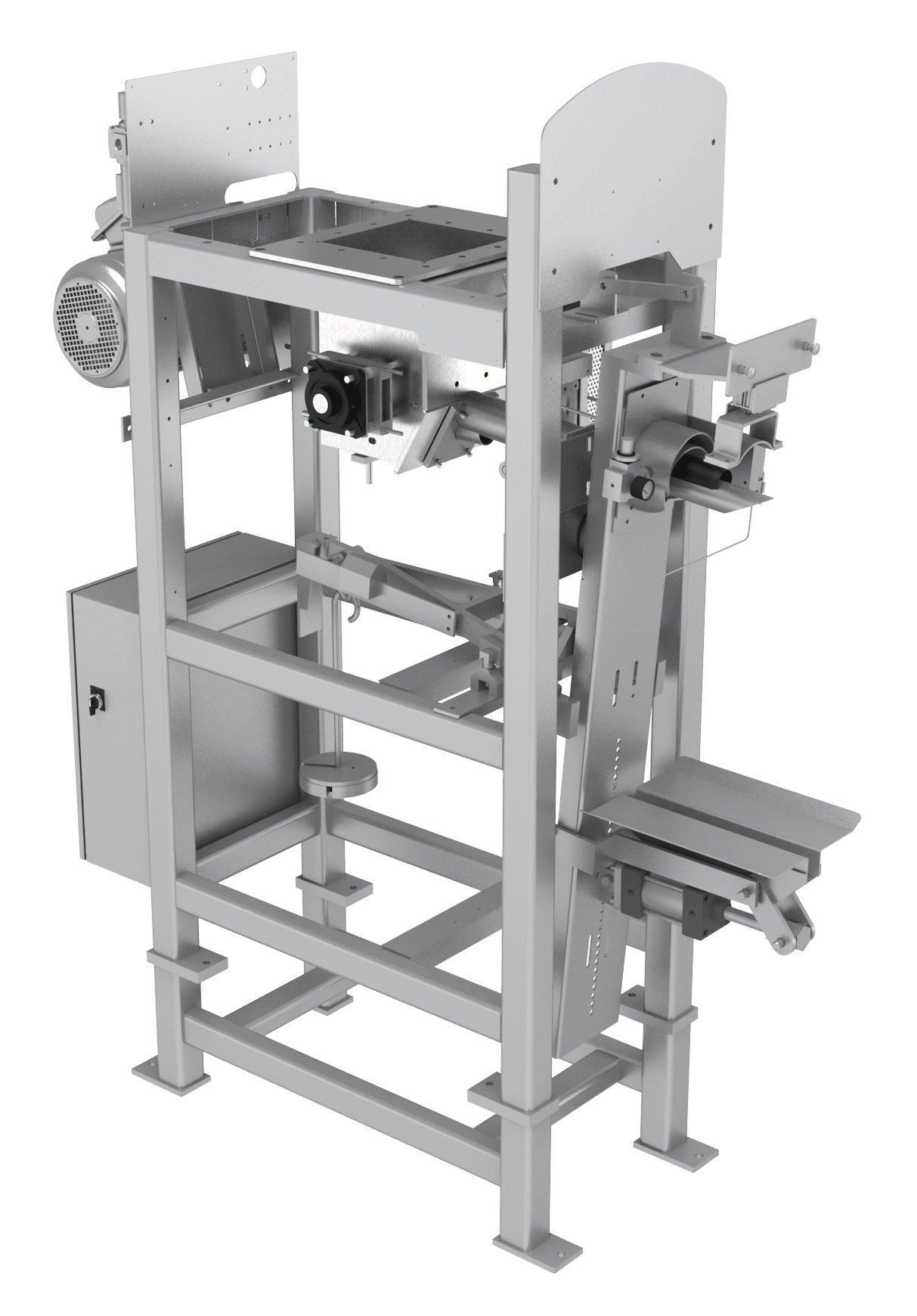

Dependable workhorse for clean, accurate filling. Bags a variety of powders, granules, pellets & powder / granule blends.

