by Choice Bagging | Sep 6, 2021 | Case Studies, Rebuilt bagging equipment

Rebuilt bagging equipment is a great option for many companies Let’s take a look at how Bagger ER.™ Equipment Rebuilding Service brings new life to old workhorses. Time, wear, and tear eventually take a heavy toll on a machine’s ability to...

by Choice Bagging | Sep 5, 2021 | Auger Bag Filler, Case Studies

With most auger bag fillers, auger removal for cleaning or machine maintenance is time-consuming and requires a technician with the mechanical skill to disassemble, reassemble and properly align the auger before the machine can be run again. The entire process...

![Open Mouth Bagging System for Deer Corn [Model GB]](https://www.choicebagging.com/wp-content/uploads/2021/09/Model-GB-Open-Mouth-Bag-Filler-11.jpg)

by Choice Bagging | Sep 5, 2021 | Case Studies, Food, Open Mouth Fillers

A producer of deer corn in central Texas was seeking a simple, entry-level open-mouth bag filling system to fill 40-50 pound bags at a rate of 240 bags per hour. The client’s facility had minimum headroom and a limited amount of floor space. Additionally,...

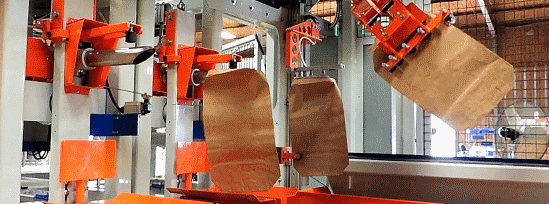

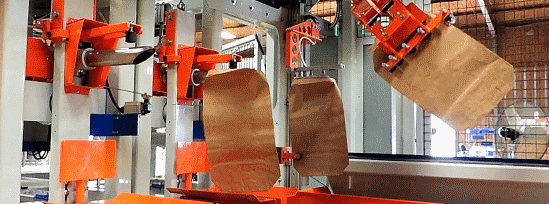

![Open Mouth Bagging Machine for Wood Pellets [Model GWB]](https://www.choicebagging.com/wp-content/uploads/2021/09/open-mouth-bag-filling-system-for-wood-pellets.jpg)

by Choice Bagging | Sep 5, 2021 | Agriculture / Landscaping, Case Studies, Open Mouth Fillers

A producer of wood stoves in New York was seeking an open-mouth bagging machine to package 3,000 pounds of wood pellets into 40-pound plastic bags to match the production rate of their pellet milling process. They wanted a system that would be fast, weight...

![Open Mouth Bag Filling System for Landscaping Materials [Model GWB]](https://www.choicebagging.com/wp-content/uploads/2021/07/Model-GWB-GV-Gravity-Vibrator-Open-Mouth-Bag-Filler-01.jpg)

by Choice Bagging | Sep 5, 2021 | Agriculture / Landscaping, Case Studies, Open Mouth Fillers

A producer of organic potting soils and landscaping products in Washington State was seeking an automated system for bagging its products. It had been using a manual line that was comprised of a combination of homegrown and purchased system components. The...

![Open Mouth Bag Filling System for Ice Melt (Calcium Chloride) [Model GWB-GV]](https://www.choicebagging.com/wp-content/uploads/2021/09/open-mouth-bag-filling-system-for-ice-melt-calcium-chloride.jpg)

by Choice Bagging | Sep 5, 2021 | Case Studies, Chemicals

A producer of Ice Melt products in northwest Arkansas was seeking an open-mouth bagging system to package 30,000 pounds per hour of its formulation into 20-50 pound bags. They wanted a system that would be fast, weight accurate and economical. Additionally, the only...

by Choice Bagging | Sep 5, 2021 | Case Studies, Production Tips

Regardless of which type of bag an operation uses – valve, open mouth, or bulk bag – the ultimate goal of virtually every industrial bagging operation is to fill and seal as many bags as possible cleanly and accurately within a specified time period. Yet while the...

by Choice Bagging | Sep 5, 2021 | Case Studies, Production Tips

Is upgrading bagging equipment or adding new machines the only way to increase capacity? There have been improvements in technology that make filling machinery faster, cleaner, and more weight accurate. But many times you might be costing yourself valuable production...

by Choice Bagging | Sep 5, 2021 | Case Studies, Service

Over the years, we have provided service for bag fillers of every brand, and every age. In many cases, the older machines are the best built. As it turns out, the old adage “They don’t build them like they used to” also applies to bagging machines. If you can find...

by Choice Bagging | Sep 5, 2021 | Case Studies, Service

We recently supplied one of our auger fillers to a producer of specialty sugar in central New Jersey. Shortly after startup, the customer began calling our bagging equipment service department complaining of poor bag weight accuracy that was way out of range of...

![Open Mouth Bagging System for Deer Corn [Model GB]](https://www.choicebagging.com/wp-content/uploads/2021/09/Model-GB-Open-Mouth-Bag-Filler-11.jpg)

![Open Mouth Bagging Machine for Wood Pellets [Model GWB]](https://www.choicebagging.com/wp-content/uploads/2021/09/open-mouth-bag-filling-system-for-wood-pellets.jpg)

![Open Mouth Bag Filling System for Landscaping Materials [Model GWB]](https://www.choicebagging.com/wp-content/uploads/2021/07/Model-GWB-GV-Gravity-Vibrator-Open-Mouth-Bag-Filler-01.jpg)

![Open Mouth Bag Filling System for Ice Melt (Calcium Chloride) [Model GWB-GV]](https://www.choicebagging.com/wp-content/uploads/2021/09/open-mouth-bag-filling-system-for-ice-melt-calcium-chloride.jpg)

Recent Comments