Examples of materials this machine bags: mortars, hydrated lime, gypsum, bentonite, barite, pigments, fertilizer, plastic pellets, plastic resins, calcium carbonate, starch, corn flour, oat flour, powdered sugar, hard grains.

Fills up to 10 bags per minute.

(Note: combine up to 4 machines for higher rates)

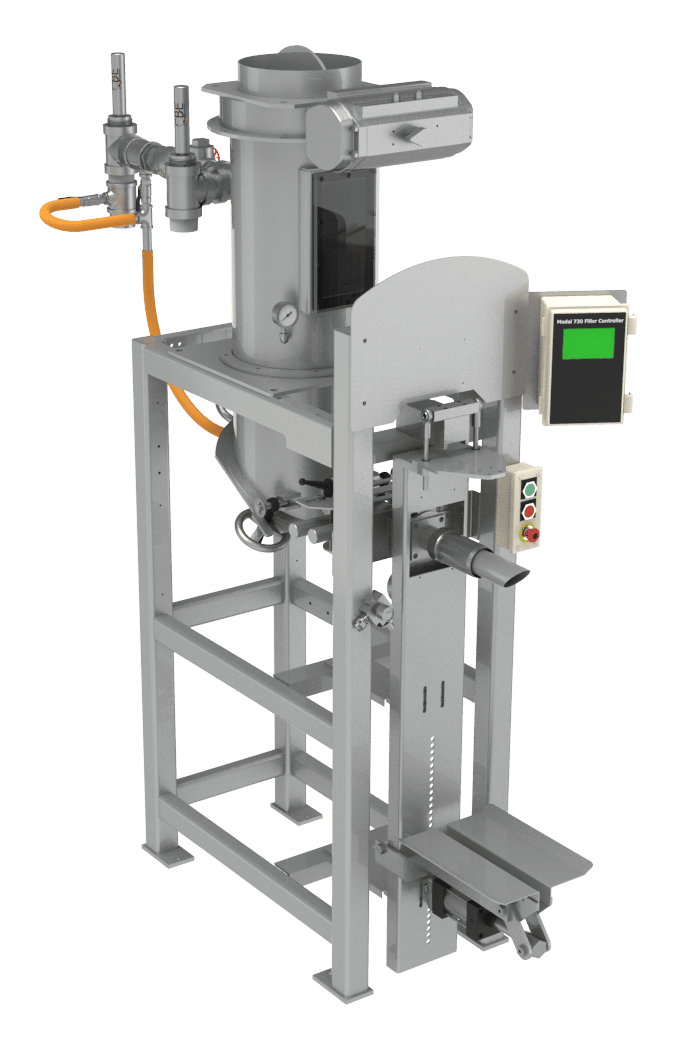

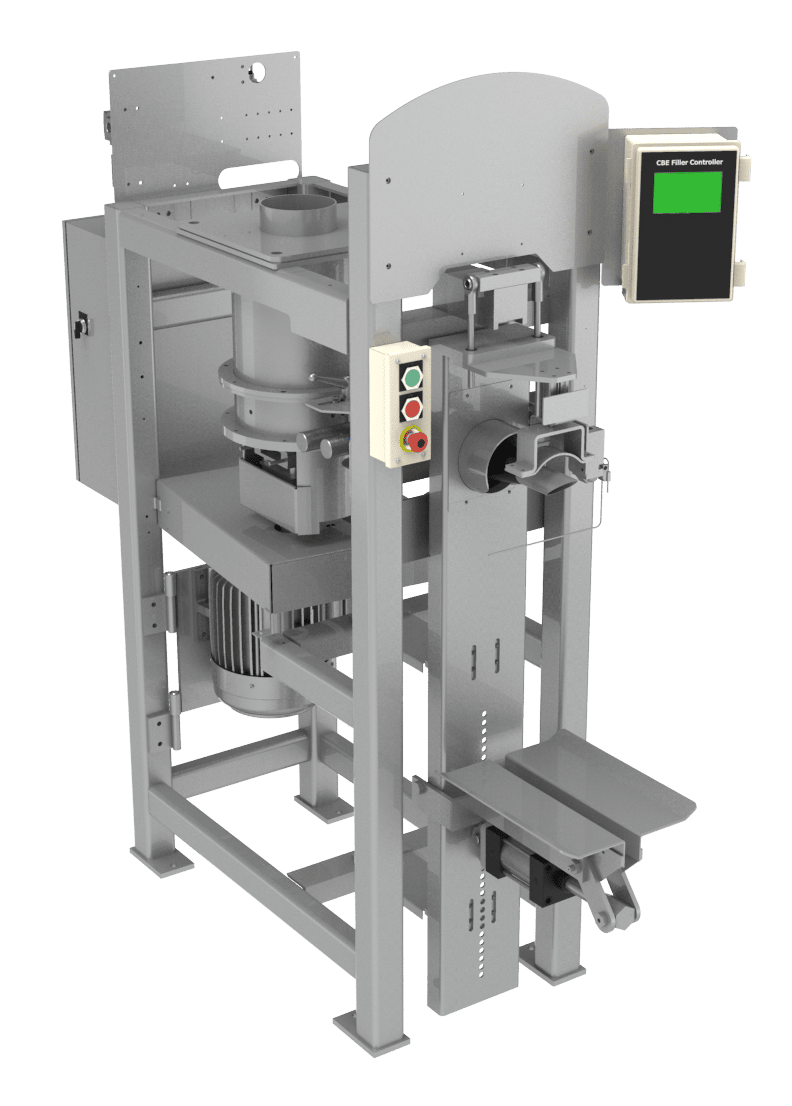

Vertical rotary vane bagger cleanly & efficiently packs a range of industrial grade powders and powder / granule blends of moderate specific gravity.

Examples of materials this machine bags: Portland cement, masonry cement, flyash, calcium carbonate, plaster, mortars, bentonite, gypsum.

Fills up to 8 bags per minute.

(Note: combine up to 4 machines for higher rates)

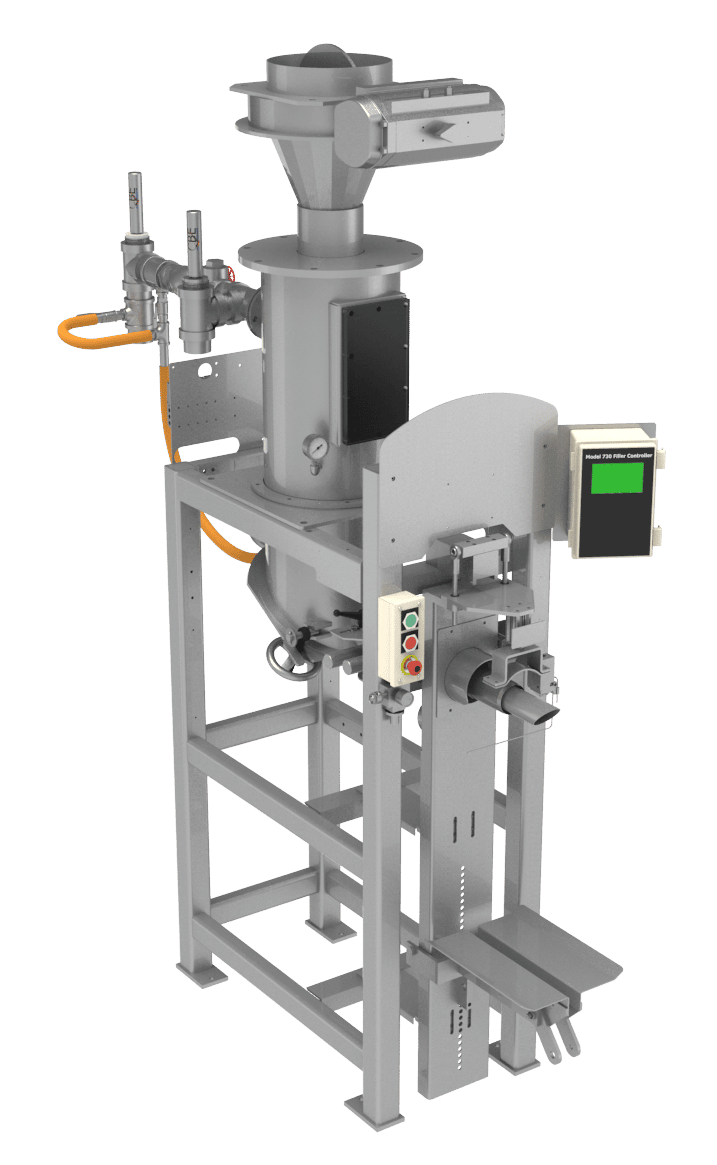

Horizontal rotary vane bag filler cleanly & efficiently packages many kinds of pulverized powders of light density / specific gravity.

Examples of materials this machine bags: talc, kaolin clay, hydrated lime, hydrated alumina, graphite, carbon black, activated carbon, silica fume, rice hull ash.

Fills up to 8 bags per minute.

(Note: combine up to 4 machines for higher rates)

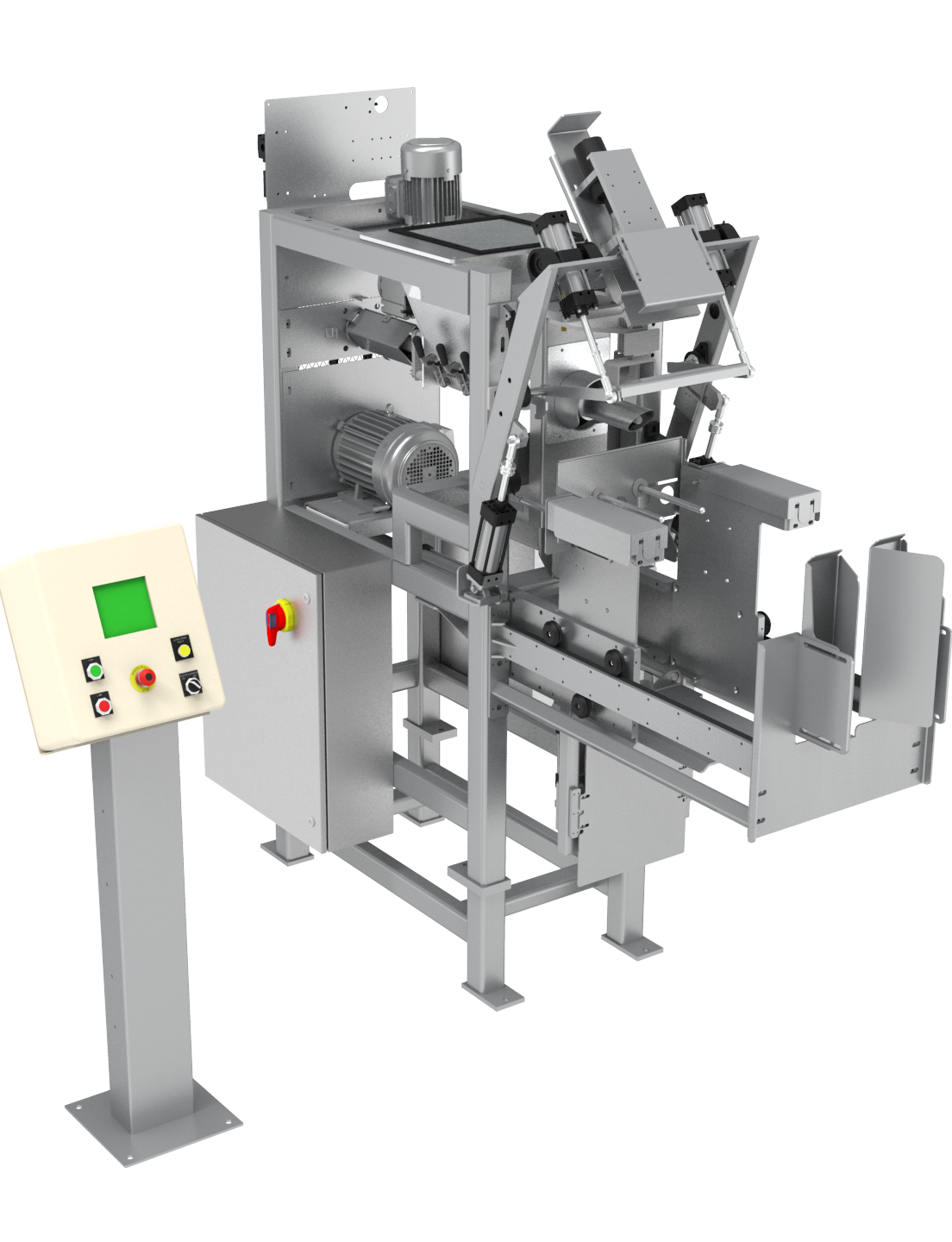

Automatically places valve bags on filler spouts and can be integrated with any CBE valve bag filler model.

(Note: combine up to 3 machines to achieve higher bagging rates)

Valve Bag Filling Machines for Specialty Applications

Mechanical Vertical Impeller Valve Bag Filler Model 8400

Bags a wide range of powders & powder / granule blends. Designed for commodity products at high speeds.

Examples of materials this machine bags: Portland cement, masonry cement, flyash, calcium carbonate, plaster, mortars, bentonite, gypsum.

Fills up to 14 bags per minute.

(Note: combine up to 3 machines for higher rates.)

Mechanical Forced Air Valve Bag Filler Model 7700

Fills moderate density powders and powder / granule blends in valve bags. Vertical rotary vane packs cleanly and efficiently.

Examples of materials this machine bags: sand, garnet, concrete, stucco, limestone, granulated sugar, granulated salt, calcium carbonate.

Fills up to 8 bags per minute.

(Note: combine up to 3 machines for higher rates)

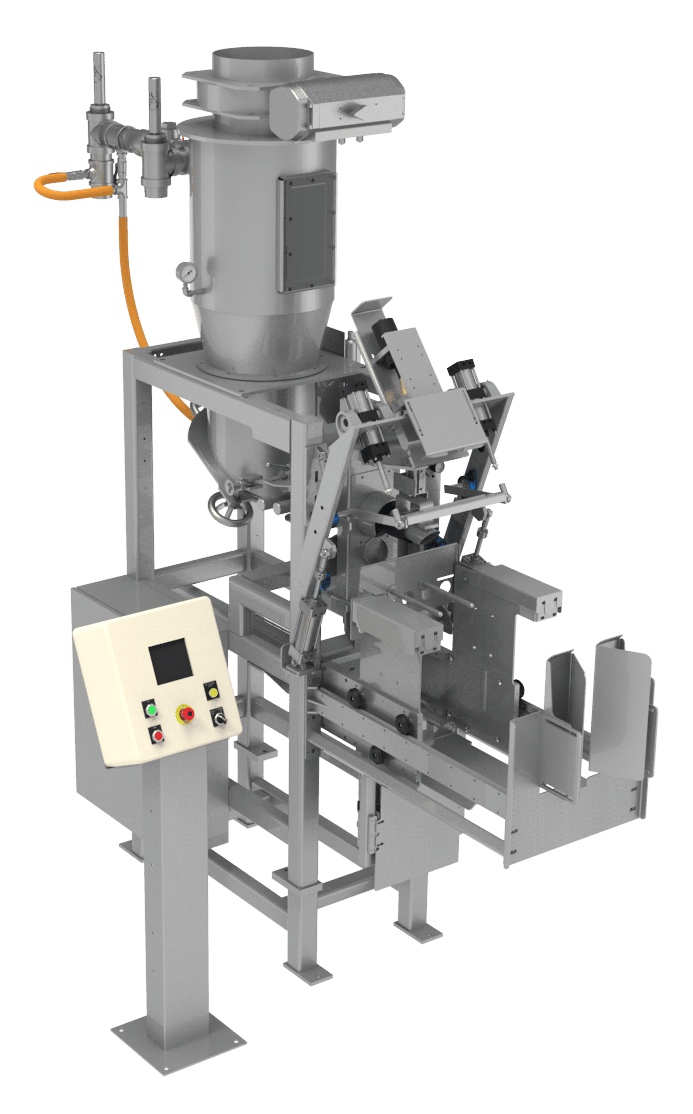

Bags and seals many types of finely ground sanitary grade powders. Ideal for applications requiring cleaning between uses.

Examples of materials this machine bags: flour, bakery mixes, cocoa, spices, pepper, animal grade pharmaceuticals, nutraceuticals.

Fills up to 3 bags per minute.

(Note: combine up to 3 machines for higher rates)

Sonic Seal Forced Air Valve Bag Filler Model 7550

Bags and seals powders, granules & powder / granule blends. Handles products gently.

Examples of materials this machine bags: starch, corn flour, oat flour, powdered sugar, calcium carbonate, pelleted carbon black, activated carbon, copper sulphate, pigments, plastic pellets, resins & chemicals powders.

Fills up to 3 bags per minute.

(Note: combine up to 3 machines for higher rates)

What are Valve Bags and How Do They Work?

Valve bags are pre-formed with a fill spout, or valve, in one corner to allow for fast and easy filling. After the bag is filled, the valve’s inner flap functions as a self-closing check with no secondary sealing required. On a worldwide basis, the versatile valve bag is used more than any other bag type. This is because the valve sleeve can be manufactured in a variety of styles for different applications. They include poly, tuck-in, heat seal, and sonic-seal valve sleeves. Valve bags can also be equipped with PE-free film or PE-liners when enhanced moisture protection is needed. Valve bag machines from Choice Bagging are capable of filling 20-110 lbs. (9-50KG) valve bags with flaked, powdery, and/or granular products at rates up to 24 bags per minute or 1,440 per hour.

Applications & Names for Valve Bag Fillers

Valve bag filling machines are most commonly used to bag products like cement, concrete, minerals, fertilizer, resins, chemicals, flour, starch, feed, salt, sugar and wood. They’re most frequently referred to as valve bag packing machines, valve bag packers, or air packers.

Examples of Materials Packaged with Valve Bag Fillers:

Building Materials

Cement, Concrete, Stucco, Grout, Plaster, Sand, Refractories

Food Products

Flour, Sugar, Salt, Cake Mixes, Cocoa, Spices, Bakery Mixes

Industrial Minerals

Graphite, Garnet, Barite, Bentonite, Gypsum

Agricultural

Feed, Seed, Fertilizer,

Wood Pellets

Chemicals

Plastic Pellets, Fertilizer, Hydrated Lime, Zinc Oxide, TIO2, Iron Oxide, Carbon Black

The 3 Types of Valve Bag Fillers

Air Packers:

Sometimes referred to as Forced Flow or Pneumatic Packers, Air Packers are often used for filling bags with free-flowing, low humidity, dry flakes, powders & small size granules that cannot be heated, ground, or crushed.

Applications:

- mortars

- sugar

- calcium carbonate

- PVC pellets

- limestone

Impeller Packers:

Sometimes called Turbine Packers, Impeller Packers are used for dry, high bulk density powders at 200 mesh or finer where crushing or fineness are not concerns.

Applications:

- fly ash

- carbon black

- portland and masonry cement

- kaolin

- clay

- graphite

- silica

- activated carbon

Auger Packers:

Often called Screw Baggers, Auger Baggers are designed for flakes, powders, pellets, granules, and fibrous material.

Applications:

- cellulose

- fiber

- compost

- flour

- insulation

- limestone

- minerals

- pepper

- pigment

- plastic pellets

- resins

- crumbled rubber

- salt

- sand

- sawdust

- bakery mixes

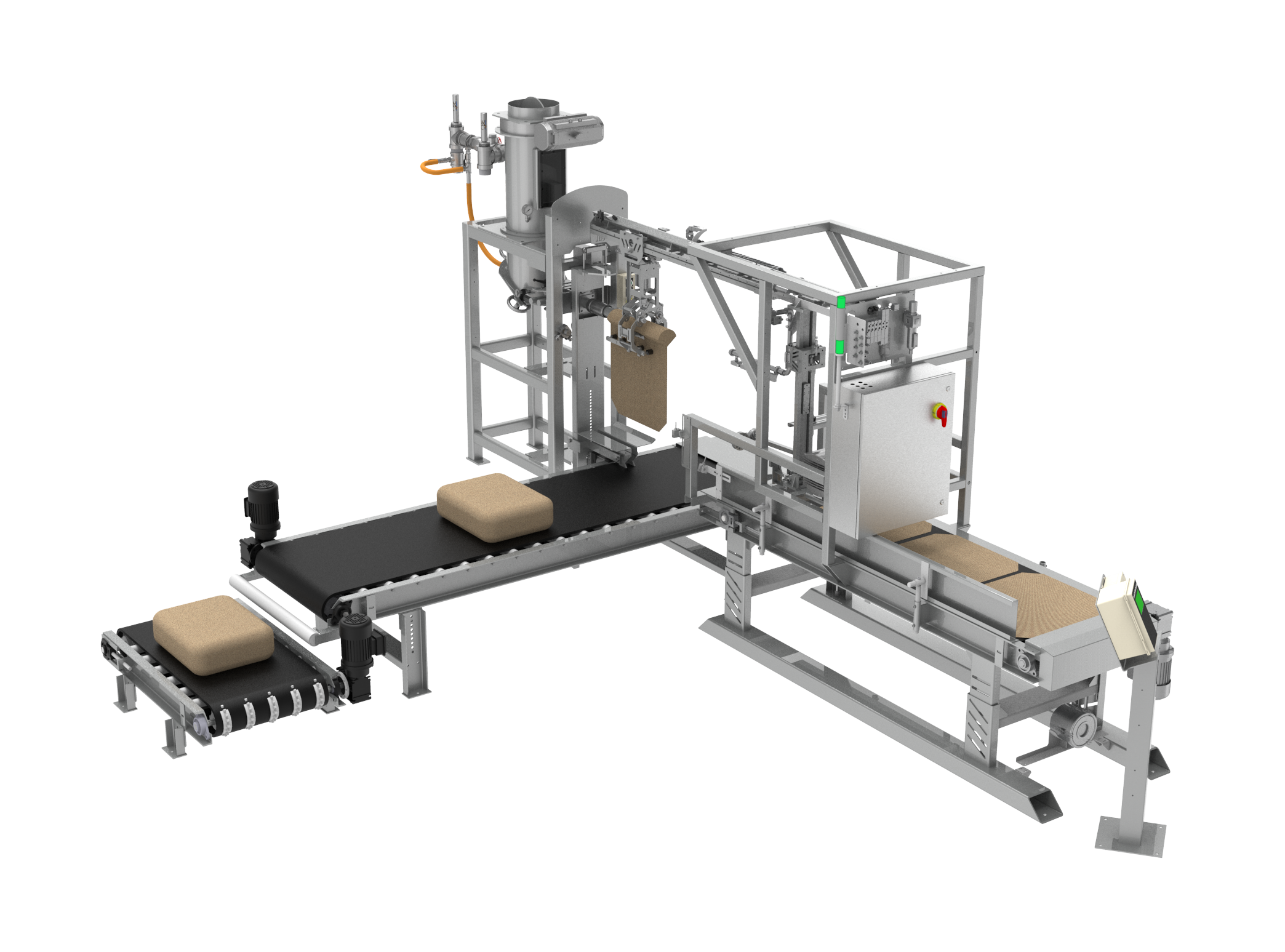

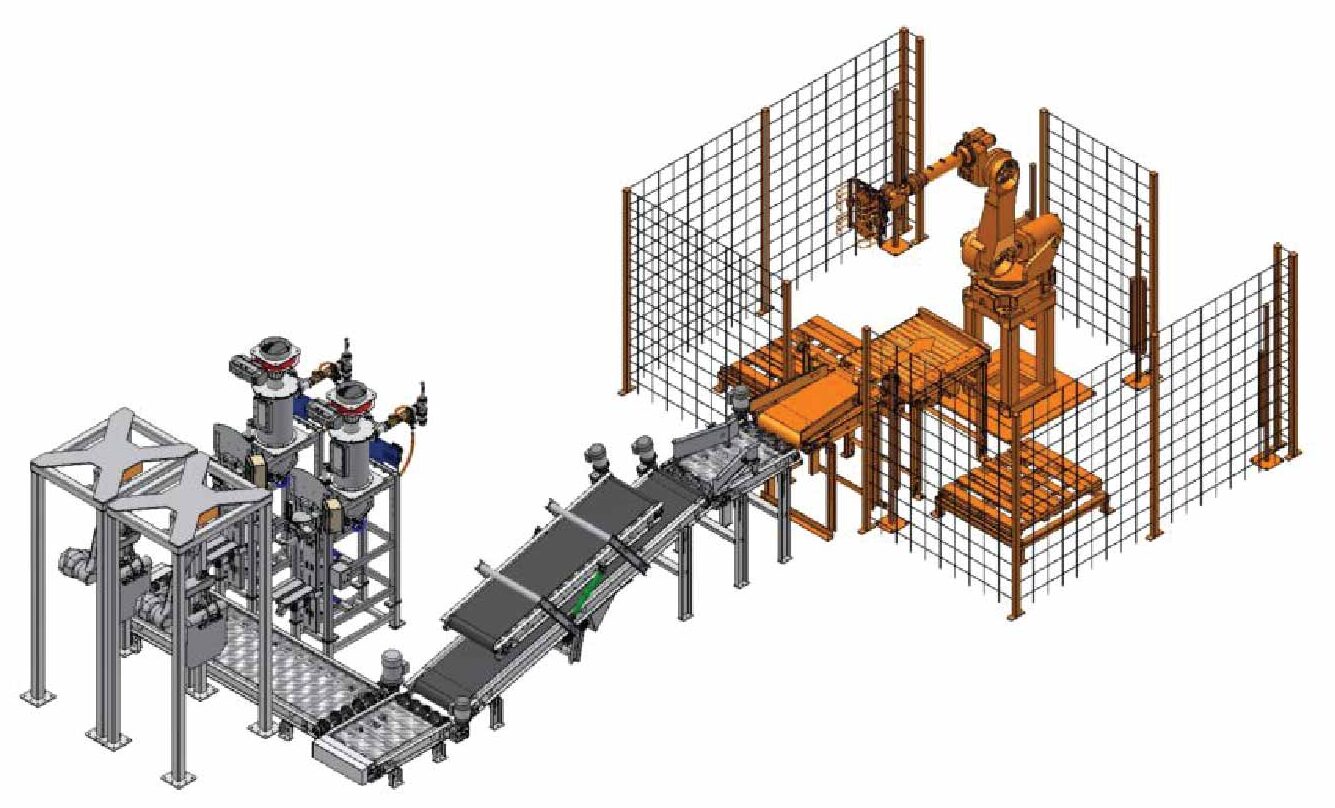

Advanced Systems with Valve Bag Filling Machines

For high-volume production environments, valve bagging systems are configured with multiple bag filling machines in a row. The line can also be supplemented with automatic bag placers and automated robotic bag palletizing systems. Systems like this can bag and stack up to 1,440 bags per hour, per line.

The line can be further automated by adding bag flattening conveyors, weight checkers, bag printing systems, metal detection systems, and non-conforming bag rejection conveyors. Stretch wrappers and pallet wrappers are also available for applying load protection after bag palletizing. Systems like this reduce reliance on human labor and provide vastly increased productivity.

We Can Help Choose a Valve Bag Filler

Choosing the correct valve bag filler for your needs is a massive challenge to undertake. Fortunately, the bagging machine experts at CBE can help you make the best decision based on your specific requirements.

CHOICE BAGGING EQUIPMENT

4804 N Main St,

Taylor, TX 76574

Hours

Monday-Friday 8am-5pm

Saturday & Sunday: Closed